Formable and foamed aqueous compositions

A water-based composition, polymer technology, used in window decorations, textiles and papermaking, radiation-absorbing coatings, etc., can solve problems such as increasing the area of light-colored surface shadows

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0302] Preparation of Pigment Dispersions of Porous Particles:

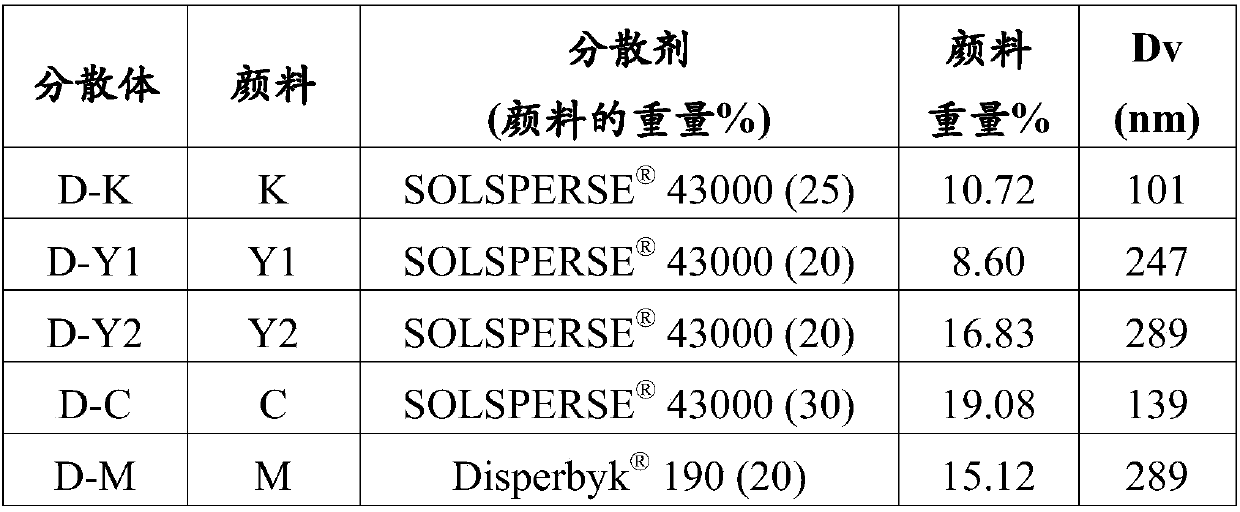

[0303] All pigment (opaque and tinting colorant) dispersions are prepared by combining dry pigment, dispersant and liquid in a suitable grinding vessel. Each pigment was reduced in particle size by milling using ceramic media until all pigment particles were reduced to below 1 μm in diameter as determined by optical microscopy. The dispersion is further diluted in the same liquid medium for incorporation into porous particles or foamable aqueous compositions. The dispersions varied in pigment type, dispersant type, level of dispersant relative to pigment, as shown in Table I below. Dv is the volume weighted mean diameter in nanometers. In Table I, dispersions are identified by pigment (K, Y1, Y2, C or M).

[0304] Table I Dispersion

[0305]

