Radiation-proof concrete capable of reducing secondary radiation and preparation method of concrete

A secondary radiation and radiation protection technology, applied in the field of construction, can solve problems such as the decline of shielding performance and affect the setting time, and achieve the effects of reducing secondary radiation, improving work performance and reducing slump.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

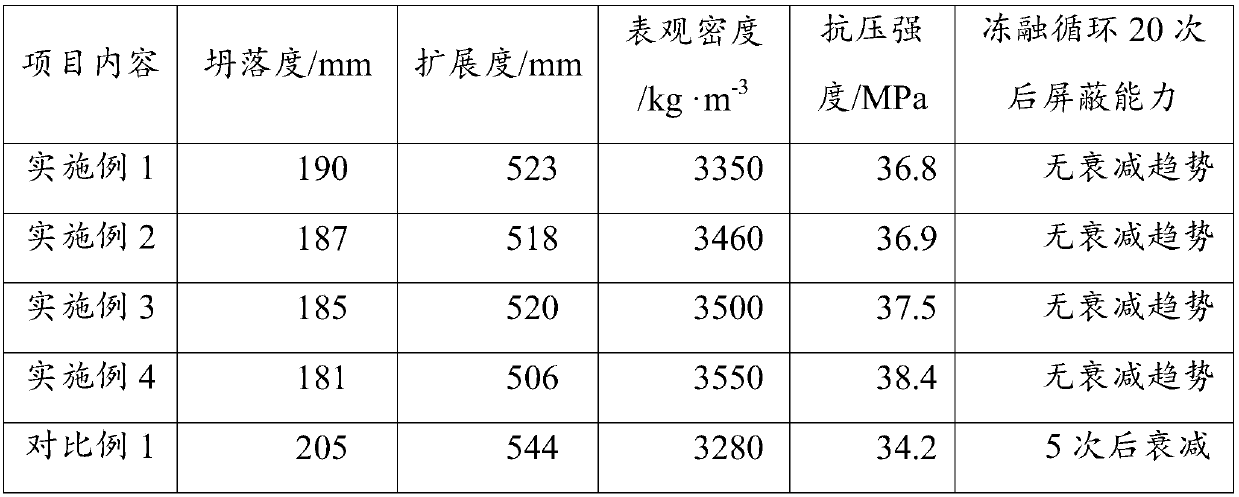

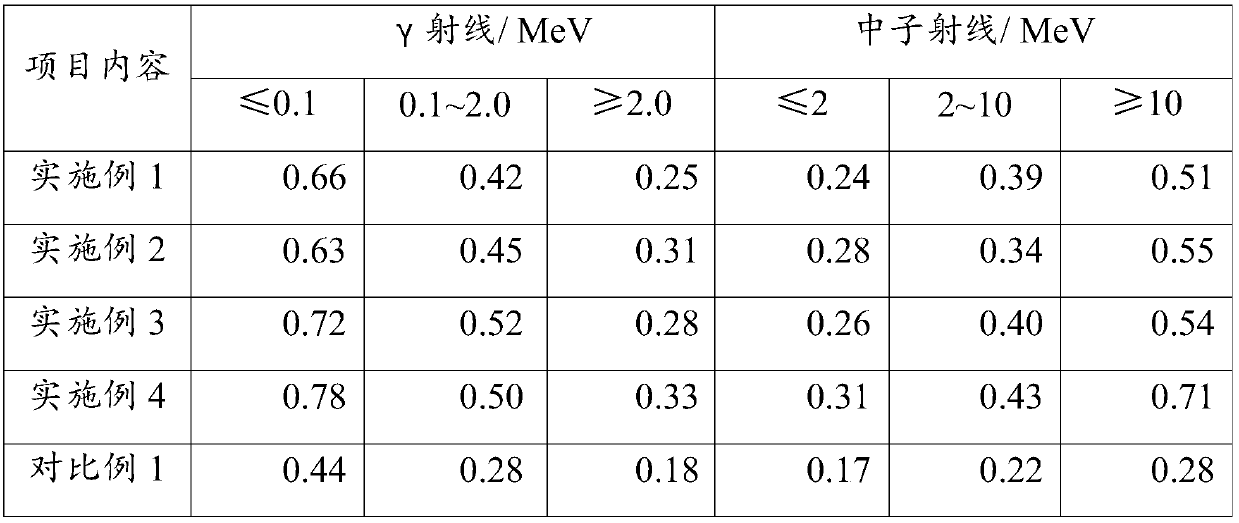

Examples

Embodiment 1

[0035] Radiation-resistant concrete product 1 is prepared by the following method:

[0036] (1) In parts by weight, weigh 100 parts of high alumina cement, 40 parts of borax, 50 parts of steel slag micropowder, 140 parts of slag micropowder, 10 parts of steel fiber, 2 parts of water reducer, 2 parts of early strength agent and 8 parts of retarder Parts, add to the stirring tank for pre-mixing and stirring to obtain the mixture;

[0037](2) Then add 500 parts of barite and 80 parts of alumina ceramics into the stirring tank, fully mix and stir in the stirring tank, add water while stirring, add water to a total of 100 parts, control the stirring time of the whole feeding process to 30-60s ;

[0038] (3) Inject the slurry obtained in the previous step into a mold, and use heat preservation and moisturizing curing, and the watering and curing time must not be less than 14 days (to avoid the temperature difference between the inside and outside of the concrete), and the radiation...

Embodiment 2

[0040] Radiation-resistant concrete product 2 is prepared by the following method:

[0041] (1) In parts by weight, weigh 200 parts of high alumina cement, 15 parts of borax, 120 parts of steel slag powder, 70 parts of slag powder, 30 parts of steel fiber, 8 parts of water reducing agent, 2 parts of early strength agent and 2 parts of retarder. Parts, add to the stirring tank for pre-mixing and stirring to obtain the mixture;

[0042] (2) Then add 700 parts of barite and 160 parts of alumina ceramics into the stirring tank, fully mix and stir in the stirring tank, add water while stirring, add water to a total of 200 parts, control the stirring time of the whole feeding process to 30-60s ;

[0043] (3) Inject the slurry obtained in the previous step into a mold, and use heat preservation and moisturizing curing, and the watering and curing time must not be less than 14 days (to avoid the temperature difference between the inside and outside of the concrete), and the radiation...

Embodiment 3

[0045] Radiation-resistant concrete product 3 is prepared by the following method:

[0046] (1) In parts by weight, weigh 150 parts of high alumina cement, 30 parts of borax, 100 parts of steel slag micropowder, 100 parts of slag micropowder, 10 parts of steel fiber, 6 parts of water reducer, 8 parts of early strength agent and 2 parts of retarder Parts, add to the stirring tank for pre-mixing and stirring to obtain the mixture;

[0047] (2) Then add 600 parts of barite and 130 parts of alumina ceramics into the stirring tank, fully mix and stir in the stirring tank, add water while stirring, add water to a total of 200 parts, control the stirring time of the whole feeding process to 30-60s ;

[0048] (3) Inject the slurry obtained in the previous step into a mold, and use heat preservation and moisturizing curing, and the watering and curing time must not be less than 14 days (to avoid the temperature difference between the inside and outside of the concrete), and the radiat...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Apparent density | aaaaa | aaaaa |

| Apparent density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com