Concentrated ginger juice and production process and application thereof

A production process and technology of ginger juice, applied to concentrated ginger juice and its production process and application field, can solve the problems of limited use of ginger juice, strong spicy taste, poor stability, etc., and achieve the preservation of aromatic flavor, high nutritional value and stability. Good results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0033] The embodiment of the present invention provides a kind of production technology of concentrated ginger juice, and it comprises the steps:

[0034] (1) Grinding the dried ginger slices into 20-40 mesh dried ginger powder;

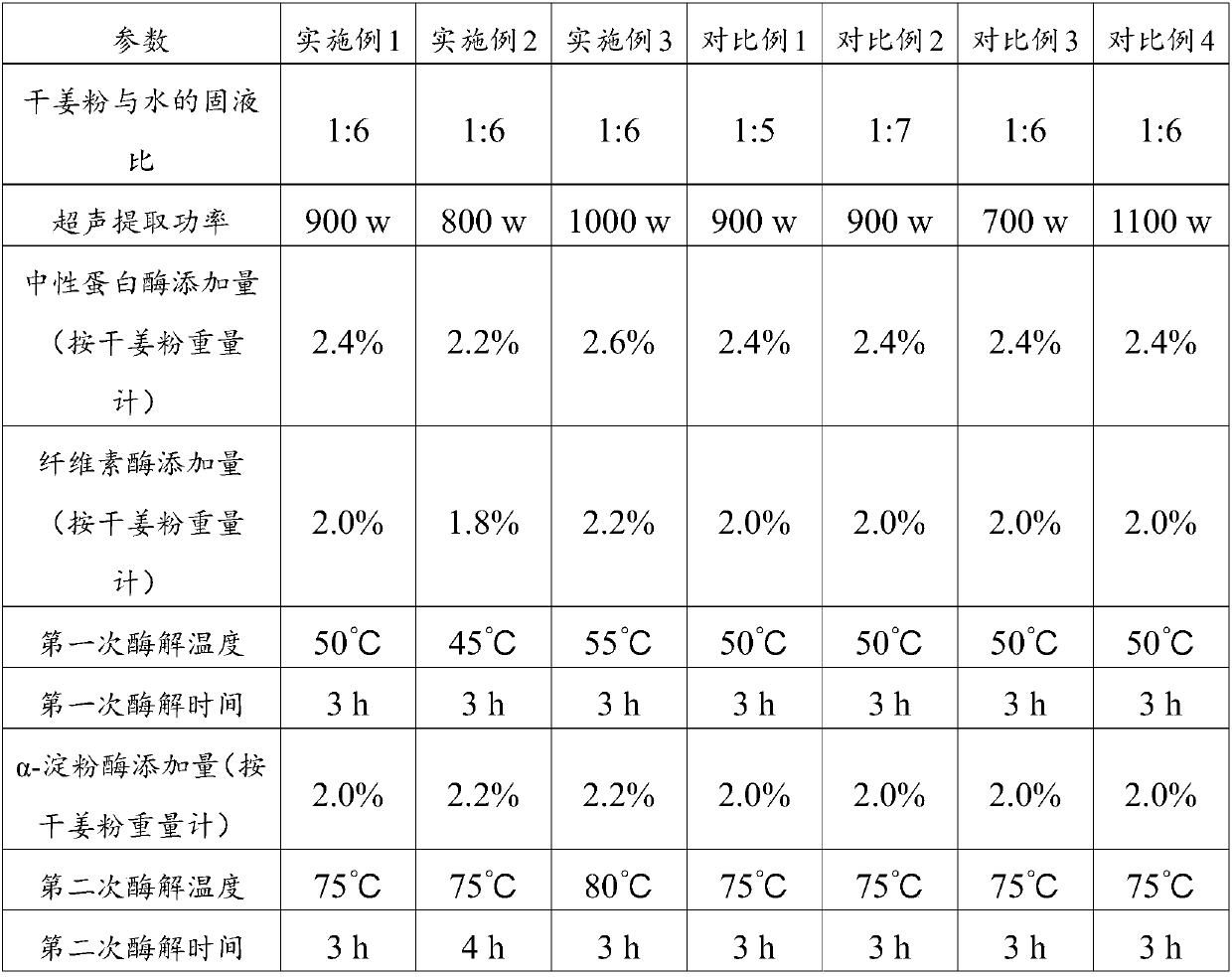

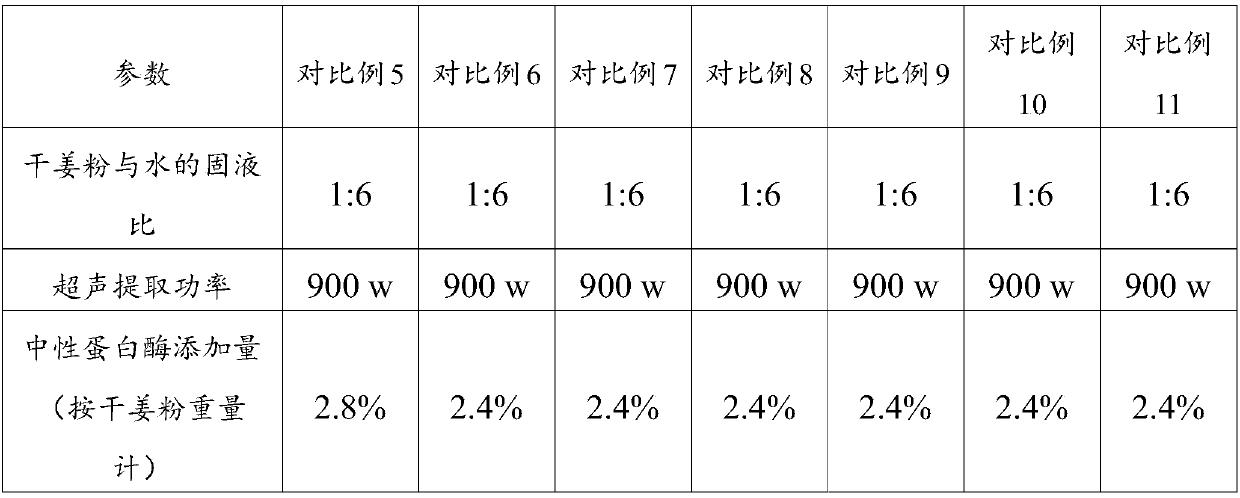

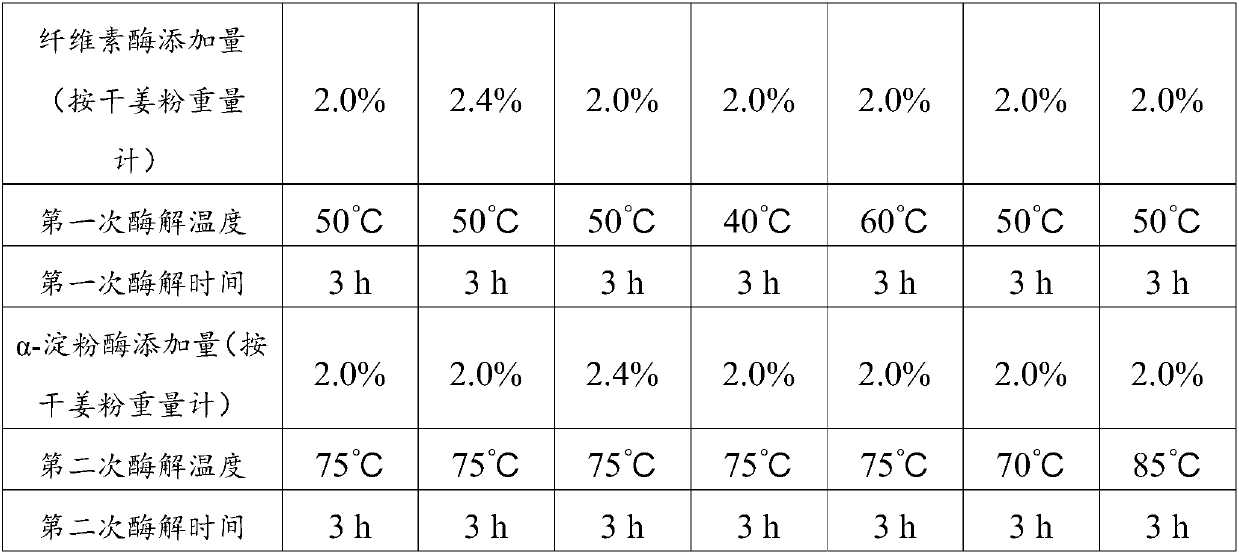

[0035] (2) Mix dried ginger powder with water (see Table 1 for solid-liquid ratio), and then insert an ultrasonic extractor (model: Jiemeng YM-1024) for ultrasonic extraction for 20 minutes (see Table 1 for ultrasonic extraction power);

[0036] (3) Add neutral protease and cellulase for the first enzymolysis (enzyme amount, enzymolysis temperature and enzymolysis time see Table 1), then add α-amylase for the second enzymolysis (enzyme amount , enzymolysis temperature and enzymolysis time see Table 1);

[0037] (4) Heat up to 95-100°C, keep warm for 20 minutes, inactivate the enzyme, separate the solid-liquid from the feed liquid with a centrifuge, then filter the filtrate with a 500-mesh filter, and finally evaporate and concentrate the filtrate to...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com