Apparatus and method for increasing the oxygen content of metal powders by ozone oxidation

A technology of powder oxygen content and ozone oxidation, applied in metal processing equipment, transportation and packaging, etc., can solve problems such as deterioration of dispersibility, and achieve the effects of low production cost, good oxidation effect and simple process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

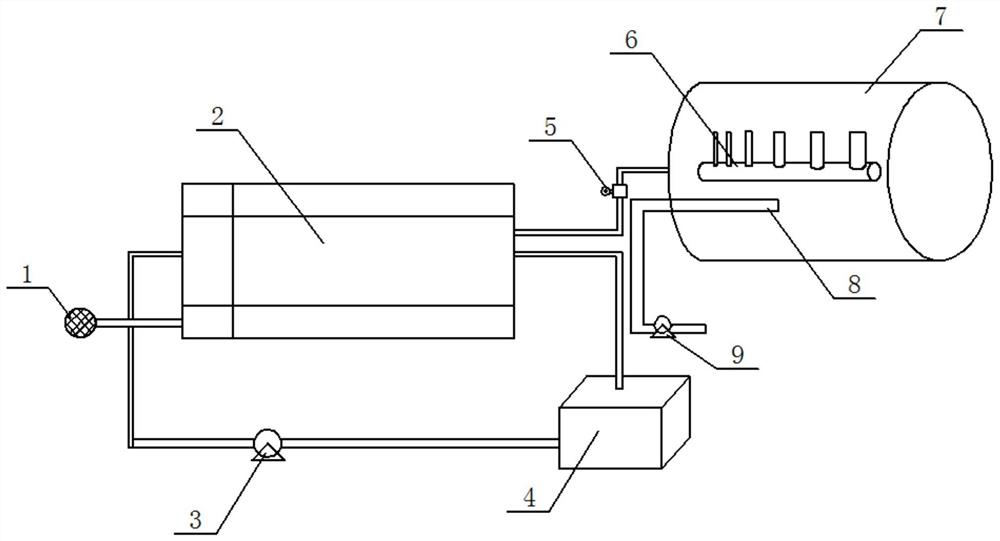

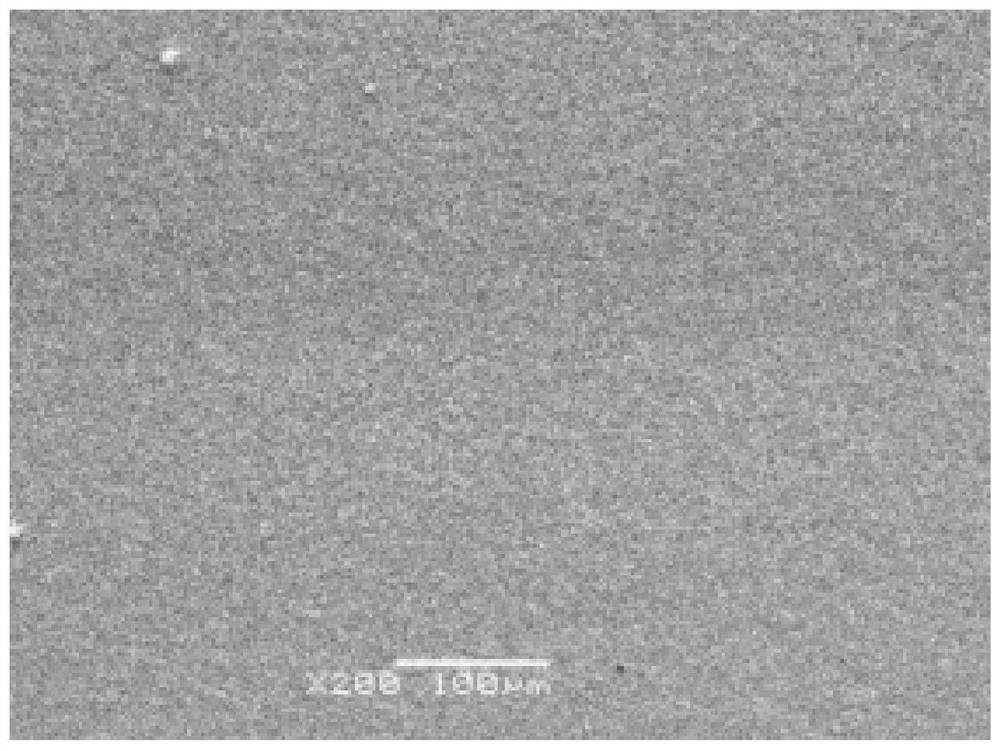

[0064] Adopt the treatment method that the ozone oxidation described in the present invention increases the oxygen content of metal powder to process nickel powder, concrete operation steps are as follows:

