A kind of inorganic permeable brick and its preparation process

A permeable brick, inorganic technology, applied in the field of inorganic permeable bricks and its preparation process, can solve the problems of resin permeable bricks such as weak aging resistance, poor freeze-thaw resistance, and insufficient compactness, and achieve durability and good water permeability. Effects of improving freeze-thaw resistance and improving aging resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

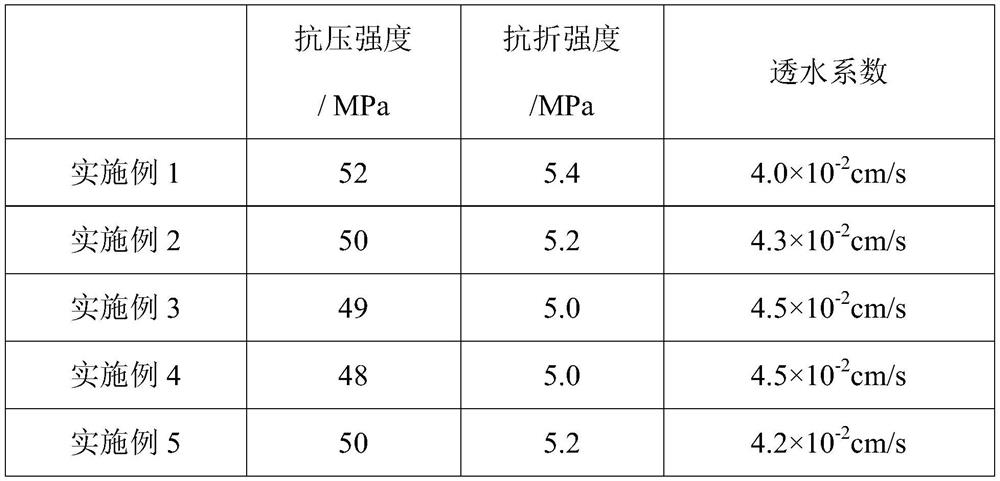

Examples

Embodiment 1

[0037] This embodiment provides an inorganic permeable brick and a preparation method thereof. The inorganic permeable brick includes a water-permeable surface layer and a water-permeable bottom layer. The thickness ratio of the water-permeable surface layer and the water-permeable bottom layer is 10:60. The raw materials of the water-permeable surface layer are as follows: 1g of silica sand with a particle size of 30-100 mesh, silicate 0.03g of parasitic compound, 0.02g of cement coated with silica sand (named as the first cement), 0.0006g of carbon black, 0.02g of acrylic emulsion, 0.20g of cement (named as the second cement), 0.001g of hydroxypropyl methylcellulose ; The silicate compound is sodium silicate;

[0038] The raw materials of the permeable bottom layer are as follows: 1g of stones with a particle size of 2-13mm, 0.23g of cement (named as the third cement) covering the stones;

[0039] The preparation method of above-mentioned inorganic permeable brick, comprise...

Embodiment 2

[0045] This embodiment provides an inorganic permeable brick and a preparation method thereof. The inorganic permeable brick includes a water-permeable surface layer and a water-permeable bottom layer. The thickness ratio of the water-permeable surface layer and the water-permeable bottom layer is 4:50. The raw materials of the water-permeable surface layer are as follows: 1g of silica sand with a particle size of 20-140 mesh, silicate Compound 0.01g, cement coated with silica sand (named the first cement) 0.03g, iron red 0.00003g, acrylic emulsion 0.01g, cement (named the second cement) 0.35g, hydroxypropyl methylcellulose 0.0006g ; The silicate compound is sodium silicate;

[0046] The raw materials of the permeable bottom layer are as follows: 1g of stones with a particle size of 2-20mm, 0.18g of cement (named as the third cement) covering the stones;

[0047] The preparation method of above-mentioned inorganic permeable brick, comprises the steps:

[0048] 1) Aggregate c...

Embodiment 3

[0053] This embodiment provides an inorganic permeable brick and a preparation method thereof. The inorganic permeable brick includes a water-permeable surface layer and a water-permeable bottom layer. The thickness ratio of the water-permeable surface layer and the water-permeable bottom layer is 15:200. The raw materials of the water-permeable surface layer are as follows: 1g of silica sand with a particle size of 20-140 mesh, silicate 0.05g of parasitic compound, 0.01g of cement coated with silica sand (named as the first cement), 0.0005g of phthalocyanine blue, 0.05g of acrylic emulsion, 0.35g of cement (named as the second cement), 0.0009 hydroxypropyl methylcellulose g; the silicate compound is sodium silicate;

[0054] The raw materials of the permeable bottom layer are as follows: 1g of stones with a particle size of 2-20mm, 0.3g of cement (named as the third cement) covering the stones;

[0055] The preparation method of above-mentioned inorganic permeable brick, com...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size (mesh) | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle size (mesh) | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com