Polylactic acid chain extender, preparation method thereof and modified polylactic acid

A polylactic acid and chain extender technology, applied in the field of modified polylactic acid, can solve the problems of slow dispersion speed, uneven dispersion, uneven molecular weight distribution, etc., and achieve cleanliness, good compatibility, and easy control of product quality Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0025] 1) The formula of the polylactic acid chain extender is (by mass parts):

[0026] Polylactic acid (2003D, NatureWorks, USA): 100;

[0027] Glycidyl methacrylate: 10;

[0028] Antioxidant 1010: 0.2;

[0029] 2) Preparation process of polylactic acid chain extender

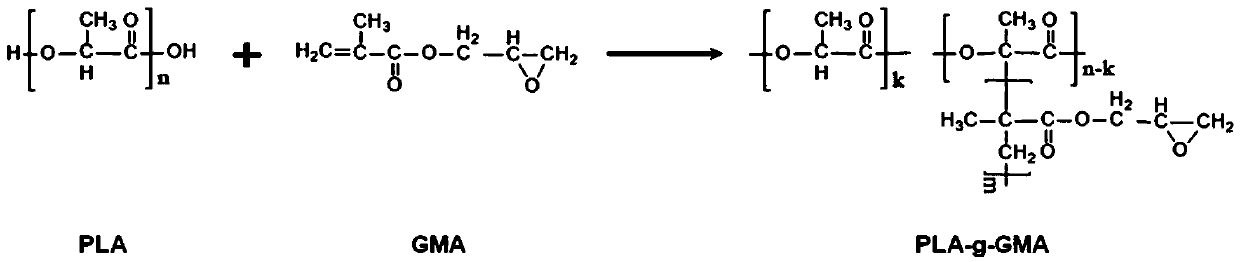

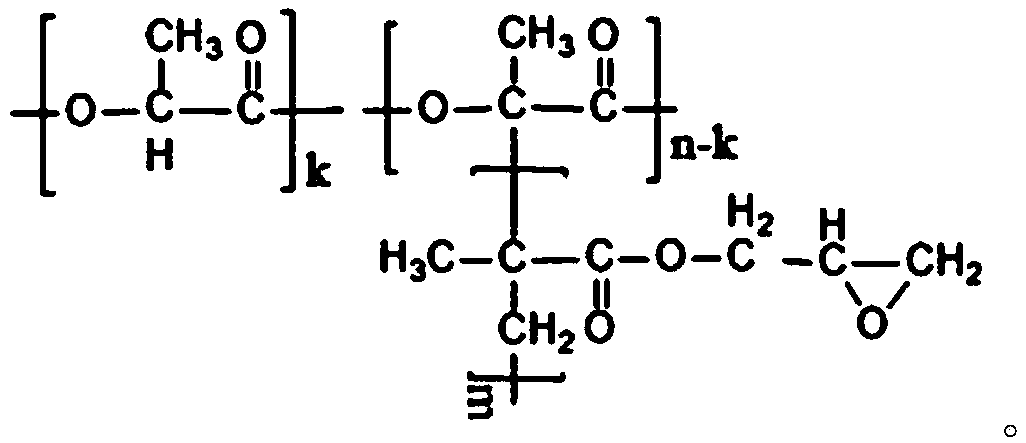

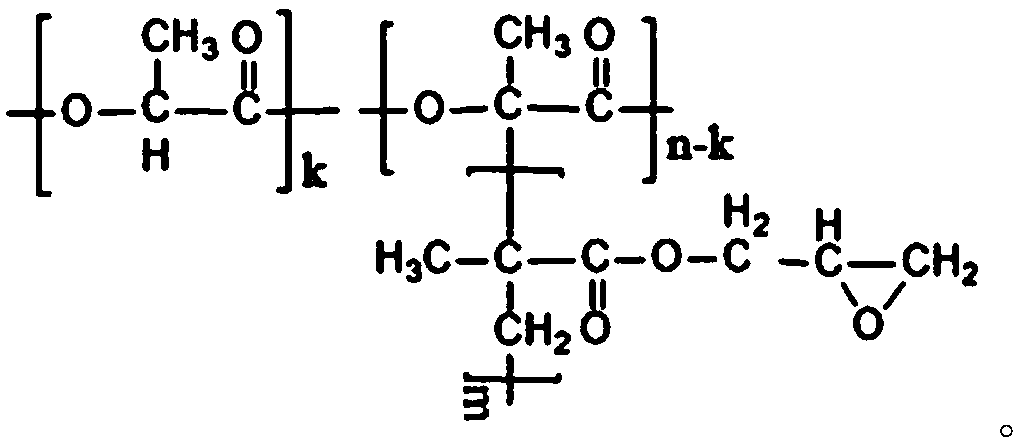

[0030] First dry the polylactic acid in a dryer at 80°C for 10 hours, then add the polylactic acid, glycidyl methacrylate and antioxidant 1010 into the high-speed mixer according to the above mass fractions and mix evenly. Extrude and granulate. Finally, the particle is irradiated with an absorbed dose of 20kGy electron beams to prepare the polylactic acid chain extender-glycidyl methacrylate grafted polylactic acid copolymer (PLA-g-GMA) of the present invention, and its preparation reaction schematic diagram is shown in the attached figure 1 .

Embodiment 2

[0032] 1) The formula of the polylactic acid chain extender is (by mass parts):

[0033] Polylactic acid (2003D, NatureWorks, USA): 100;

[0034] Glycidyl methacrylate: 1;

[0035] Antioxidant 1010: 0.1;

[0036] 2) Preparation process of polylactic acid chain extender

[0037] First dry the polylactic acid in a dryer at 80°C for 10 hours, then add the polylactic acid, glycidyl methacrylate and antioxidant 1010 into the high-speed mixer according to the above mass fractions and mix evenly. Extrude and granulate. Finally, the particles are irradiated with electron beams with an absorbed dose of 10 kGy to prepare the polylactic acid chain extender-glycidyl methacrylate grafted polylactic acid copolymer (PLA-g-GMA) of the present invention.

Embodiment 3

[0039] 1) The formula of the polylactic acid chain extender is (by mass parts):

[0040] Polylactic acid (2003D, NatureWorks, USA): 100;

[0041] Glycidyl methacrylate: 30;

[0042] Antioxidant 1010: 0.5;

[0043] 2) Preparation process of polylactic acid chain extender

[0044] First dry the polylactic acid in a dryer at 80°C for 10 hours, then add the polylactic acid, glycidyl methacrylate and antioxidant 1010 into the high-speed mixer according to the above mass fractions and mix evenly. Extrude and granulate. Finally, the particles are irradiated with electron beams with an absorbed dose of 30 kGy to prepare the polylactic acid chain extender-glycidyl methacrylate grafted polylactic acid copolymer (PLA-g-GMA) of the present invention.

[0045] performance test

[0046] The effect of chain extender on polylactic acid was compared by torque rheometer.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com