Buffer coating for transferring silver nanowire conducting layer and transfer method thereof

A technology of nano-silver wire and buffer coating, applied in the direction of equipment for manufacturing conductive/semiconductive layers, nanotechnology for materials and surface science, conductive layers on insulating carriers, etc., can solve the problem of limiting the flexibility of conductive films In order to achieve the effects of moderate surface tension, good optical performance and good flexibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0066] In this example, the special flexible transparent optical adhesive for nano-silver wire transparent conductive film is prepared as follows:

[0067] First, the synthesis of polyurethane acrylic acid prepolymer specifically includes the following steps:

[0068] (a) Dehydration of raw materials: PEG-1000, polyether triol polyoxypropylene triol-600, 1,6-hexamethylene diisocyanate and hydroxyethyl acrylate are subjected to high-temperature vacuum dehydration treatment. The treatment conditions are: The temperature is 100°C, the vacuum degree is 0.1MPa, and the time is 2h.

[0069] (b) Reaction of polyol and isocyanate: in N 2 Under a protective environment, add 5.5 mol of the above-mentioned dehydrated 1,6-hexamethylene diisocyanate into the flask, mechanically stir at a speed of 500 r / min, while slowly heating to 60°C, and then add 3.64 mol of the dehydrated The mixed solution of PEG-1000 and 0.91mol polyether trihydric alcohol polyoxypropylene triol-600 was added dropw...

Embodiment 2

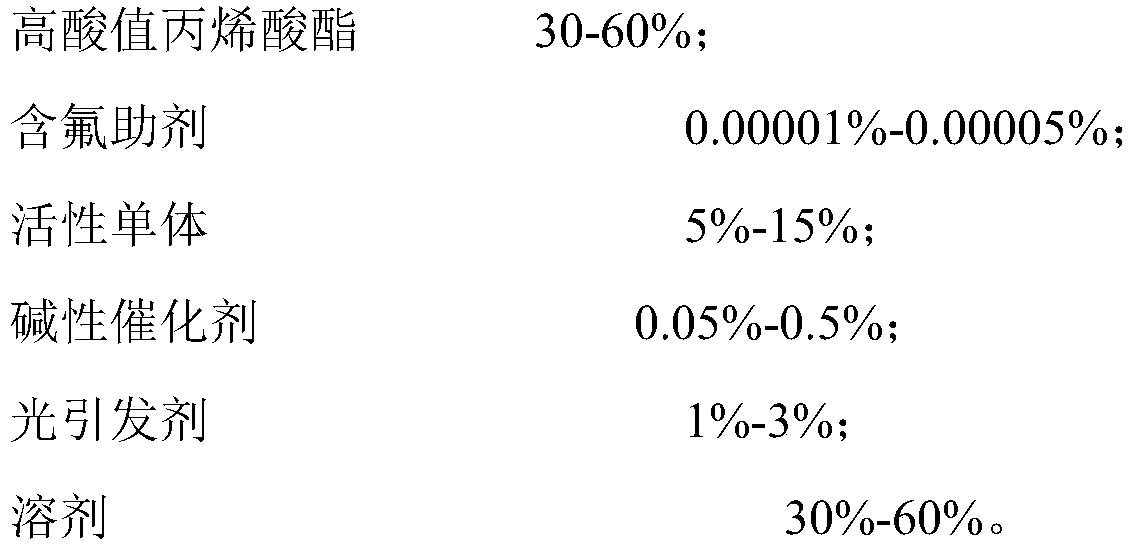

[0076] The composition of each component of the buffer coating in this embodiment by mass percentage is:

[0077]

[0078] Specifically, the high acid value acrylate used in this example is Doublemer270 (acid value 200-250, double bond chemical industry), the fluorine-containing additive used is FB9474 (Shanghai Fengbiao Chemical Technology Co., Ltd.), and the active monomer used is propylene glycol di Glycidyl ether, the basic catalyst used is triphenylphosphine, the photoinitiator used is photoinitiator BDK, and the solvent used is composed of ethyl acetate, isobutanol and cyclohexanol in a mass ratio of 1:1:1.

