a car seat

A technology for car seats and seats, which is applied in the direction of vehicle seats, seat heating/ventilation devices, vehicle parts, etc., and can solve the problem of heating elements without automatic constant temperature and power compensation functions, large thermal inertia, and low electrothermal conversion efficiency, etc. problem, to avoid the rapid rise of the seat temperature and achieve the effect of uniform temperature

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0048] This embodiment provides a car seat, which includes a seat body and a graphene electrothermal film for supplying heat to the seat body.

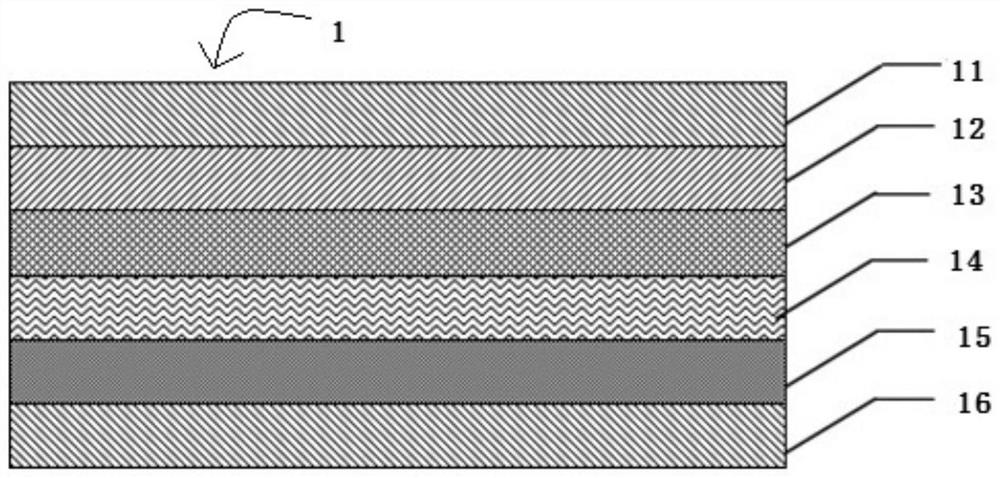

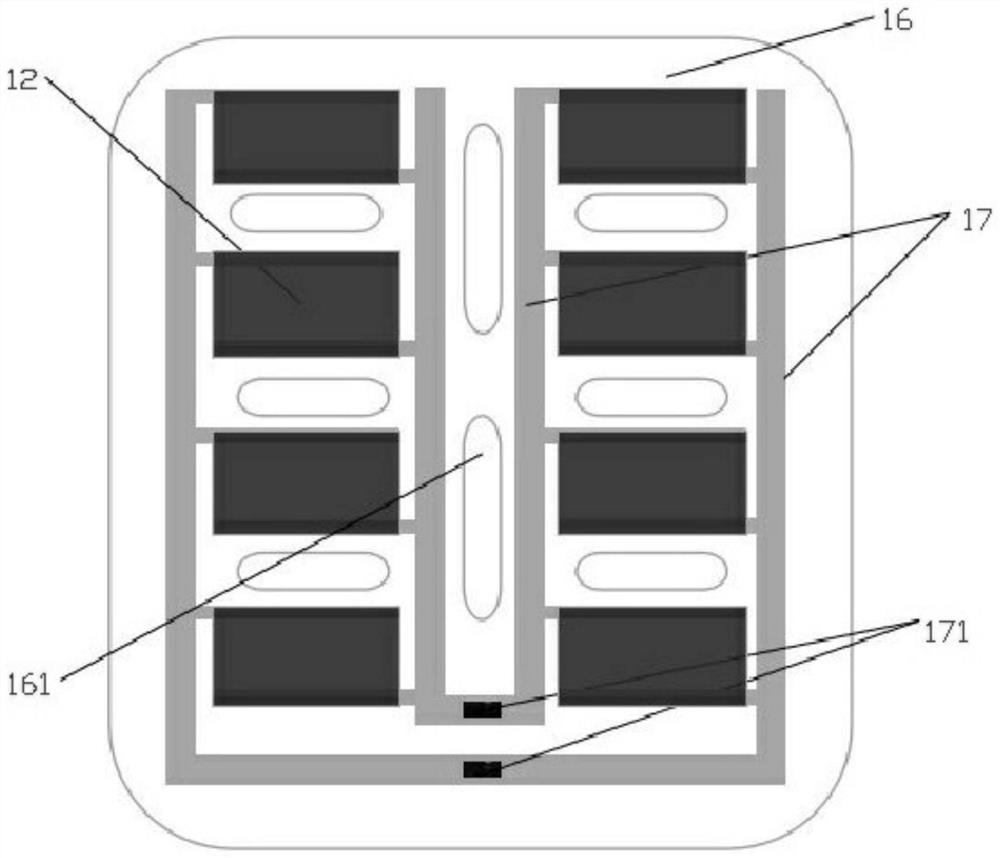

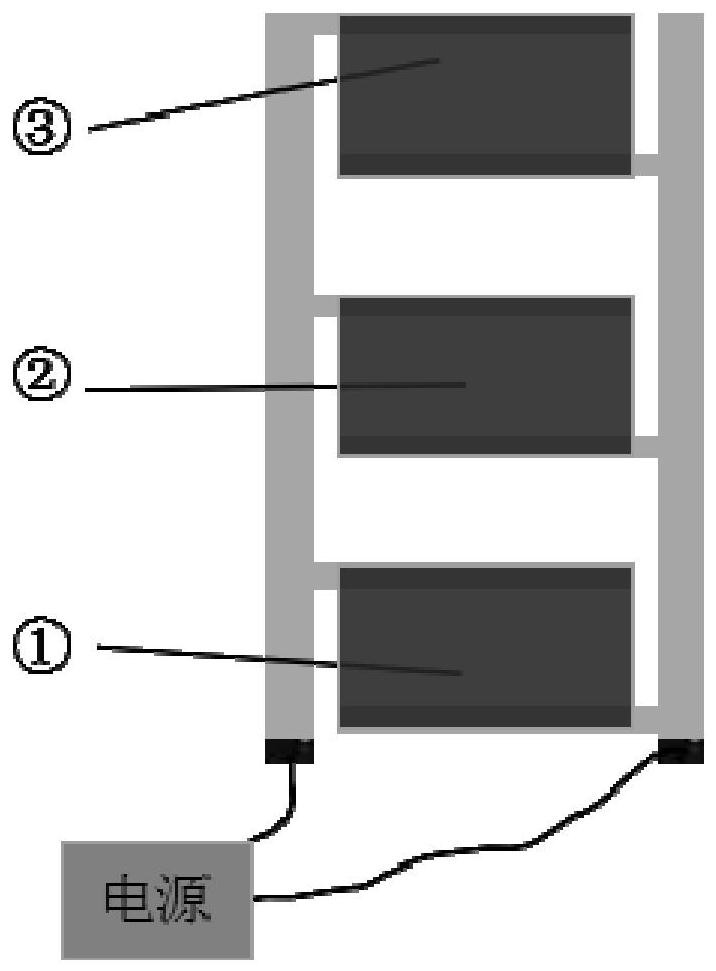

[0049] Such as Figure 1-2 As shown, the graphene electrothermal film 1 includes a first insulating protective layer 11, an intermediate layer and a second insulating protective layer 16 arranged from top to bottom, and the intermediate layer has a uniform distribution between the first insulating protective layer 11 and the second insulating protective layer 16. multiple between the two insulation protection layers 16;

[0050] Wherein, the intermediate layer includes a heat storage slow-release layer 12 , a graphene heating layer 13 , a conductor 14 and a heat reflection layer 15 arranged from top to bottom, and the conductor 14 is used to energize the graphene heating layer 13 . In this example, the heat generated by the graphene heating layer 13 passes through the first insulating protective layer 11 to the seat body and then hea...

Embodiment 2

[0069] This embodiment provides a car seat, and the difference from Embodiment 1 is:

