Rivet pressing water pipe connector with sealing performance for battery box water cooling plate

A technology of water pipe joints and water cooling plates, which is applied in the direction of pipes/pipe joints/pipe fittings, secondary batteries, pipes, etc. It can solve the problem of unreliable sealing of sealing and fastening interfaces, affecting the cooling effect of the water cooling system, failure of electronic components in battery packs, etc. Problems, achieve the effect of excellent structural strength and corrosion resistance, overcome the difficulty of repair, and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] The following are specific embodiments of the present invention and the accompanying drawings to further describe the technical solutions of the present invention, but the present invention is not limited to these embodiments.

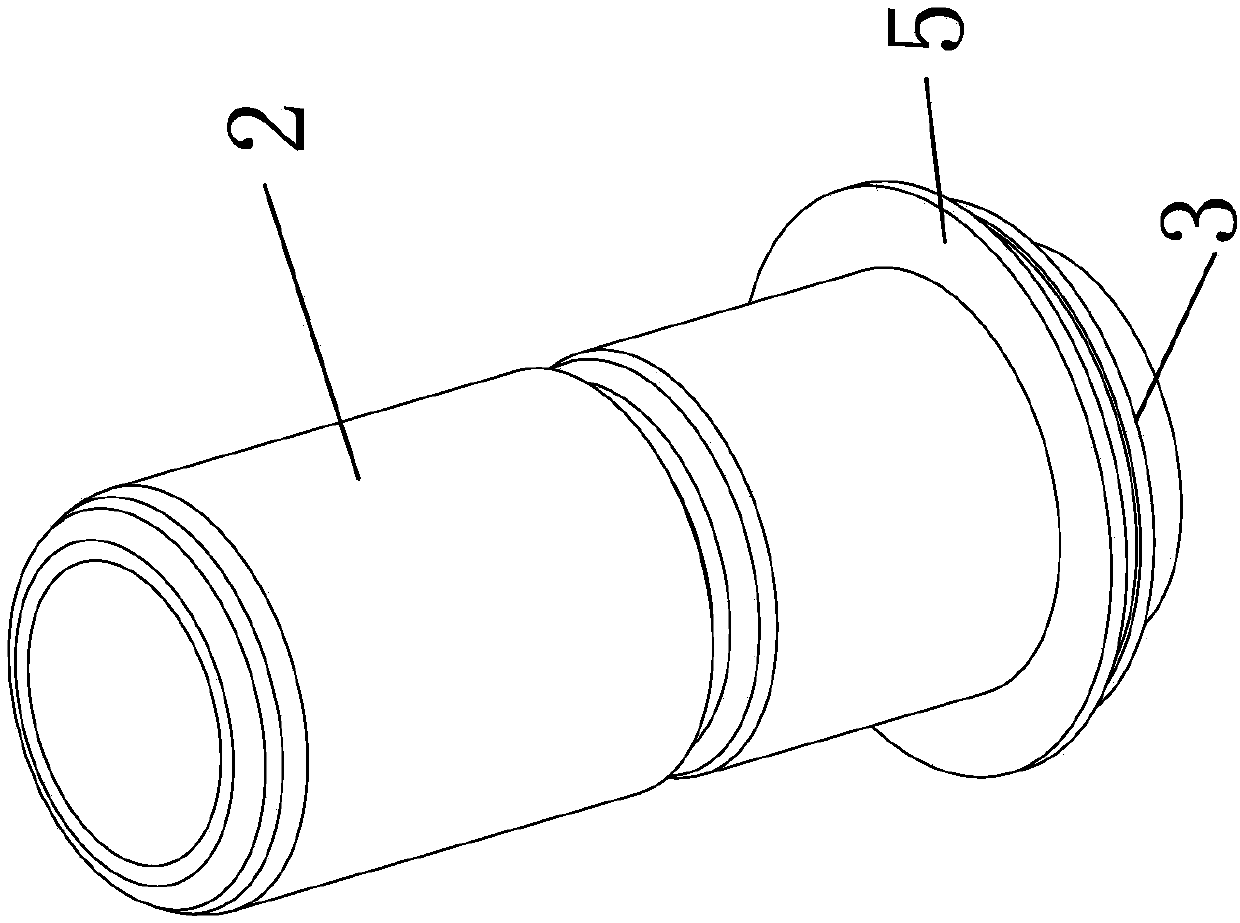

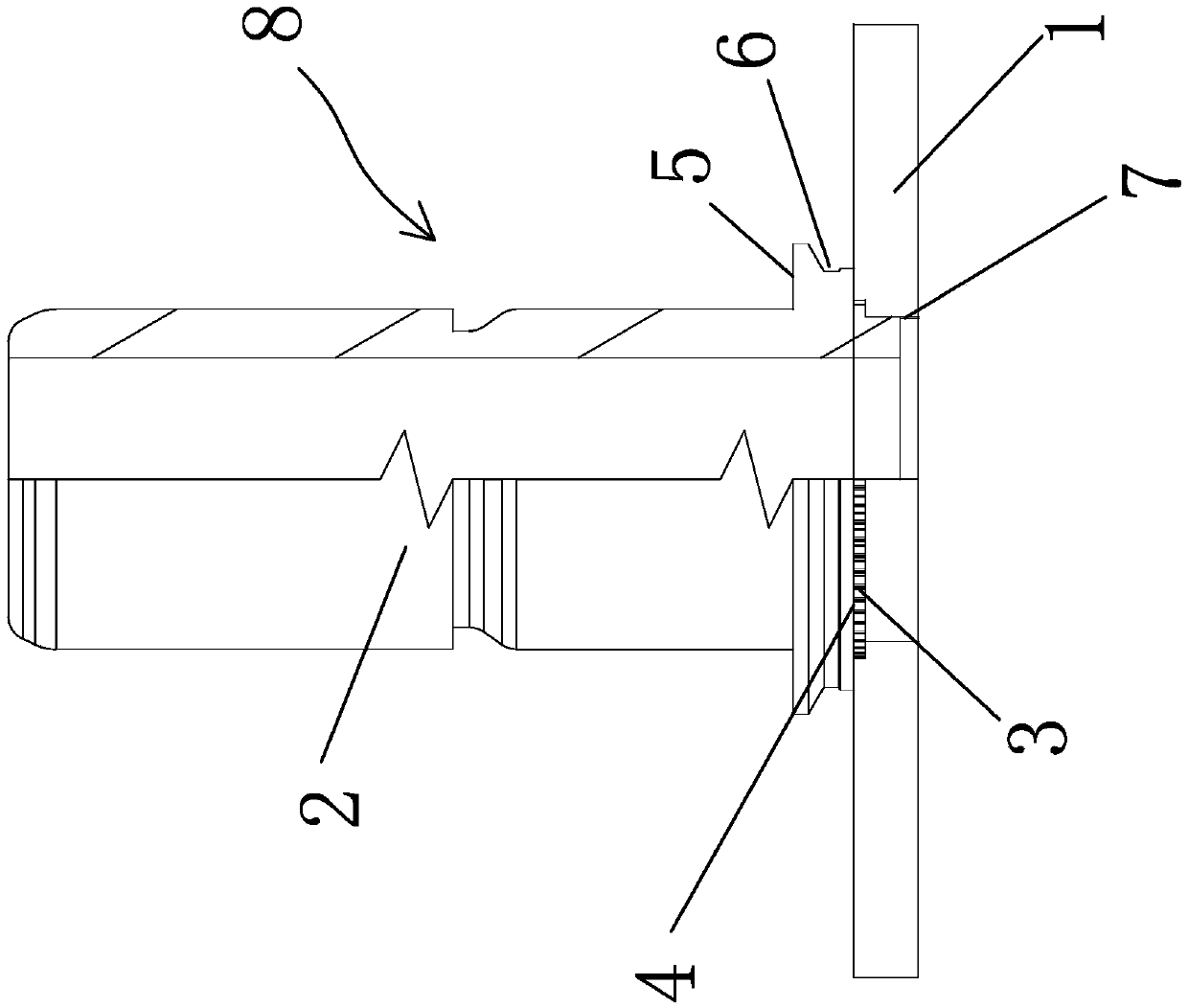

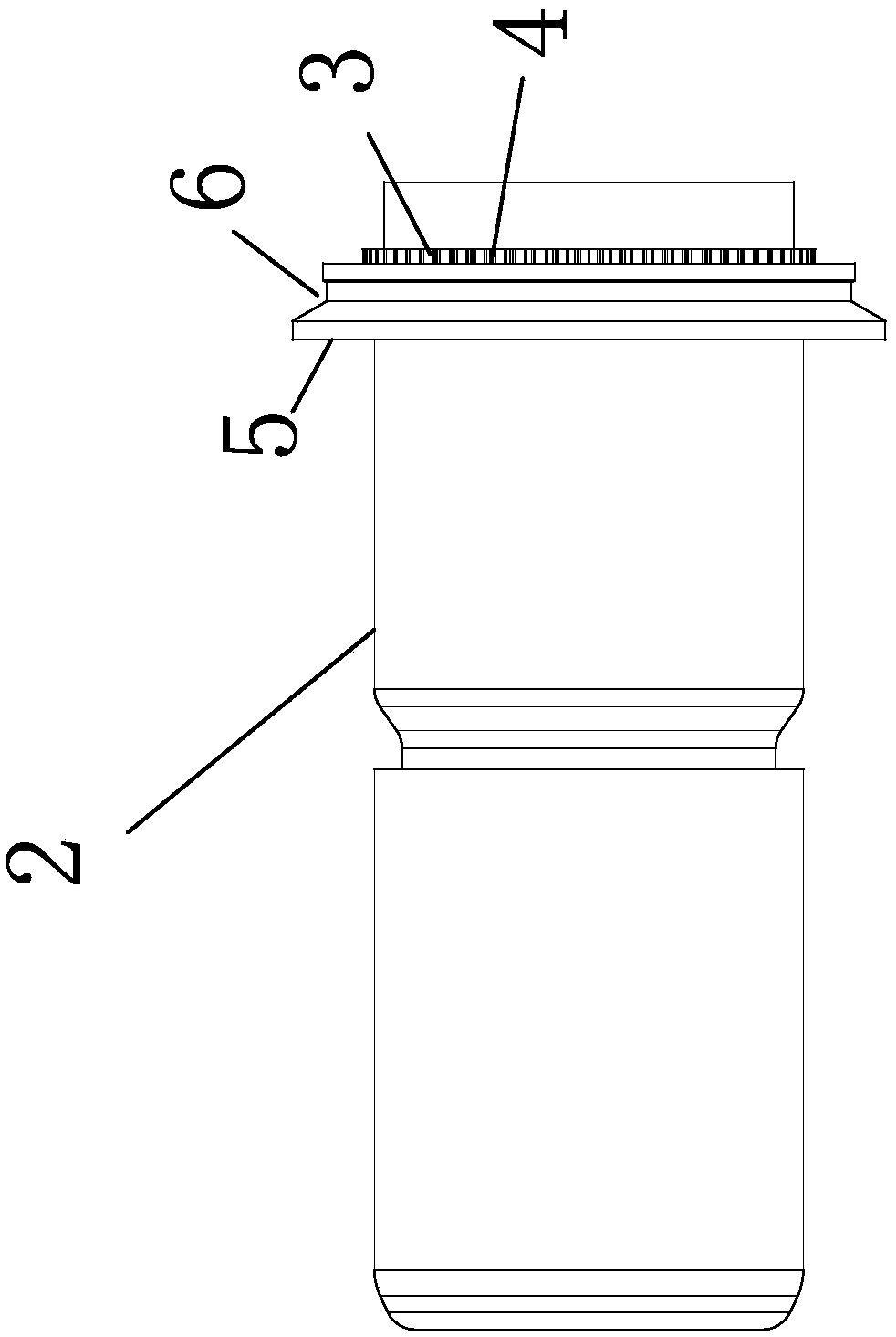

[0014] In the figure, the aluminum alloy water-cooled plate 1; the main body 2; the hobbing 3; the waterproof sealant layer 4; the circular flange surface 5; the interface glue storage tank 6; the water inlet and outlet 7;

[0015] like figure 1 , figure 2 as well as image 3 As shown in the figure, the pressure riveting water pipe joint with sealing performance for the water cooling plate of the battery box is used to realize the sealing and firm connection of the water pipe joint and the aluminum alloy water cooling plate 1, and includes a main body 2. The material of the main body 2 is high-strength aluminum alloy. 2 is a hollow cylinder structure. One end of the main body 2 is provided with hobbing 3. The periphery of the hobbing 3 is pro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com