Gel ink and ballpoint pens containing it

A neutral ink and mixture technology, applied in ink, household appliances, applications, etc., can solve the problems of damage to the writing performance of neutral pens, lack of anti-leakage neutral ink, damage to the fluency of ink discharge, etc., and achieve excellent anti-leakage. performance, not easily deformed, the effect of excellent low temperature writing performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0053] thickening intermediate preparation

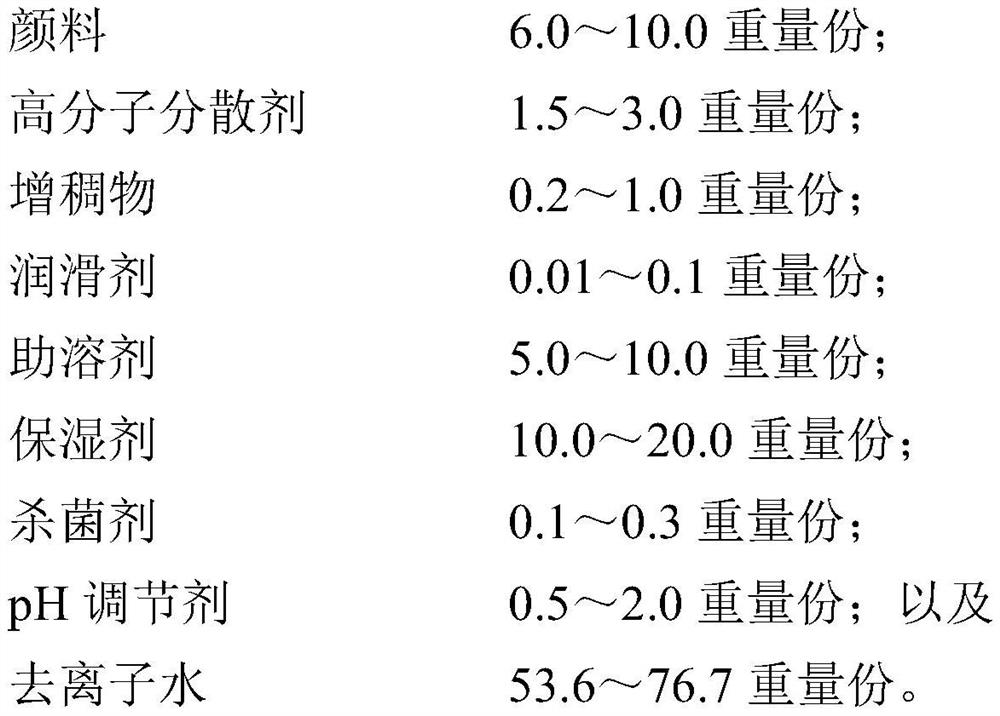

[0054] Add 0.7 parts of triethanolamine to 25 parts of deionized water under stirring, and then add 0.45 parts of acrylic thickener HS1152 and 0.15 parts of polyethylene glycol POLYOX WSR N-80 (number average molecular weight: 200,000). The molecular chain segment of the thickener is gradually opened, the viscosity of the system increases, and the stirring speed is gradually increased until the system is uniformly mixed to obtain a thickening intermediate.

[0055] Color paste preparation

[0056] Add 5.0 parts of 1,3-butanediol and 4.5 parts of polymer dispersant Disperbyk-2012 (40% effective concentration) into 24.0 parts of deionized water, stir evenly, then add 8.0 parts of medium pigment carbon black Orilonte Black 5 After the addition, continue to stir for 2 hours to fully wet the carbon black, transfer the above mixture to a horizontal sand mill filled with 0.3mm diameter zirconium beads, and start circulating grinding. Duri...

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strain | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com