Structure of prefabricated precast concrete retaining wall bottom plate and vertical plate

A prefabricated concrete and retaining wall technology, applied in the construction field, can solve problems such as insufficient bolt anchorage length, affecting the strength of the retaining wall, and affecting the production period, so as to save labor, shorten the construction period, and reduce labor intensity.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

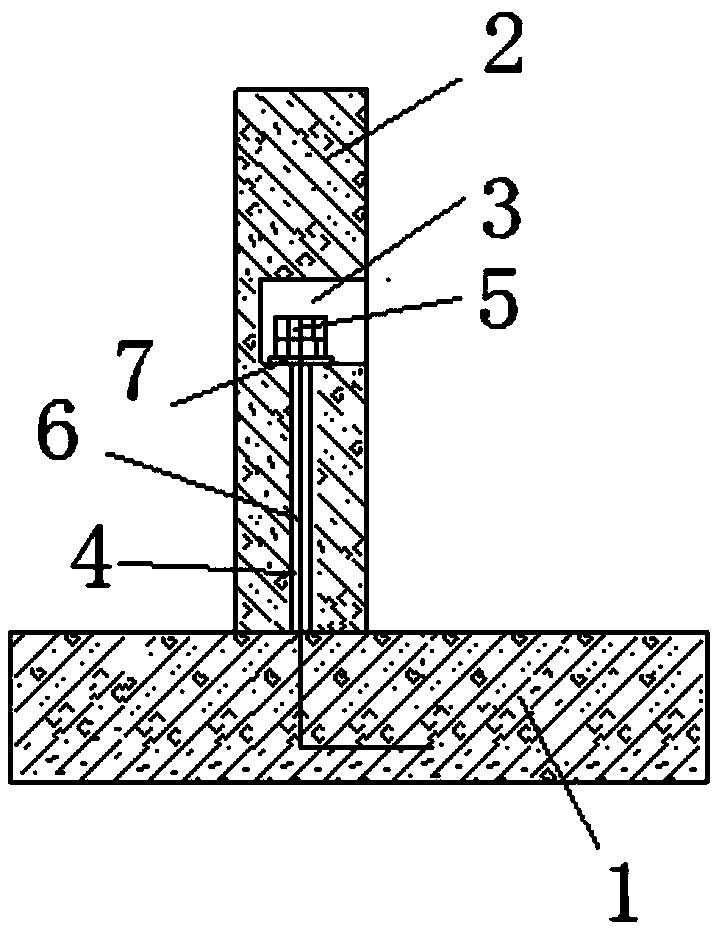

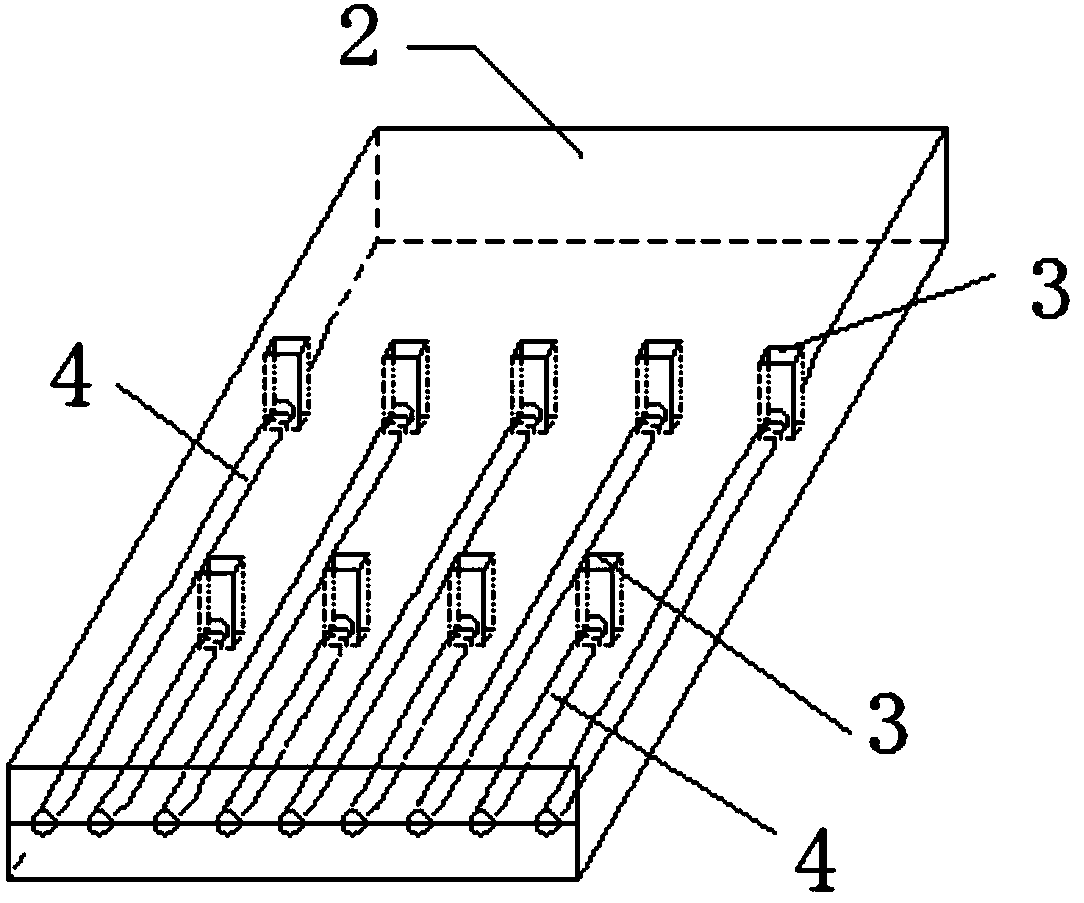

[0024] Embodiment 1: as figure 1 As shown, a prefabricated prefabricated concrete retaining wall base plate and vertical wall structure, including the retaining wall base plate 1 and the retaining wall vertical plate 2, the vertical plate 1 is reserved according to the set one-word equidistant array orientation The hole 3 communicates with the anchor hole 4, and the anchor hole 4 communicates with the nut hole 3, and the height of the nut hole 3 is greater than the sum of the heights of the three nuts 5. An anchor 6 is pre-embedded in the bottom plate 1 according to the same orientation. The anchor 6 has sufficient length and its top end passes through the anchor hole 4 to be fixedly connected with the double nut 5 and the washer 7 inserted into the nut hole 3. The nut 5. Double nuts are used to superimpose and tighten each other to resist shearing and loosening.

