Processing method of blueberry fruit wine

A processing method and technology for blueberry fruit wine, which are applied in the preparation of alcoholic beverages and other directions, can solve problems such as being unfavorable for wide-scale promotion, and achieve the effects of reducing loss, reducing sourness and improving retention.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

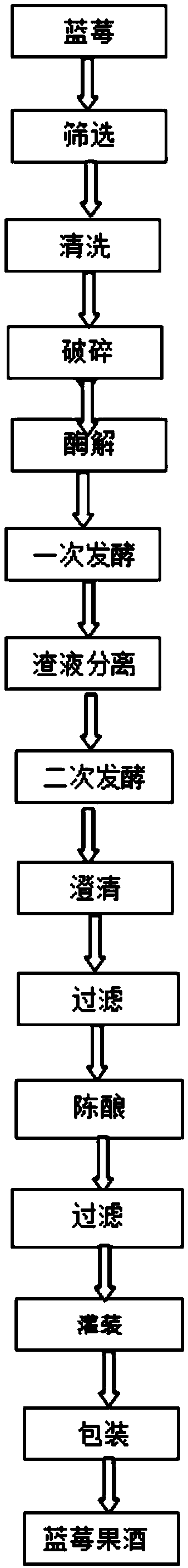

[0040] A processing method of blueberry fruit wine, the processing method includes the following steps in sequence: screening→cleaning→crushing→enzymolysis→primary fermentation→slag liquid separation→secondary fermentation→clarification→filtering→aging→filtering→filling→packaging→ Blueberry Wine Products

[0041] specific:

[0042] Crushing: Fresh blueberry fruit or frozen blueberry fruit after thawing, after screening and cleaning, add 30mg / kg of SO 2 , crushed at a low temperature <35°C and allowed to stand for 8 hours;

[0043]Enzymolysis: add 0.5g / kg glycine, 2.0g / kg ascorbic acid, 0.5g / kg tea polyphenols, 3.0g / kg grape seed extract, 10mg / kg to the crushed blueberry slurry by weight of blueberries kg of pectinase, and the enzyme activity is greater than 10000u / g, enzymatically hydrolyzed at 45°C for 10h;

[0044] Primary fermentation: adding sucrose after enzymolysis to adjust the blueberry slurry to 20°Brix, inoculating 250 mg / kg of activated Saccharomyces cerevisiae, ...

Embodiment 2

[0051] A processing method of blueberry fruit wine, the processing method includes the following steps in sequence: screening→cleaning→crushing→enzymolysis→primary fermentation→slag liquid separation→secondary fermentation→clarification→filtering→aging→filtering→filling→packaging→ Blueberry Wine Products

[0052] specific:

[0053] Crushing: Fresh blueberry fruit or frozen blueberry fruit after thawing, after screening and cleaning, add 60mg / kg of SO 2 , crushed at a low temperature <35°C and allowed to stand for 4 hours;

[0054] Enzymolysis: add 1.5g / kg glycine, 0.5g / kg ascorbic acid, 1.0g / kg tea polyphenols, 1.0g / kg grape seed extract, 30mg / kg kg of pectinase, and the enzyme activity is greater than 10000u / g, enzymolysis at 35°C for 20h;

[0055] Primary fermentation: adding sucrose after enzymolysis to adjust the blueberry slurry to 22°Brix, inoculating 150mg / kg of activated Saccharomyces cerevisiae, and fermenting at 30°C for 7 days.

[0056] Slag-liquid separation: u...

Embodiment 3

[0062] A processing method of blueberry fruit wine, the processing method includes the following steps in sequence: screening→cleaning→crushing→enzymolysis→primary fermentation→slag liquid separation→secondary fermentation→clarification→filtering→aging→filtering→filling→packaging→ Blueberry Wine Products

[0063] specific:

[0064] Crushing: Fresh blueberry fruit or frozen blueberry fruit after thawing, after screening and cleaning, add 60mg / kg of SO 2 , crushed at a low temperature <35°C and allowed to stand for 8 hours;

[0065] Enzymolysis: add 0.5g / kg glycine, 2.0g / kg ascorbic acid, 0.5g / kg tea polyphenols, 3.0g / kg grape seed extract, 10mg / kg to the crushed blueberry slurry by weight of blueberries kg of pectinase, and the enzyme activity is greater than 10000u / g, enzymatically hydrolyzed at 45°C for 10h;

[0066] Primary fermentation: After enzymolysis, add sucrose to adjust the blueberry slurry to 20°Brix, inoculate 150mg / kg of activated Saccharomyces cerevisiae, ferm...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com