Textile sewage purifying system

A sewage purification and hydraulic technology, applied in the textile field, to achieve the effect of fully removing impurities, improving the cleanliness of the effluent, and improving the supporting strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

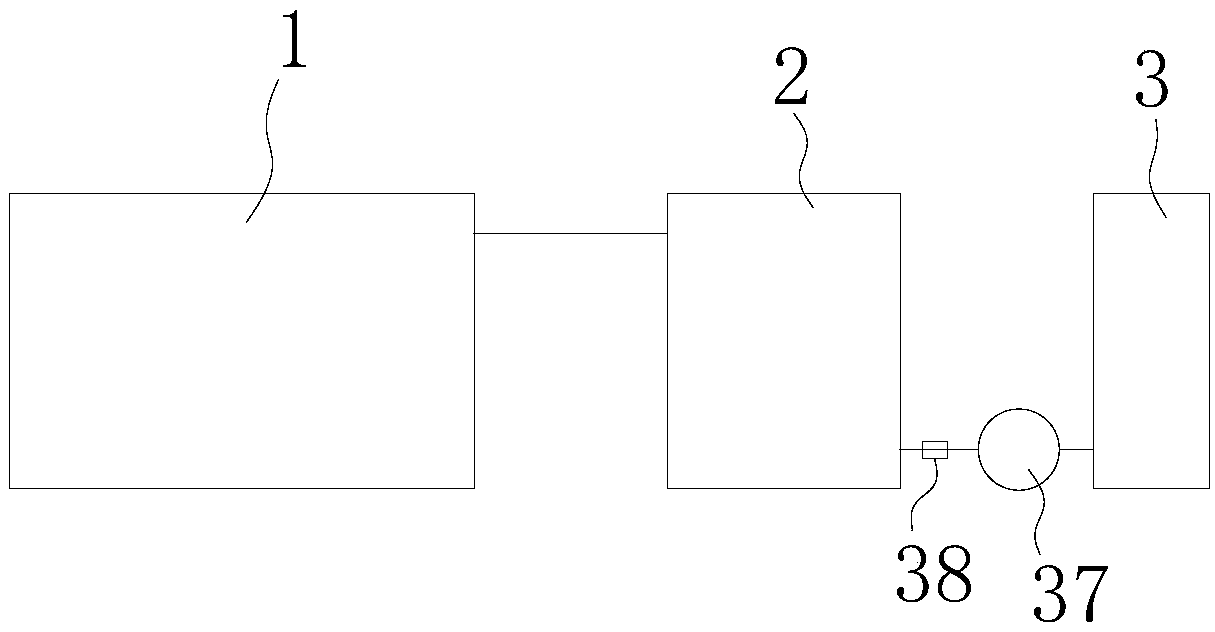

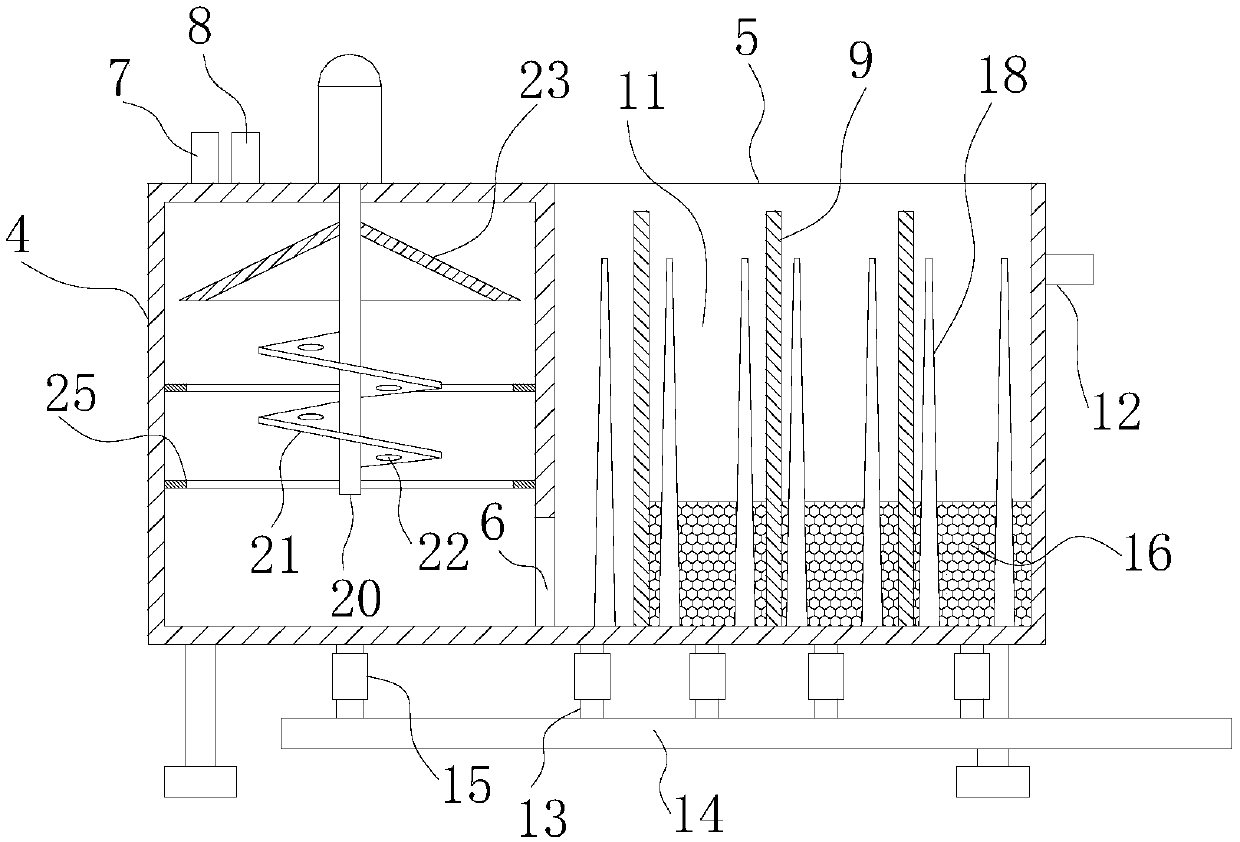

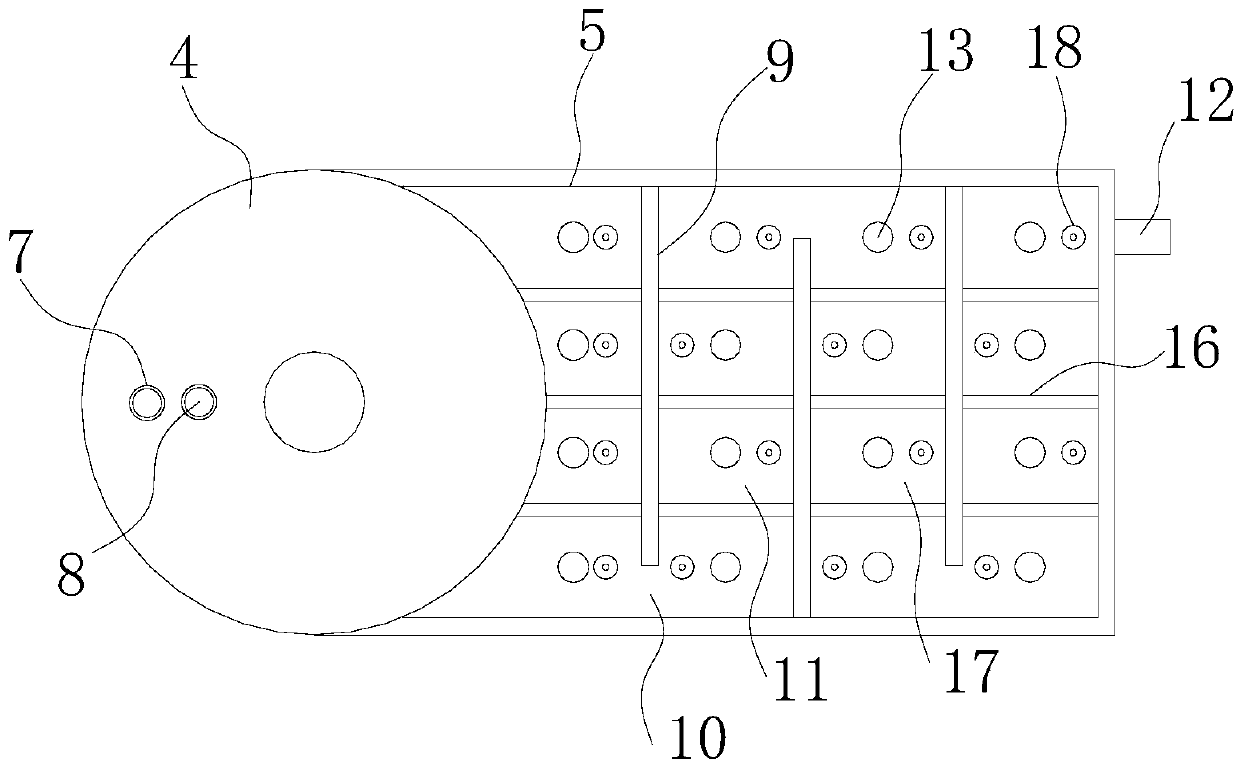

[0027] Such as Figure 1-10 The textile sewage purification system shown includes a flocculation and sedimentation device 1 , a biological contact oxidation device 2 and an activated carbon adsorption device 3 which are connected in sequence according to the sequence of wastewater treatment. The function of the flocculation and sedimentation device 1 is to perform flocculation and sedimentation treatment on the wastewater after adding the flocculation agent to the wastewater, so as to basically remove suspended solids and impurities in the wastewater. The flocculating agent such as: aluminum sulfate, aluminum chloride, ferric sulfate, ferric chloride, polyaluminum chloride, polyaluminum sulfate, polyferric chloride, polyferric sulfate, etc., the staff can carry out according to the specific type of textile wastewater Reasonable choice. The biological contact oxidation device 2 allows aerobic microorganisms to contact the water body, thereby degrading the residual organic matt...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com