Solder paste laser-induced forward transfer device and method

A technology of laser induction and transfer equipment, applied in laser welding equipment, welding equipment, welding equipment and other directions, can solve the problems of inability to meet small-scale rapid production, high cost, long cycle, etc., to shorten the production cycle, simplify the production process, The effect of reducing production costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

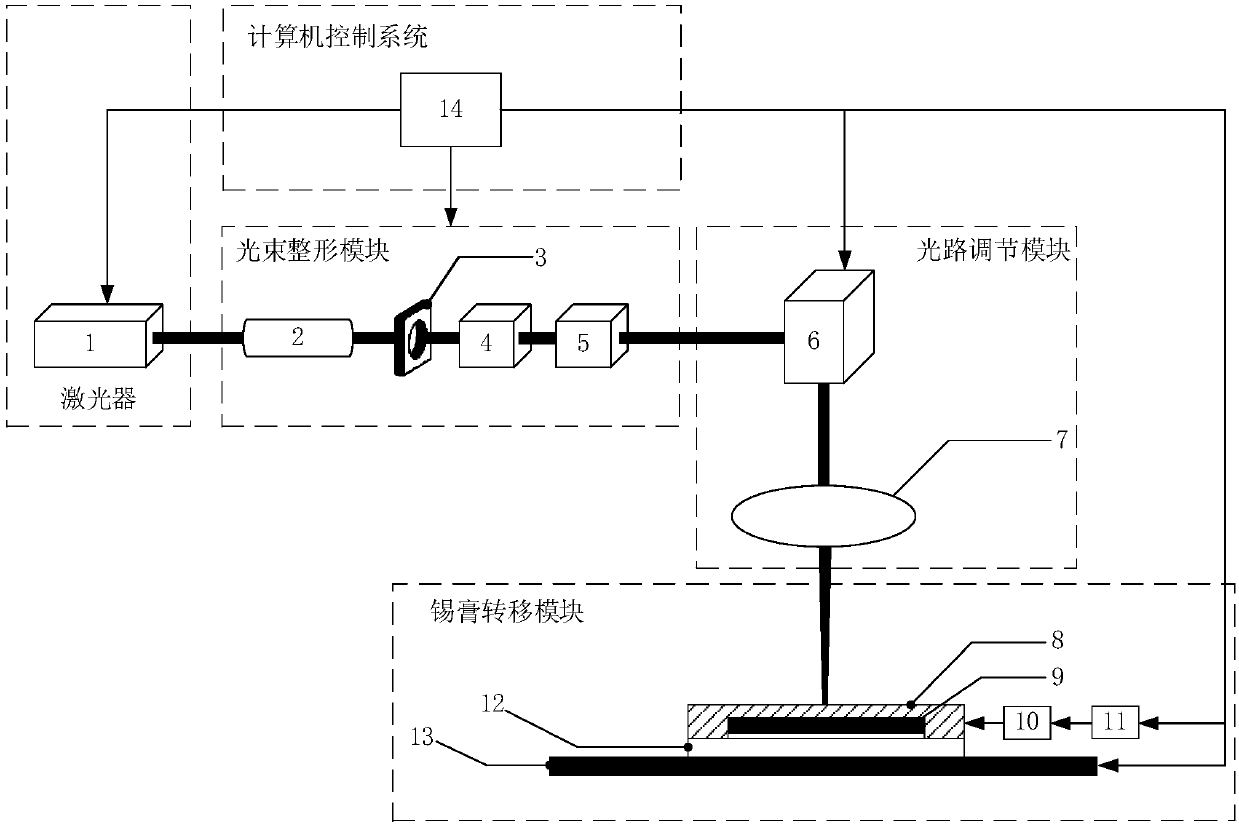

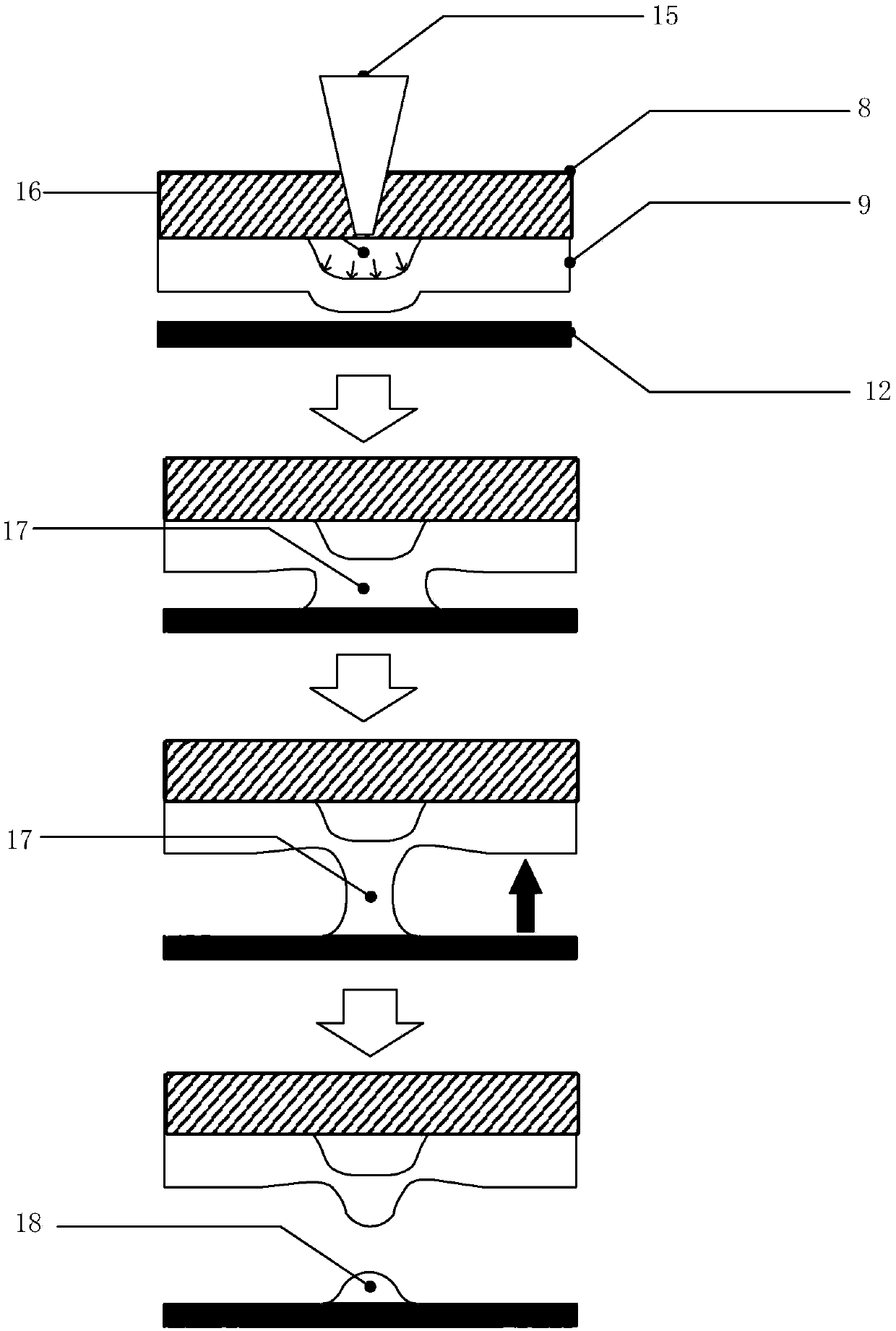

[0034] Such as Figure 1-4 shown. The invention discloses a solder paste laser-induced forward transfer device, which includes a laser unit and a computer control system 14, and is characterized in that: it also includes a solder paste transfer module; the