[0079] Based on the above-mentioned buffer coating, a base film with a buffer coating is produced in this embodiment, comprising the following steps:

[0080] (1) Add solvent, high acid value acrylate, fluorine-containing additives, active monomer, basic catalyst, and photoinitiator into the dispersion tank in sequence, mechanically stir at 1000r / min for 30min, a...

Embodiment 3

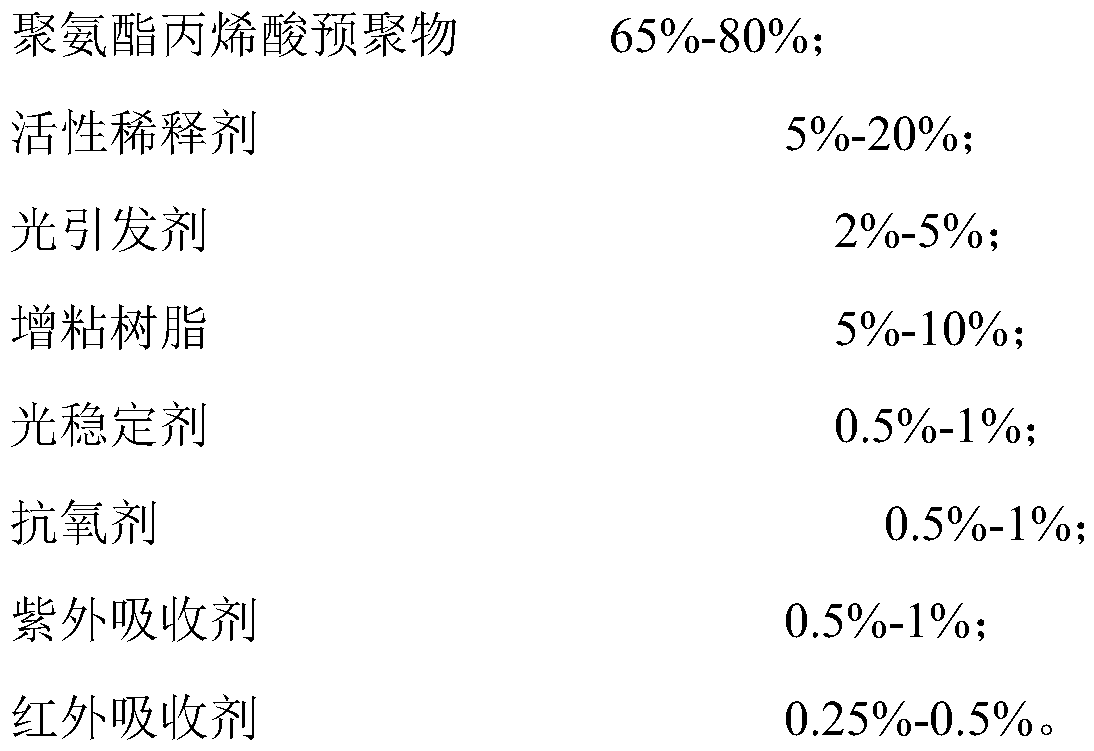

[0087] The composition of each component of the buffer coating in this embodiment by mass percentage is:

[0088]

[0089] Specifically, the high acid value acrylate used in this example is Doublemer623 (acid value 50-70, double bond chemical industry), the fluorine-containing additive used is FB9474 (Shanghai Fengbiao Chemical Technology Co., Ltd.), and the active monomer used is propylene glycol di Glycidyl ether, the basic catalyst used is triphenylphosphine, the photoinitiator used is photoinitiator BDK, and the solvent used is composed of ethyl acetate, isobutanol and cyclohexanol in a mass ratio of 1:1:1.

[0090] Based on the above-mentioned buffer coating, a base film with a buffer coating is produced in this embodiment, comprising the following steps:

[0091] (1) Add solvent, high acid value acrylate, fluorine-containing additives, active monomer, basic catalyst, and photoinitiator into the dispersion tank in sequence, mechanically stir at 1000r / min for 30min, and...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com