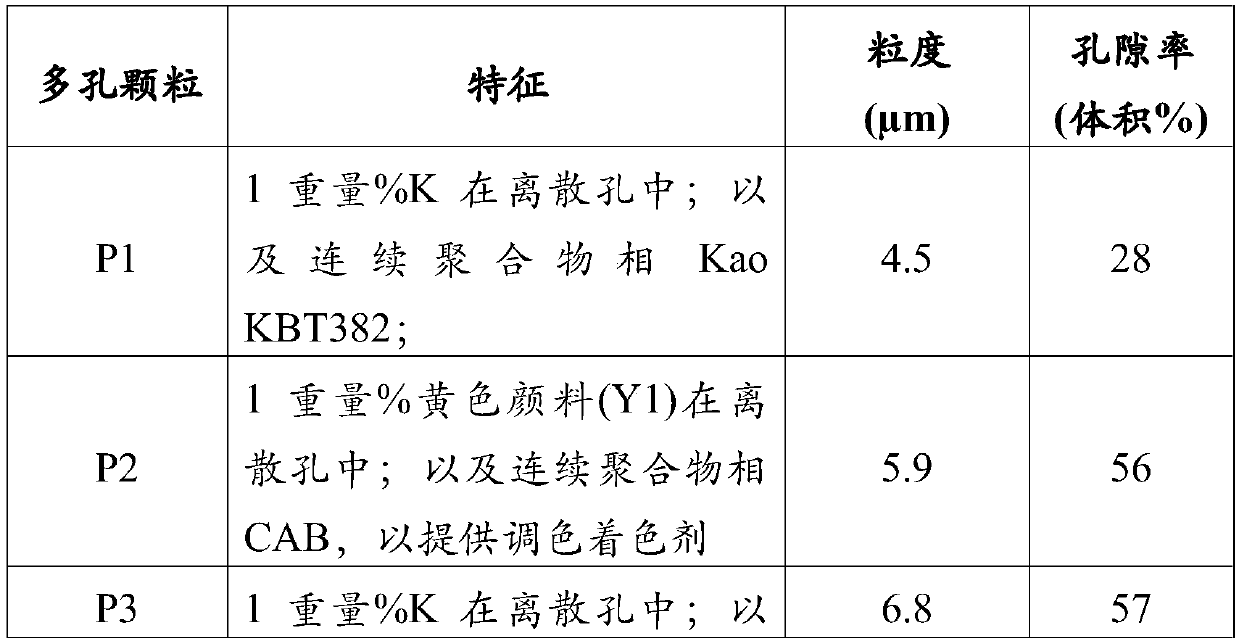

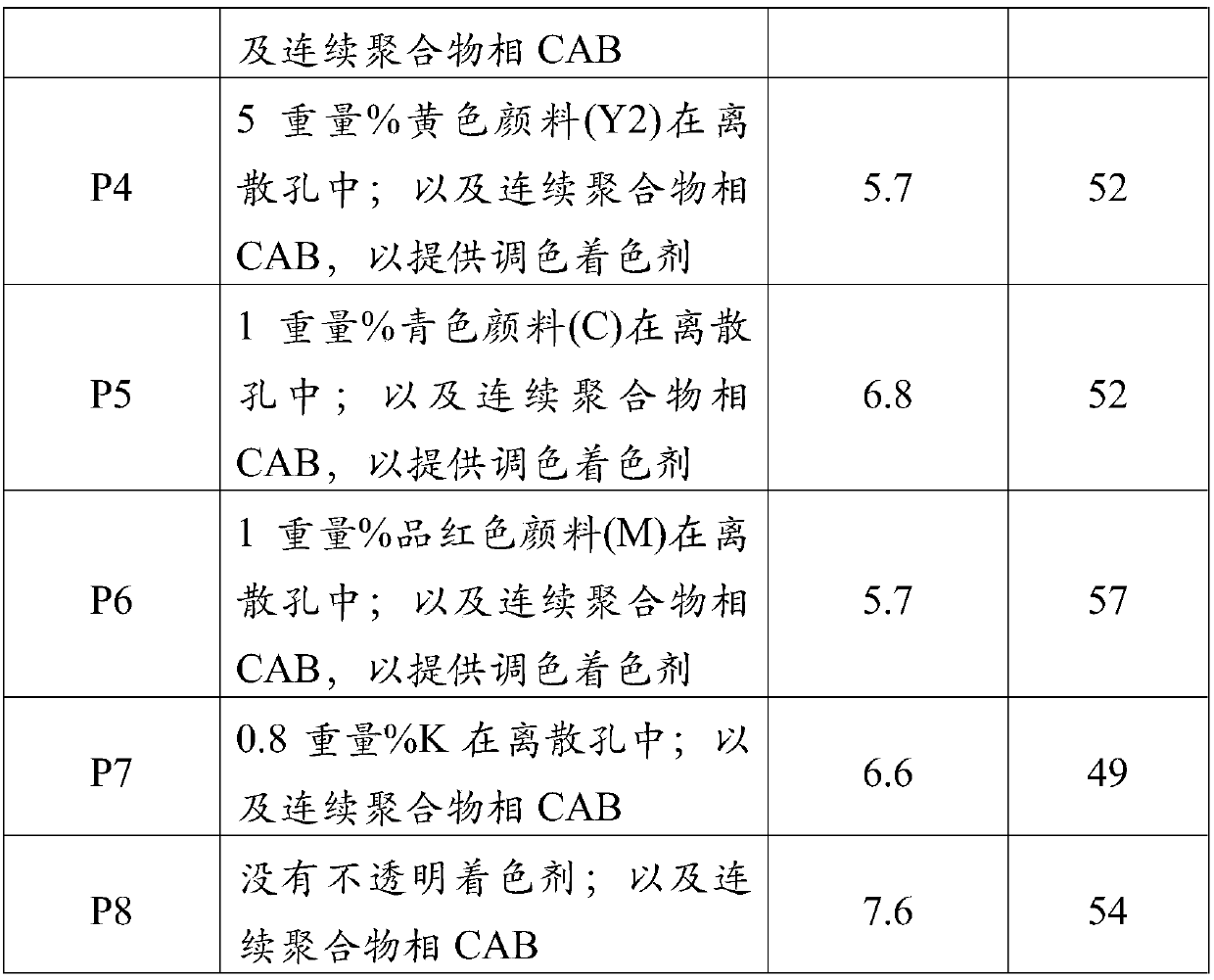

[0306] Preparation of porous particles:

[0307] The various porous particles used to prepare the foamed opaque elements used in the various inventive examples an...

Embodiment 1

[0336] by 940.3g A 49.76% by weight aqueous dispersion of C-3018 Drapery Compound and 59.7 g of P3 porous particles prepares a foamable aqueous composition according to the present invention. The foamable aqueous composition was foamed (aerated) to provide a foamable aqueous composition according to the present invention, which was applied to the above described on the surface of the porous substrate. The coating was dried as described in Comparative Example 1. The dry foam composition (dry opaque layer) contained 6.10% by weight of P3 porous particles, 0.0610% by weight of carbon black and 0.136 g / m 2 of carbon black. The resulting foamed opaque element exhibits a 2 LBV of 5 for the dry opaque layer weight, which is significantly more opaque than the foamed opaque element of Comparative Example 1. The foamed opaque element of the invention is also brighter in appearance, giving a higher light reflectance value of 53 compared to the light reflectance value of Comparative...

Embodiment 2

[0338] Use 1,399.8g A 49.25% by weight aqueous dispersion of C-3018 Drapery Compound and 100.2 g of P7 porous particles prepares a foamable aqueous composition according to the present invention. The foamable aqueous composition was foamed (aerated) and the foamable aqueous composition according to the present invention was coated as described in Comparative Example 2 using a coating knife with a gap of 2.54 mm (0.100 inches). onto the surface of the porous substrate described above. The dry foamed composition (dry opaque layer) in the foamed opaque element according to the invention contains 6.71% by weight of P7 porous particles, 0.0557% by weight of carbon black and 0.136 g / m 2 of carbon black. The foamed opaque element of the present invention exhibits a resistance to 244 g / m 2 The dry opaque layer weight has an LBV of 5.8, and it has a light reflectance value of 52.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| glass transition temperature | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com