A special flexible transparent optical adhesive for nano-silver wire transparent conductive film and preparation method thereof

A technology of transparent conductive film and nano-silver wire, which is applied in the equipment, nanotechnology, nanotechnology and other directions for manufacturing conductive/semi-conductive layers, which can solve the problem of poor flexibility, poor matching of nano-silver wires, and overall device flexibility limitation, etc. problem, to achieve the effects of excellent aging resistance, no yellowing in weather resistance, and weak interaction force

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

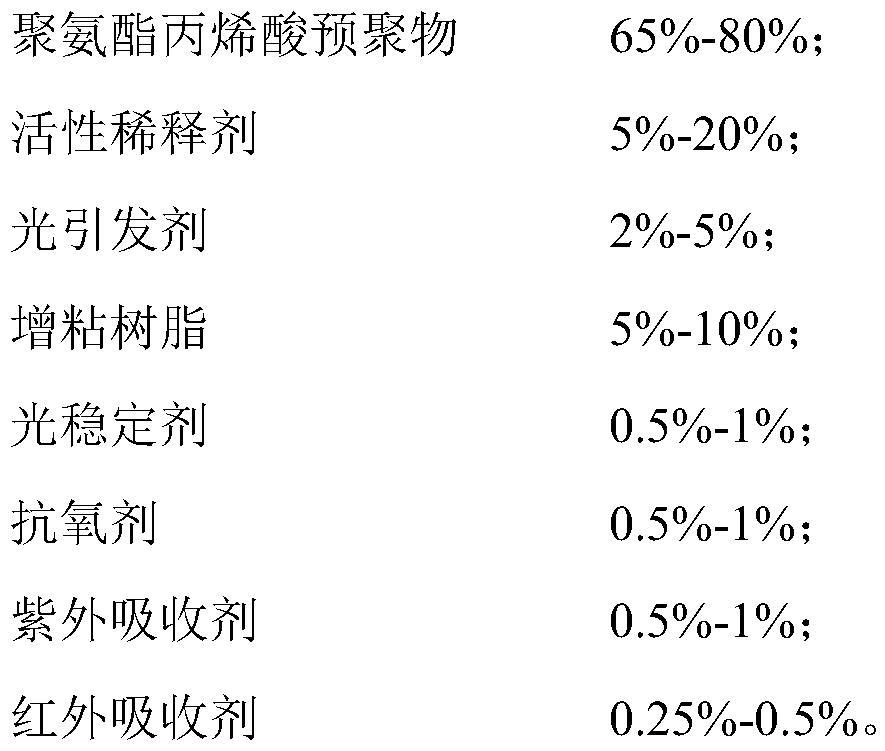

Method used

Image

Examples

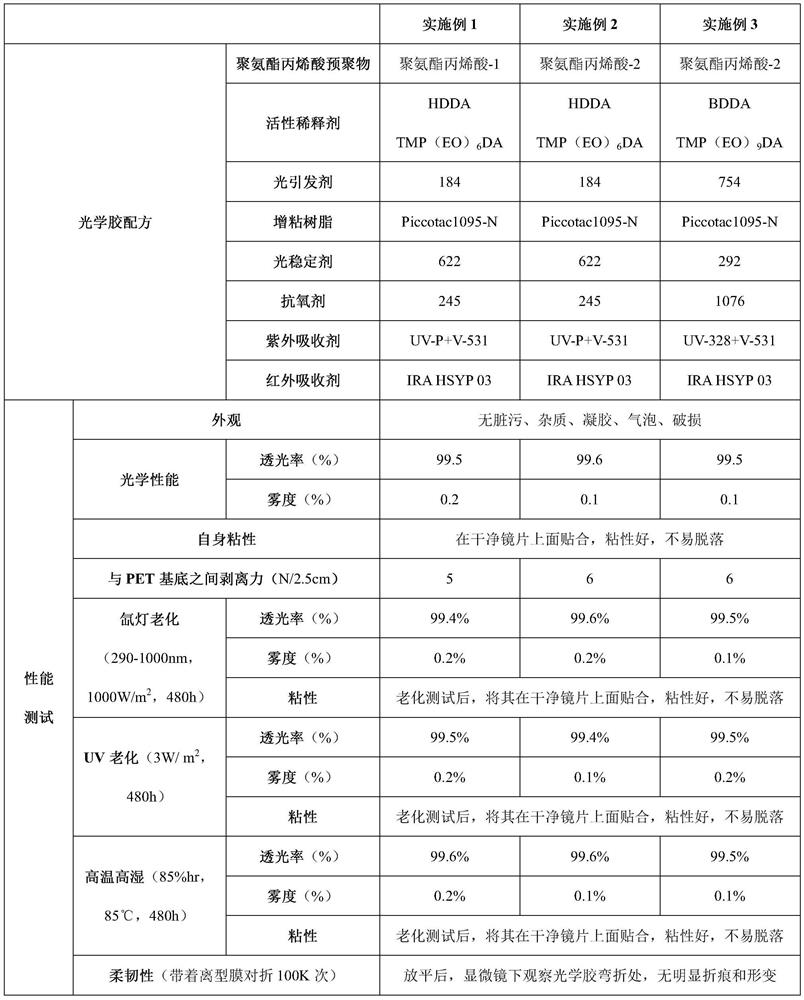

Embodiment 1

[0039] First, the synthesis of polyurethane acrylic acid prepolymer specifically includes the following steps:

[0040] (a) Dehydration of raw materials: PEG-400, polyoxypropylene triol-600, 1,6-hexamethylene diisocyanate and hydroxyethyl acrylate are subjected to high-temperature vacuum dehydration treatment. The treatment conditions are: temperature 80°C, vacuum Degree 0.06-0.08MPa, time 3h.

[0041] (b) Reaction of polyol and isocyanate: in N 2 Under a protective environment, add 6.05 mol of the above-mentioned dehydrated 1,6-hexamethylene diisocyanate into the flask, mechanically stir at a speed of 500 r / min, while slowly heating to 60°C, and then add the dehydrated 4 mol PEG The mixed solution of -400 and 1mol polyoxypropylene triol -600 was added dropwise into the flask at a constant speed for 2 hours; after the dropwise addition was completed, the reaction was continued with insulation and stirring, and the -NCO value was titrated every 0.5 hours until the -NCO content...

Embodiment 2

[0047] First, the synthesis of polyurethane acrylic acid prepolymer specifically includes the following steps:

