Preparation method of polypropylene/polydopamine compounded patch, compounded patch and application

A polydopamine and polypropylene technology, applied in the field of medical materials and their preparation, can solve problems such as easy displacement, and achieve the effects of simple production process, increased abdominal wall tension, and stable properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

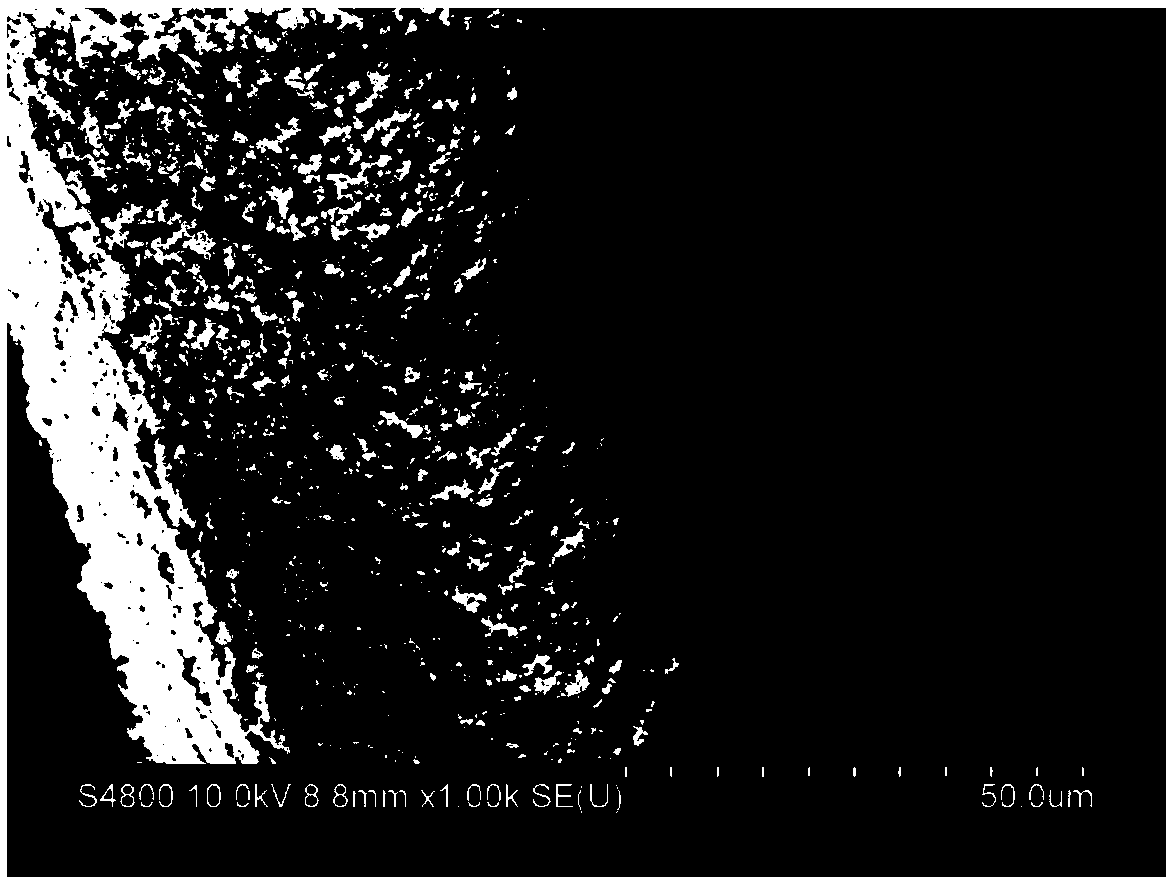

[0034] A polypropylene / polydopamine composite patch, which is a single-layer double-sided structure, one side is a polypropylene mesh surface, and the other side is a polypropylene / polydopamine film surface, that is, the other side is coated on the polypropylene mesh surface. Polydopamine film, its preparation process is as follows:

[0035] Step S1: Prepare 50mL of a 10mmol / L Tris solution, then add 0.12g of dopamine hydrochloride to prepare dopamine hydrochloride with a solubility of 2.4g / L, and add a piece of 2.5cm×2.5cm polypropylene mesh to the above solution The sheet was stirred and reacted in an air atmosphere at 28°C for 24 hours, then taken out, rinsed with distilled water and dried to obtain a polypropylene / polydopamine composite mesh material;

[0036] Step S2: adding sodium chloride into distilled water, continuously adding until it is configured as a saturated saline solution, and then, according to the volume of the saturated saline solution, adding sodium hypoc...

