Reproducible manufacturing method for increasing the wavelength of mass-produced MOCVD gallium nitride LED

A manufacturing method and gallium nitride technology, applied in the direction of electrical components, circuits, semiconductor devices, etc., can solve the problems of reduced repeatability of wavelength, achieve the effect of reducing instability and improving repeatability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] Hereinafter, specific implementations of the method for improving the repeatability of the wavelength of the mass-produced MOCVD gallium nitride LED in the present invention will be described in detail with reference to the accompanying drawings, so that the technical content, structural features, objectives and effects of the present invention will be described in detail.

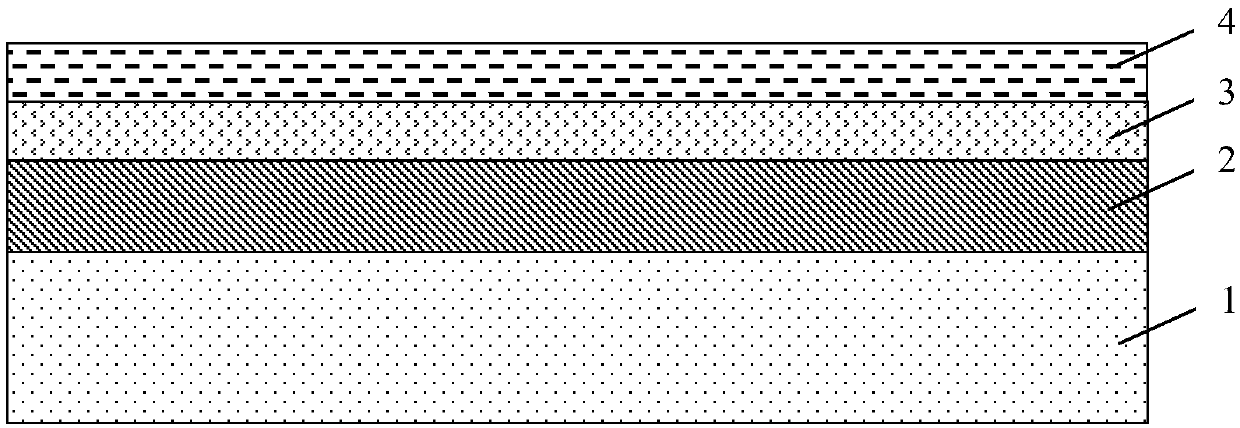

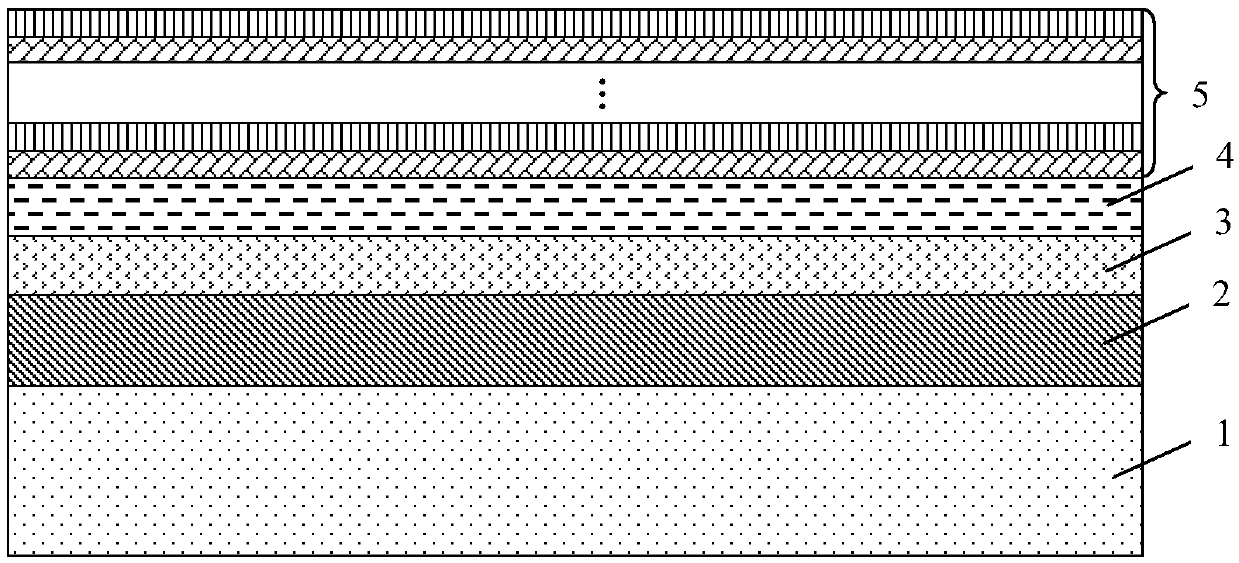

[0024] The present invention provides a method for improving the repeatability of the wavelength of a mass-produced MOCVD gallium nitride LED. The epitaxial structure of the LED includes from bottom to top: Buffer layer, U-GaN layer, N-GaN layer, MQW structure layer, The P-AlGaN layer, the P-GaN layer, and the P+GaN layer specifically include the following steps:

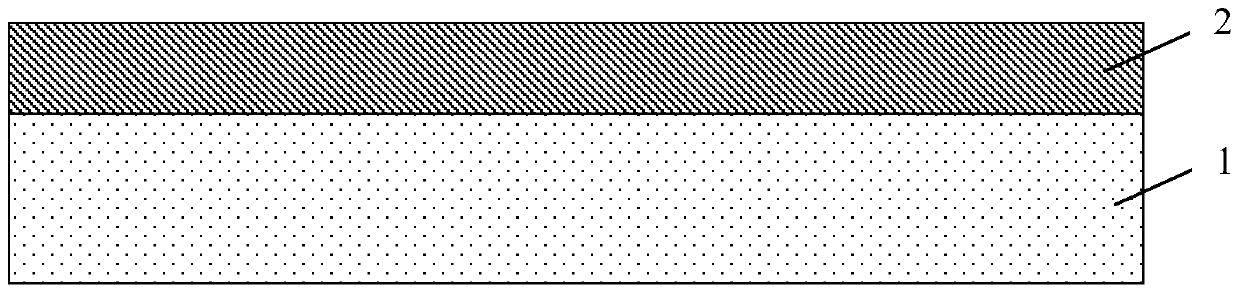

[0025] S1, such as figure 1 As shown, a substrate 1 is provided, and a buffer layer 2 is grown on the substrate 1.

[0026] Wherein, the substrate 1 can be made of any material suitable for the growth of GaN (gallium nitride) and its semiconduc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com