A kind of full resource treatment method of sodium sulfate salt slag

A treatment method and technology of sodium sulfate, applied in chemical instruments and methods, alkali metal sulfite/sulfate purification, solid waste removal, etc., can solve the problem of difficulty in producing pure white sodium sulfate crystals, slow treatment process, and investment costs. Large and other problems, to achieve the effect of thorough purification, large processing capacity and simple process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0027] (1) Weigh 5g of sodium sulfate salt slag produced by the H acid process in a crucible, put it into a muffle furnace and roast for 2 hours at a roasting temperature of 250°C; dissolve the roasted solids in 20mL of water and stir with a magnetic force Stir until the salt mud is completely dissolved;

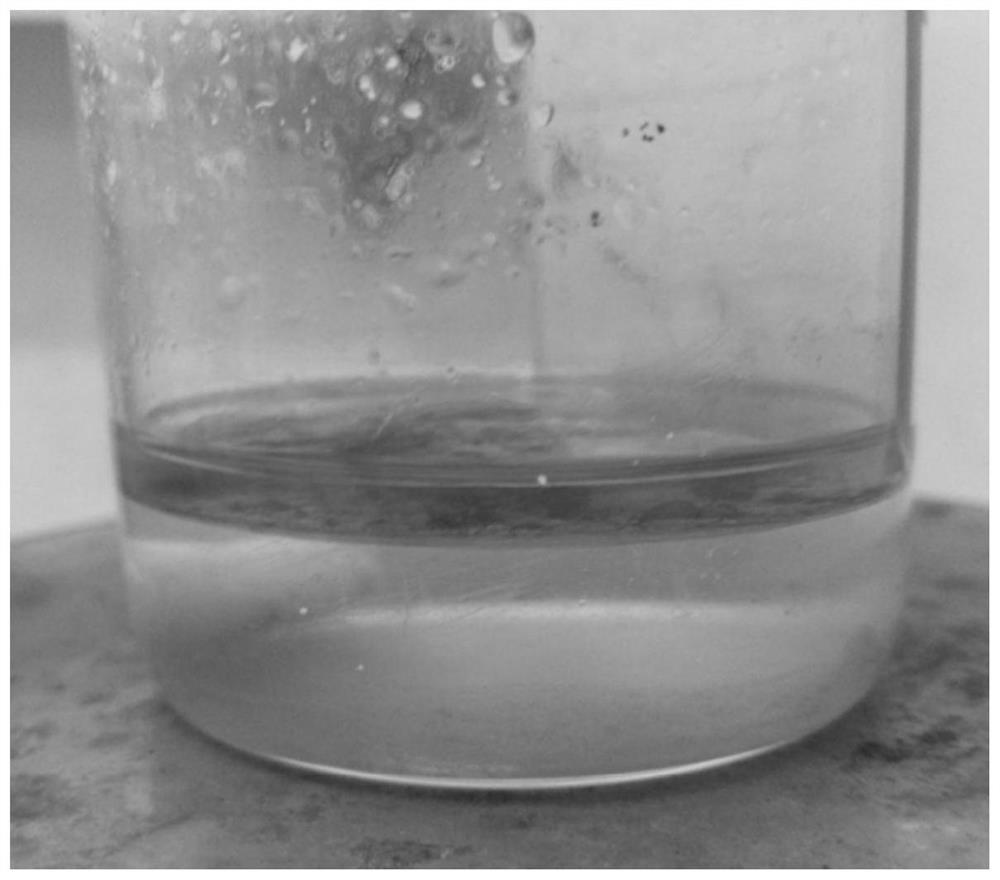

[0028] (2) Add 15 mL of n-hexane and 0.01 g of sodium oleate to the solution in step (1) while stirring, continue to stir and mix for a period of time, and let it stand still, and the liquid surface is clearly stratified;

