Pavement asphalt modifier, modified pavement asphalt, as well as preparation method thereof and asphalt mixture

A technology for asphalt mixture and road asphalt, which is used in building thermal insulation materials, building components, buildings, etc., can solve the problems of high system viscosity, difficult material transportation, and high cost, achieve high water stability and anti-rutting performance, and promote uniformity. Hybrid, low-cost effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0028] According to the second aspect of the present invention, the present invention provides the preparation method of the road asphalt modifier described in the first aspect of the present invention, the method comprising: heating and melting the direct coal liquefaction asphalt, and mixing the petroleum heavy oil After preheating, the two are stirred evenly, and then cooled to obtain the road asphalt modifier.

[0029]According to the preparation method of the present invention, the heating and melting can be carried out at any temperature that can melt the coal directly liquefied bitumen without changing the properties of the bitumen. From the perspective of shortening the stirring time and further reducing the viscosity of the system, it is preferable that the heating and melting temperature is 50-100° C. higher than the softening point of the coal direct liquefaction pitch.

[0030] According to the preparation method of the present invention, it is preferred that the m...

Embodiment 1

[0064] (1) Preparation of road asphalt modifier

[0065] The coal direct liquefaction bitumen (softening point is 180° C.) is pulverized and dried to obtain a coal direct liquefaction bitumen powder with a particle diameter of less than 3 mm and a water content of less than 0.5% by weight. Heat the powder to 250°C to melt, and preheat the petroleum heavy oil component A to 180°C, then mix the two at 230°C with a weight ratio of 100:8 and stir evenly, and after cooling, grind them into pieces smaller than 5mm Granules to obtain road asphalt modifier.

[0066] (2) Preparation of modified road asphalt

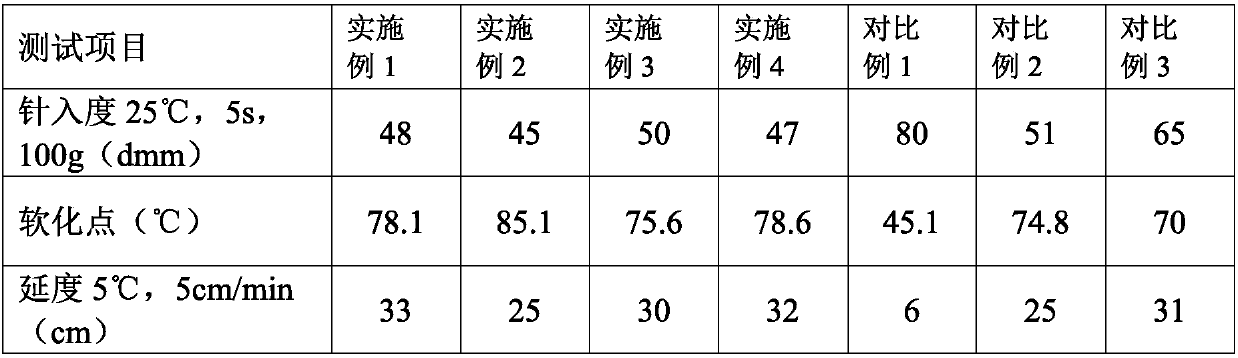

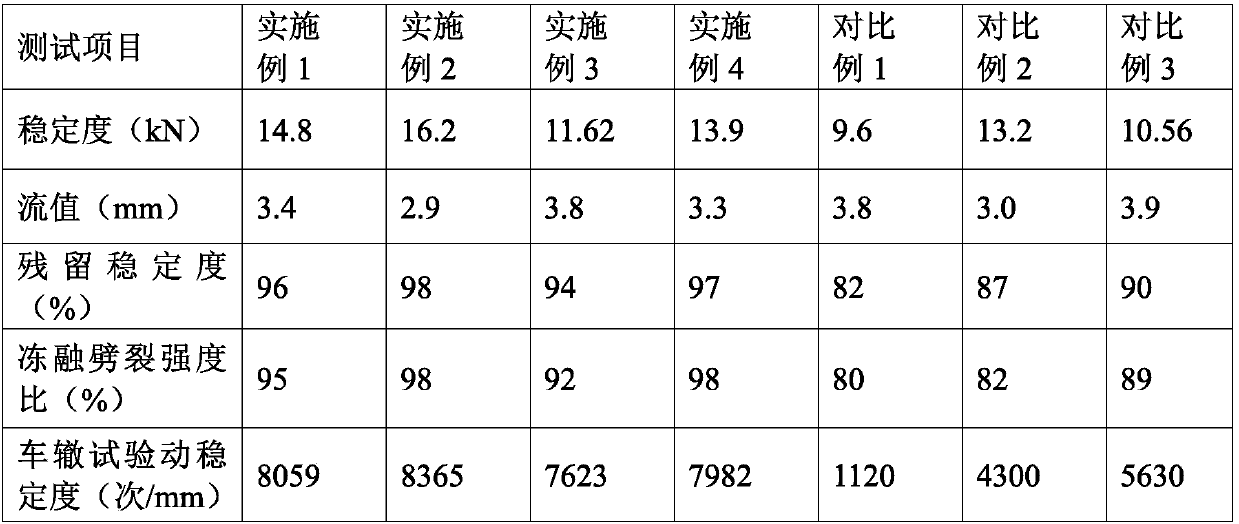

[0067] The road asphalt modifier is mixed with 15% by weight and 4% by weight of SBS1301, 81% by weight of 90# petroleum asphalt, and in a shear emulsifier at 150°C, it is 30m / s high-speed shear 30 Minutes, then continue to stir for 1 hour with a linear velocity of 1m / s to obtain modified road asphalt, the performance of this product is shown in Table 3.

[0068](3) Preparation...

Embodiment 2

[0075] (1) Preparation of road asphalt modifier

[0076] The coal direct liquefaction bitumen (softening point is 200 DEG C) is pulverized and dried to obtain the coal direct liquefaction bitumen powder with a particle size of less than 3mm and a water content of less than 0.5% by weight. Heat the powder to 280°C to melt, and at the same time, preheat petroleum heavy oil component A to 180°C, then mix the two at 230°C in a weight ratio of 100:1 and stir evenly, and after cooling, crush them into smaller than 5mm Granules to obtain road asphalt modifier.

[0077] (2) Preparation of modified road asphalt

[0078] The road asphalt modifier is mixed with 20% by weight and 3.8% by weight of SBS1301, 76.2% by weight of 70# petroleum asphalt, and first sheared at a high speed of 25m / s for 35 minutes at 170°C in a shear emulsifier , and then continue to stir for 0.5 hours at a line speed of 1 m / s to obtain modified road asphalt. The properties of the product are shown in Table 3.

...

PUM

| Property | Measurement | Unit |

|---|---|---|

| softening point | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| softening point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com