High-viscosity two-component epoxy paint

An epoxy coating, two-component technology, applied in the field of construction engineering, can solve the problems of low tensile bond strength, poor fatigue resistance, high crosslinking density, etc., and achieve good tensile bond strength, good alkali resistance, good adhesive effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

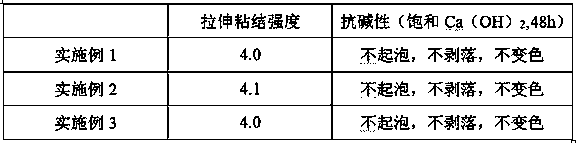

Examples

Embodiment 1

[0020] High-viscosity two-component epoxy coating, consisting of two components A and B:

[0021] Component A is composed of the following raw materials in parts by weight: 60 parts of E-42 epoxy resin, 10 parts of butyl benzyl glycidyl ether, 10 parts of n-butyl glycidyl ether, 30 parts of heavy calcium carbonate, talcum powder 50 parts, 1 part of triethylenediamine, 2.5 parts of nitrile rubber, 0.5 parts of Deqian 904s, 0.2 parts of Deqian 6801;

[0022] Component B is composed of the following raw materials in parts by weight: 30 parts of polyamide, 30 parts of talc, 10 parts of n-butyl glycidyl ether, 1 part of methyldiethanolamine, 0.2 part of Deqian 904s, 0.1 part of Deqian 6801 ;

[0023] The weight ratio of component A to component B is 1:1.

[0024] The preparation method of high-viscosity two-component epoxy paint is characterized in that:

[0025] The preparation method of component A is: E-42 epoxy resin, butyl benzyl glycidyl ether, n-butyl glycidyl ether, and ...

Embodiment 2

[0029] High-viscosity two-component epoxy coating, consisting of two components A and B:

[0030] Component A is composed of the following raw materials in parts by weight: 65 parts of E-42 epoxy resin, 20 parts of butyl benzyl glycidyl ether, 15 parts of n-butyl glycidyl ether, 40 parts of heavy calcium carbonate, talcum powder 60 parts, 5 parts of triethylenediamine, 5 parts of nitrile rubber, 0.8 parts of Deqian 904s, 0.5 parts of Deqian 6801;

[0031] Component B consists of the following raw materials in parts by weight: 40 parts of polyamide, 40 parts of talcum powder, 20 parts of n-butyl glycidyl ether, 3 parts of methyldiethanolamine, 0.4 parts of Deqian 904s, 0.3 parts of Deqian 6801 ;

[0032] The weight ratio of component A to component B is 1:1.

[0033] The preparation method of high-viscosity two-component epoxy paint is characterized in that:

[0034] The preparation method of component A is: E-42 epoxy resin, butyl benzyl glycidyl ether, n-butyl glycidyl eth...

Embodiment 3

[0038] High-viscosity two-component epoxy coating, consisting of two components A and B:

[0039] Component A is composed of the following raw materials in parts by weight: 62 parts of E-42 epoxy resin, 15 parts of butyl benzyl glycidyl ether, 13 parts of n-butyl glycidyl ether, 35 parts of heavy calcium carbonate, talcum powder 55 parts, 3 parts of triethylenediamine, 3.75 parts of nitrile rubber, 0.65 parts of Deqian 904s, 0.35 parts of Deqian 6801;

[0040] Component B is composed of the following raw materials in parts by weight: 35 parts of polyamide, 35 parts of talcum powder, 15 parts of n-butyl glycidyl ether, 2 parts of methyldiethanolamine, 0.3 parts of Deqian 904s, 0.2 parts of Deqian 6801 ;

[0041] The weight ratio of component A to component B is 1:1.

[0042] The preparation method of high-viscosity two-component epoxy paint is characterized in that:

[0043] The preparation method of component A is: E-42 epoxy resin, butyl benzyl glycidyl ether, n-butyl glyc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com