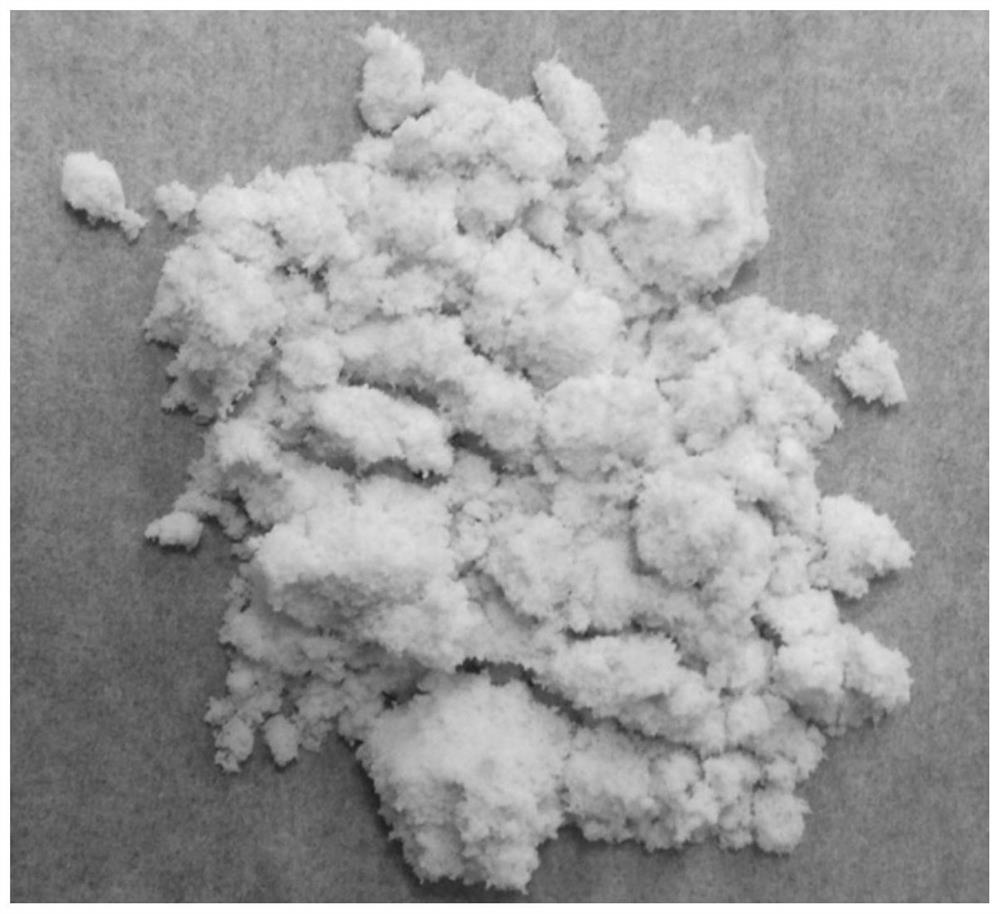

[0029] (3) Use a separatory funnel to separate the layered solution. The upper layer solution is centrifuged at 6000r / min for 8 minutes to separate and recover the black particulate carbon material. The remaining solution is evaporated at 50°C to recover the extractant; the lower layer solution is evaporated at 80°C for 4h to recrystallize. Recovery and purification of sodium sulfate.

[0030] This embodiment handles 5g H acid process sodium sulfate salt...

Embodiment 2

[0032] (1) Weigh 5g of sodium sulfate salt slag produced by the H acid process in a crucible, put it into a muffle furnace and roast for 2 hours at a temperature of 350°C; dissolve the roasted solids in 20mL of water and stir with a magnetic force Stir until the salt mud is completely dissolved;

[0033] (2) Add 10 mL of n-hexane and 0.01 g of sodium oleate to the solution in step (1) while stirring, continue to stir and mix for a period of time, and let it stand still, and the liquid surface is clearly stratified;

[0034] (3) Use a separatory funnel to separate the layered solution. The upper layer solution is centrifuged at 7000r / min for 6 minutes to separate and recover the black particulate carbon material. The remaining solution is evaporated at 80°C to recover the extractant; the lower layer solution is evaporated at 100°C for 3h to recrystallize. Recovery and purification of sodium sulfate.

[0035] This embodiment handles 5g H acid process sodium sulfate salt slag, h...

Embodiment 3

[0037] (1) Weigh 5g of the sodium sulfate salt slag produced by the H acid process in a crucible, put it into a muffle furnace and roast for 2 hours at a roasting temperature of 400°C; dissolve the roasted solids in 20mL of water and stir with a magnetic force Stir until the salt mud is completely dissolved;

[0038] (2) Add 10 mL of n-hexane and 0.01 g of sodium oleate to the solution in step (1) while stirring, continue to stir and mix for a period of time, and let it stand still, and the liquid surface is clearly stratified;

[0039] (3) Use a separatory funnel to separate the layered solution. The upper layer solution is centrifuged at 8000r / min for 5 minutes to separate and recover the black particulate carbon material. The remaining solution is evaporated at 100°C to recover the extractant; the lower layer solution is evaporated at 120°C for 2h to recrystallize. Recovery and purification of sodium sulfate.

[0040] This embodiment handles 5g H acid process sodium sulfat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com