A kind of inalsb infrared detector surface passivation method

An infrared detector and detector chip technology, applied in the field of infrared detectors, can solve the problems of low reliability, high power consumption of infrared detector components, large volume, etc., to increase surface resistivity, reduce surface recombination rate and surface Effect of leakage current

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

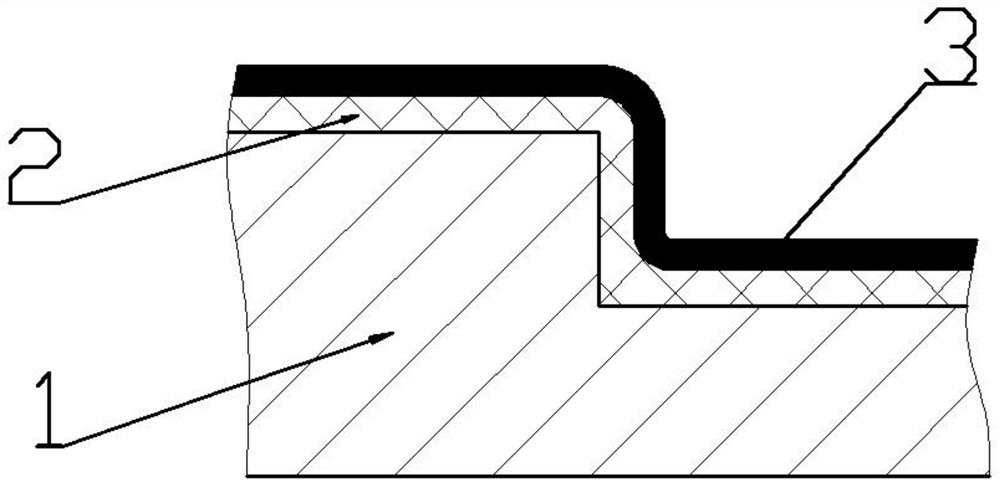

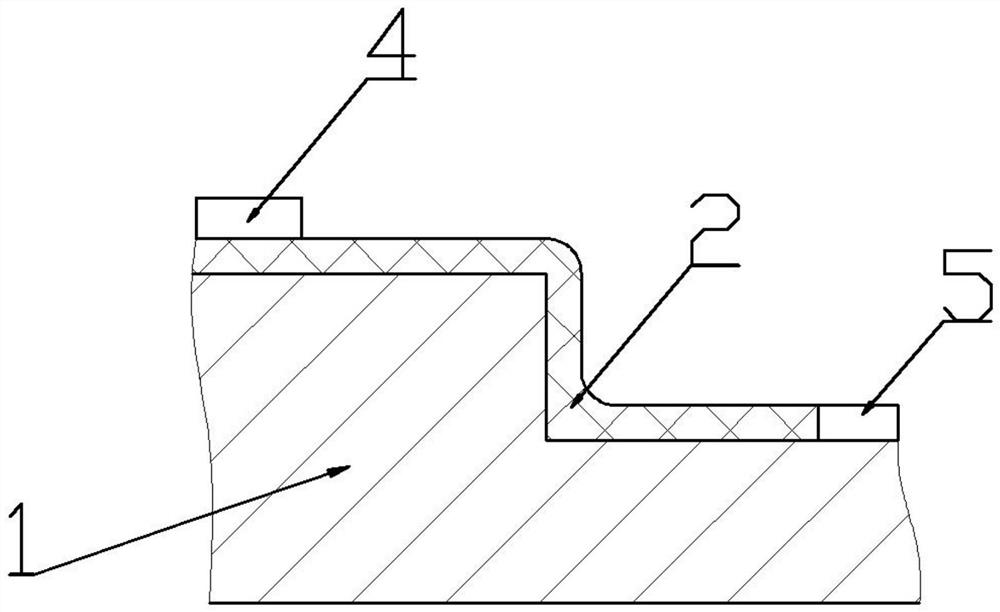

Image

Examples

Embodiment 1

[0034]Example 1 The inalsb infrared detector chip passes the test results completed by optical and electrical test equipment:

[0035]Table 1 Performance test results of the infrared device of the above embodiment

[0036]

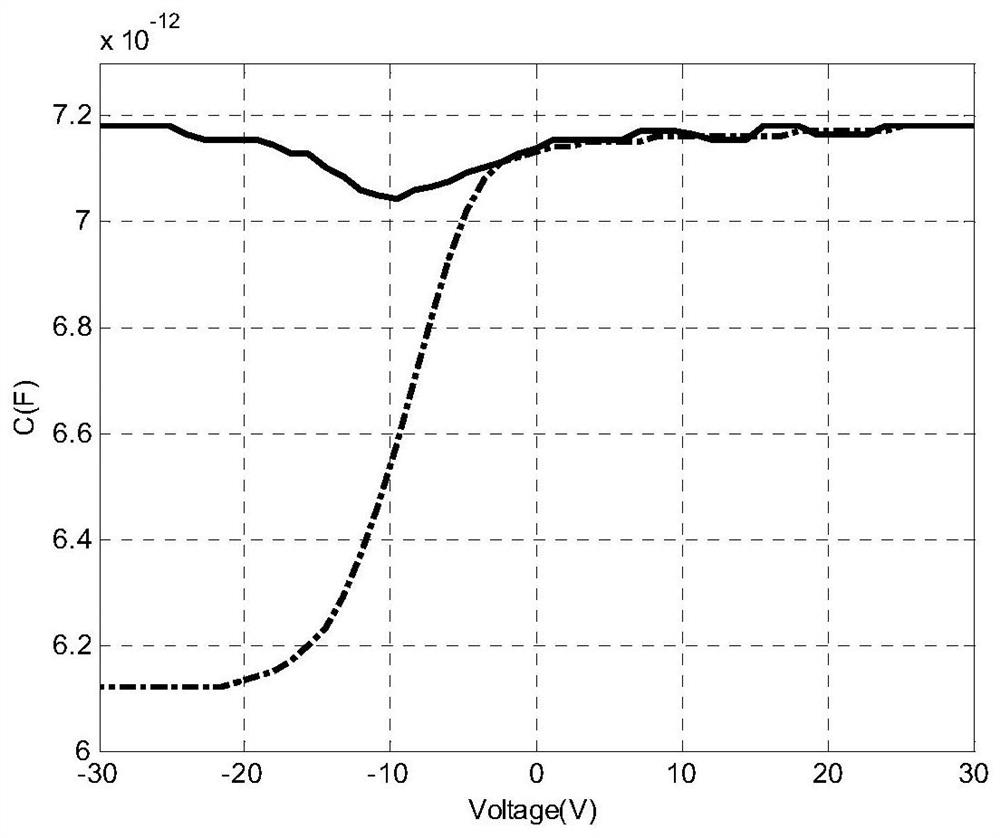

[0037]Table 2. MIS structure calculation results of the passivation film of the above embodiment

[0038]

[0039]By test structure analysis of Table 1, Table 2, the passivation method has a good passivation effect on the surface of the INALSB material, which can effectively reduce surface composite rates and increase surface resistance.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com