computer control system 14 controls the laser beam output of the laser unit and the solder paste movement of the paste transfer module;

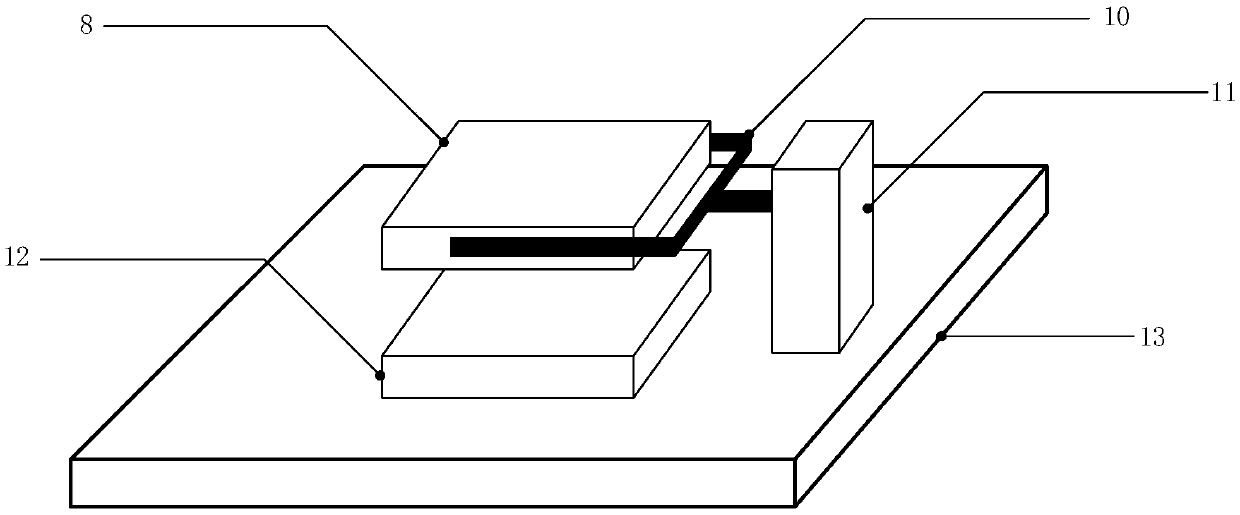

[0035] The solder paste transfer module includes a transparent substrate 8, a fixture 10, a Z-axis lifting platform 11, a receiving substrate 12, and an XYZ-axis moving platform 13;

[0036] The lower surface of the transparent substrate 8 is a concave surface for accommodating the solder paste film 9; the transparent substrate 8 is quartz glass or other transparent objects.

[0037] The receiving substrate 12 and the Z-axis lifting platform 11 are placed on the XYZ axis moving platform 13 to adjust the relative position of the receiving substrate 12 and the laser beam spot;

[0038] Th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com