Embodiment 2

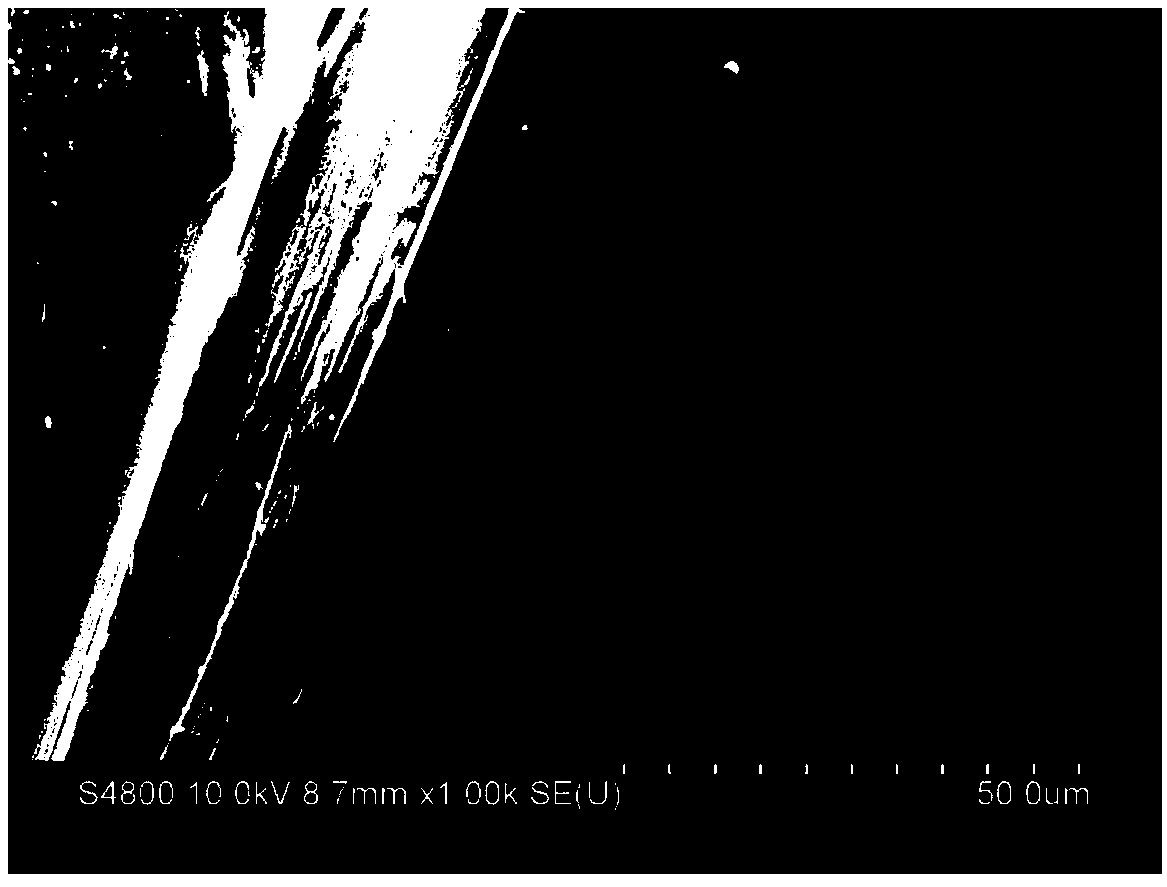

[0039] A polypropylene / polydopamine composite patch, which is a single-layer double-sided structure, one side is a polypropylene mesh surface, and the other side is a polypropylene / polydopamine film surface, that is, the other side is coated on the polypropylene mesh surface. Polydopamine film, its preparation process is as follows:

[0040] Step S1: Prepare 50mL of a 10mmol / L Tris solution, then add 0.12g of dopamine hydrochloride to prepare dopamine hydrochloride with a solubility of 2.4g / L, and add a piece of 2.5cm×2.5cm polypropylene mesh to the above solution The sheet was stirred and reacted in an air atmosphere at 28°C for 24 hours, then taken out, rinsed with distilled water and dried to obtain a polypropylene / polydopamine composite mesh material;

[0041] Step S2: adding sodium chloride into distilled water, and continuously adding until it is configured into a saturated saline solution, and then, according to the volume of the saturated saline solution, adding sodium...

Embodiment 3

[0044] A polypropylene / polydopamine composite patch, which is a single-layer double-sided structure, one side is a polypropylene mesh surface, and the other side is a polypropylene / polydopamine film surface, that is, the other side is coated on the polypropylene mesh surface. Polydopamine film, its preparation process is as follows:

[0045] Step S1: Prepare 50mL of a 10mmol / L Tris solution, then add 0.12g of dopamine hydrochloride to prepare dopamine hydrochloride with a solubility of 2.4g / L, and add a piece of 2.5cm×2.5cm polypropylene mesh to the above solution The sheet was stirred and reacted in an air atmosphere at 28°C for 24 hours, then taken out, rinsed with distilled water and dried to obtain a polypropylene / polydopamine composite mesh material;

[0046] Step S2: adding sodium chloride into distilled water, and continuously adding until it is configured as a saturated saline solution, and then, according to the volume of the saturated saline solution, sodium hypochlo...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com