[0070] The heat storage slow release layer is made of heat storage slow release slurry, its thickness is about 120 μm, in parts by mass, the heat storage slow release slurry contains white carbon black particles (thermal conductivity is about 27W·m -1 ·K -1 , the specific heat capacity is about 745J·K -1 ·Kg -1 ) 25 parts, 20 parts of water-based acrylic resin, 20 parts of water; additives: 0.5 part of potassium polyacrylate, 0.2 part of polysiloxane defoamer, 0.3 part of diethylethanolamine, 1 part of polyacrylic acid thickener . The heat storage slow-release slurry is prepared by the following method: weighing each raw material according to the formula, mixing white carbon black particles, water and water-based acrylic resin ester, and then adding polyacrylic acid potassium salt and polysiloxane defoaming Agent, diethylethanolamine and polyacrylic acid thickener are mixed to form a slu...

Embodiment 3

[0075] This embodiment provides a car seat, which differs from Embodiment 1 in that:

[0076] Specifically, the heat storage slow-release layer is made of heat storage slow-release slurry, the thickness of which is about 90 μm, in parts by mass, and the heat storage slow-release slurry contains zinc oxide particles (the thermal conductivity is about 29.98 W·m -1 ·K -1 , the specific heat capacity is about 490J·K -1 ·Kg -1 ) 28 parts, 22 parts of water-based polyurethane resin, 20 parts of water; additives: 0.5 part of potassium polyacrylate, 0.2 part of silicone defoamer, 0.3 part of diethylethanolamine, 1 part of polyacrylic acid thickener. The heat storage slow-release slurry is prepared by the following method: Weigh each raw material according to the formula, mix zinc oxide particles, water and water-based polyurethane resin, and then add polyacrylic acid potassium salt, organic silicon defoamer, diethyl Ethanolamine and polyacrylic acid thickener are mixed to form a slu...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thermal conductivity | aaaaa | aaaaa |

| thermal conductivity | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com