Novel magnetic ring device

A new type of magnetic ring technology, applied in the fields of magnetic field/electric field water/sewage treatment, water/sewage multi-stage treatment, flocculation/sedimentation water/sewage treatment, etc. load and other problems, to achieve the effect of improving the utilization rate of magnetic powder and equipment efficiency, and reducing the long-term operation of magnetic powder

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

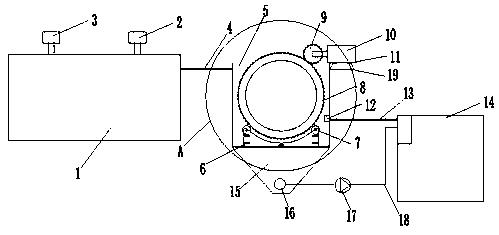

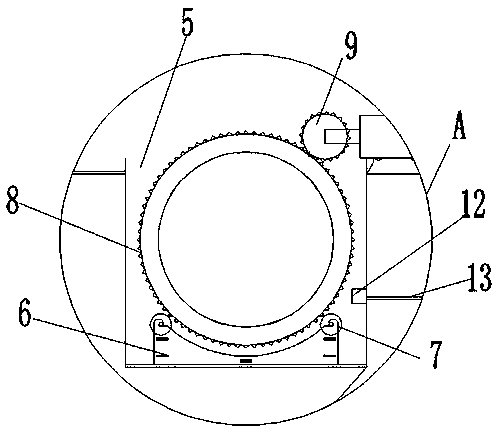

[0034] Please refer to Figure 1-2 , Embodiment 1 of the present invention is:

[0035] A new type of magnetic ring device, including a drum grille gear 8 arranged inside the magnetic adsorption pool 5, a support base 6 is provided below the drum grille gear 8, and the support base 6 is fixedly connected to the inner bottom wall of the magnetic adsorption pool 5 , one side of the upper end of the drum grid gear 8 is meshed with a transmission gear 9, and the transmission gear 9 is connected with a frequency conversion motor 10 through the rotating shaft;

[0036] One end of the first conveying pipe 4 is connected through the side wall of the magnetic adsorption tank 5, and the other end of the first conveying pipe 4 is connected through the coagulation tank 1, and the coagulation tank 1 is provided with a coagulant dosing mechanism 2 and a flocculation tank 1. Dosing mechanism 3;

[0037] The other side wall of the magnetic adsorption pool 5 is provided with a first mud outl...

Embodiment 2

[0040] Please refer to Figure 1-2 , the second embodiment of the present invention is:

[0041] A new magnetic ring device, on the basis of the first embodiment, also includes a sludge pump 17 on the third conveying pipe 18 .

Embodiment 3

[0043] Please refer to Figure 1-2 , Embodiment three of the present invention is:

[0044] A new magnetic ring device, on the basis of the second embodiment, also includes a bearing 7 on the upper end surface of the support base 6 .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com