[0025] The connection between the long enough anchor 6 and the nut 5 not only avoids on-site welding and casting...

Embodiment 2

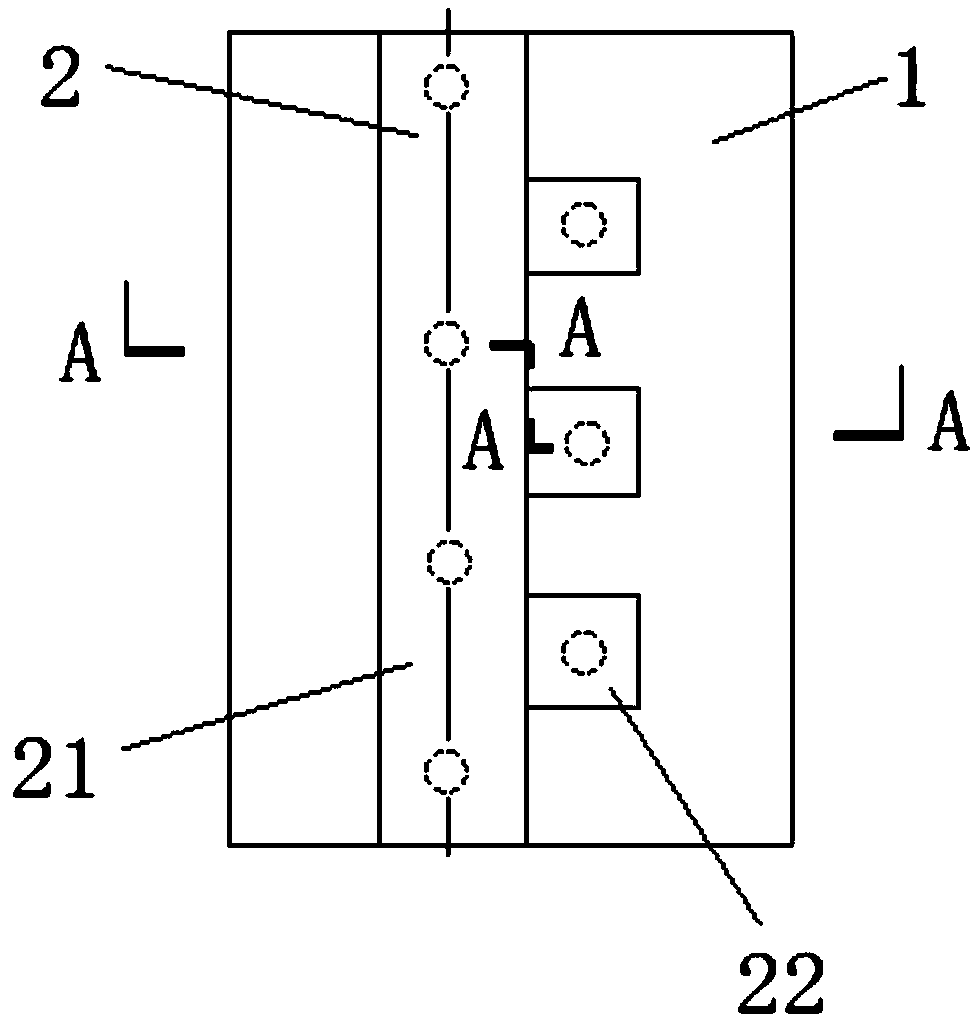

[0028] Embodiment 2: the vertical plate 2 is formed by integral casting of the main board 21 and the steps 22, and several steps 22 are arranged according to the specific conditions, and the height of the steps 22 is lower than the main board 21, and the nut holes 3 and the The orientations of the anchor holes 4 and the anchors 6 are staggered according to a triangle relationship, and the position of the apex of the triangle relationship corresponds to the center point of the step 22 . Since the cantilever or buttress retaining wall is a bending-shear component, the prefabricated parts are generally split at the intersection of the vertical plate 2 and the bottom plate 1. reliability, it is meaningful to add a step 22 on the rear side of the bottom of the vertical plate 2 for bending and shearing resistance, and the rest of the structure is the same as that of embodiment 1, see image 3 , Figure 4 ,in image 3 The small and medium circles show the distribution positions of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com