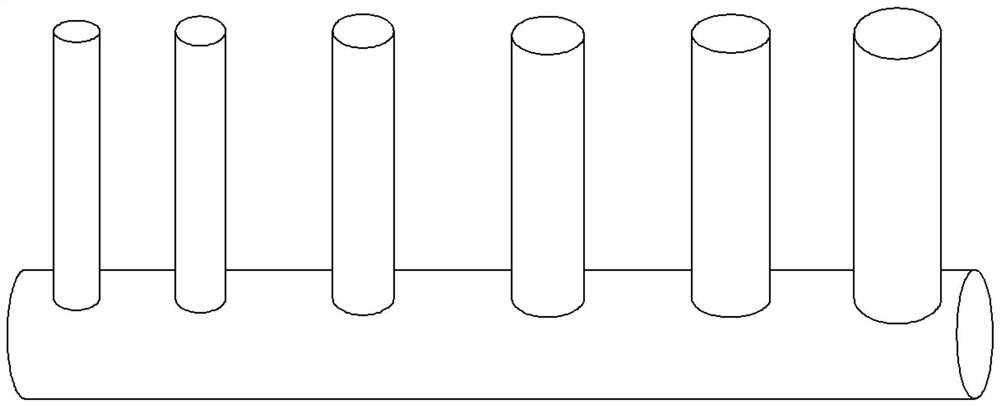

[0065] (1) Take metal nickel powder with an average particle size of 0.3-0.4um (micron) produced by PVD method, and place it in a rotatable and sealable stainless steel cylindrical barrel (oxygenation reactor) 50kg, the diameter of the stainless steel barrel 500mm, length about 1500mm, volume about 0.3m 3 , The barrel is equipped with an ozone dosing distributor and a porous filter tube.

[0066] (2) Turn on the circumferential rotation of the stainless steel cylinder barrel body, and rotate at a speed of 10 rpm (rev / min);

[0067] (3) And turn on the ozone generator (OZ-50 gram ozone tube) to generate an ozone concentration of 30g / m 3 , the gas source is air;

[0068] (4) Turn on the booster pump and adjust the air flow in step (3) to 2.2-2.5m 3 / h, the continuous int...

Embodiment 2

[0073] (1) Take metal nickel powder with an average particle size of 0.3-0.4um produced by the PVD method, and place it in a rotatable and sealable stainless steel cylindrical barrel of 50kg. The diameter of the stainless steel barrel is 500mm, the length is about 1500mm, and the volume is about 0.3 m 3 , the barrel is equipped with an ozone dosing distributor and a porous tube.

[0074] (2) Turn on the heating system for step (1), and heat the temperature in the stainless steel barrel at 50-110°C;

[0075] (3) Turn on the circumferential rotation of the barrel in step (1), and rotate at a speed of 10 rpm (rev / min);

[0076] (4) Open the ozone generator (OZ-50 gram ozone tube) to step (2), the ozone concentration that produces is 30g / m 3 , the gas source is air;

[0077] (5) Turn on the booster pump and adjust the air flow in step (3) to 2.2-2.5m 3 / h, the continuous intake time is about 3h;

[0078] (6) Stop steps (2), (3), (4), and (5), and take samples to measure the o...

Embodiment 3

[0082] (1) Take metal nickel powder with an average particle size of 0.3-0.4um produced by the PVD method, and place it in a rotatable and sealable stainless steel cylindrical barrel of 50kg. The diameter of the stainless steel barrel is 500mm, the length is about 1500mm, and the volume is about 0.3 m 3 , the barrel is equipped with an ozone dosing distributor and a porous tube.

[0083] (2) Turn on the circumferential rotation of the barrel in step (1), and rotate at a speed of 10 rpm (rev / min);

[0084](3) Open the ozone generator to step (2) (can adopt OZ-20 gram ozone tube OZ-50 gram ozone tube, OZ-100 gram ozone tube), produce ozone concentration and be 30g / m 3 , the gas source is air;

[0085] (4) Turn on the booster pump and adjust the air flow in step (3) to 0.8-6.0m 3 / h, the continuous intake time is about 3h;

[0086] (5) Stop steps (2), (3), and (4), and take samples to measure the oxygen content.

[0087] Table 6 is the same time, the ozone oxidation effect d...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com