[0048] (a) Dehydration of raw materials: PPG-400, polyoxypropylene triol-600, 1,6-hexamethylene diisocyanate and hydroxyethyl acrylate are subjected to high-temperature vacuum dehydration treatment. The treatment conditions are: temperature 80°C, vacuum Degree 0.06-0.08MPa, time 3h.

[0049] (b) Reaction of polyol and isocyanate: in N 2 Under a protective environment, add 7.15 mol of the above-mentioned dehydrated 1,6-hexamethylene diisocyanate into the flask, mechanically stir at a speed of 500 r / min, while slowly heating to 60°C, and then put the dehydrated 5 mol of PPG The mixed solution of -400 and 1mol polyoxypropylene triol -600 was added dropwise into the flask at a constant speed for 2 hours; after the dropwise addition was completed, the reaction was continued with insulation and stirring, and the -NCO value was titrated every 0.5 hours until the -NCO cont...

Embodiment 3

[0055] First, the synthesis of polyurethane acrylic acid prepolymer specifically includes the following steps:

[0056] (a) Dehydration of raw materials: PPG-400, polyoxypropylene triol-600, 1,6-hexamethylene diisocyanate and hydroxyethyl acrylate are subjected to high-temperature vacuum dehydration treatment. The treatment conditions are: temperature 80°C, vacuum Degree 0.06-0.08MPa, time 3h.

[0057] (b) Reaction of polyol and isocyanate: in N 2 Under a protective environment, add 7.15 mol of the above-mentioned dehydrated 1,6-hexamethylene diisocyanate into the flask, mechanically stir at a speed of 500 r / min, while slowly heating to 60°C, and then put the dehydrated 5 mol of PPG The mixed solution of -400 and 1mol polyoxypropylene triol -600 was added dropwise into the flask at a constant speed for 2 hours; after the dropwise addition was completed, the reaction was continued with insulation and stirring, and the -NCO value was titrated every 0.5 hours until the -NCO cont...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| transmittivity | aaaaa | aaaaa |

| haze | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com