Double-layer dynamic seal device with damping function

A double-layer sealing and dynamic sealing technology, which is applied to engine sealing, engine components, non-rotational vibration suppression, etc., can solve the problems of non-continuous feeding, low production efficiency, etc., achieve convenient operation, reduce requirements, and ensure safety Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The present invention will be further explained below in conjunction with specific embodiments.

[0023] A double-layer sealing device with damping energy mainly includes: a cooling system, a shock-absorbing bearing support mechanism, a main fixing body and a double-layer sealing mechanism.

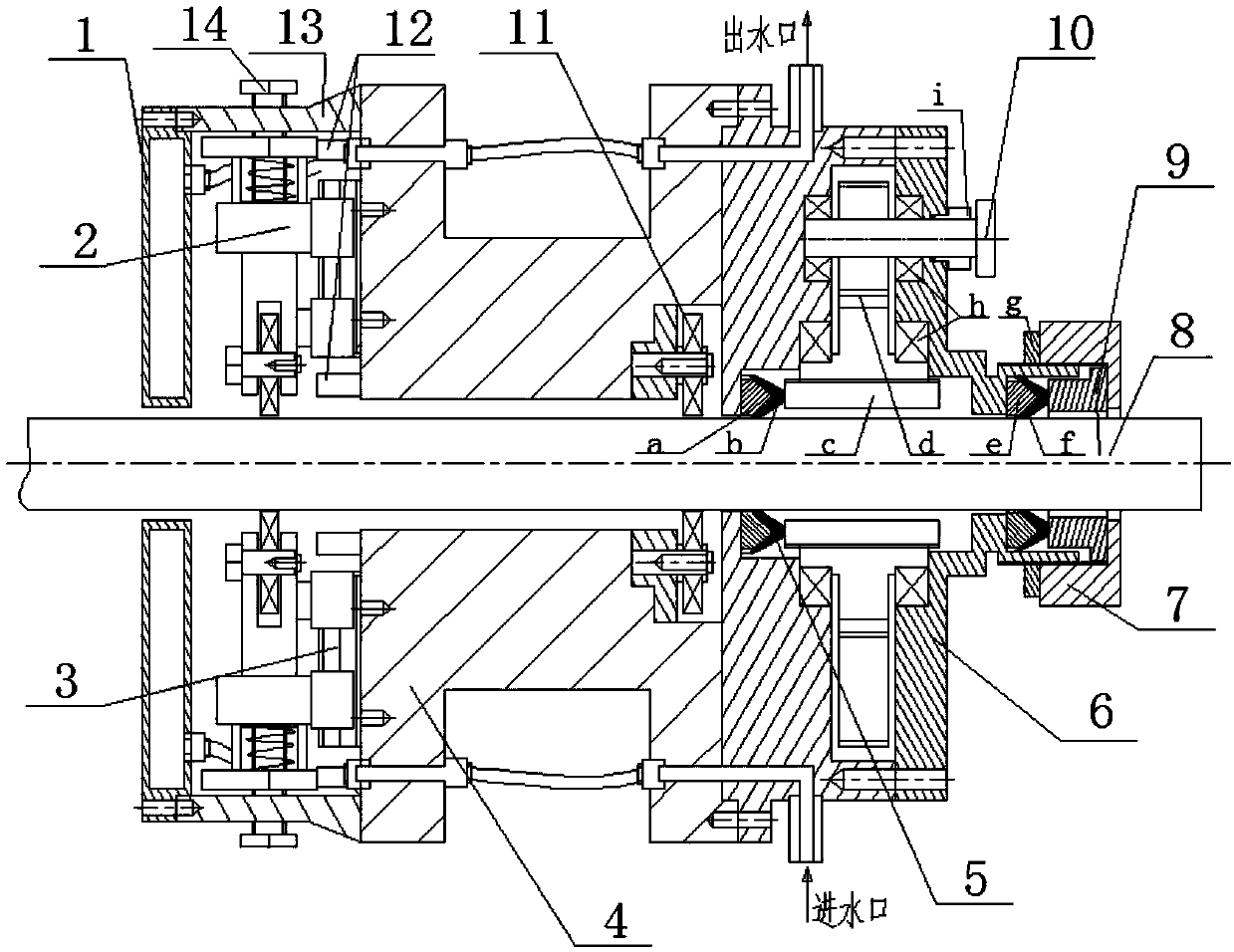

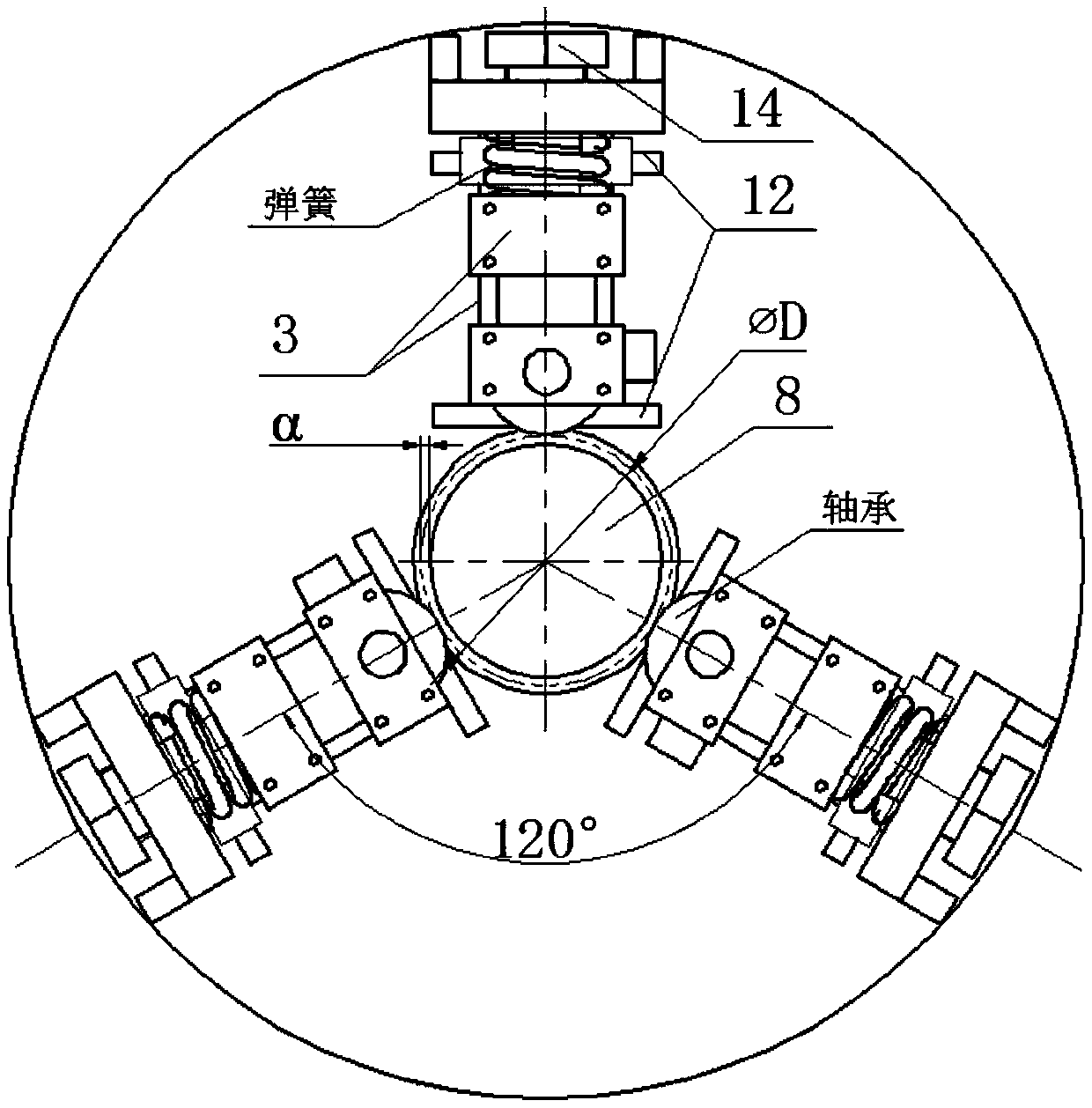

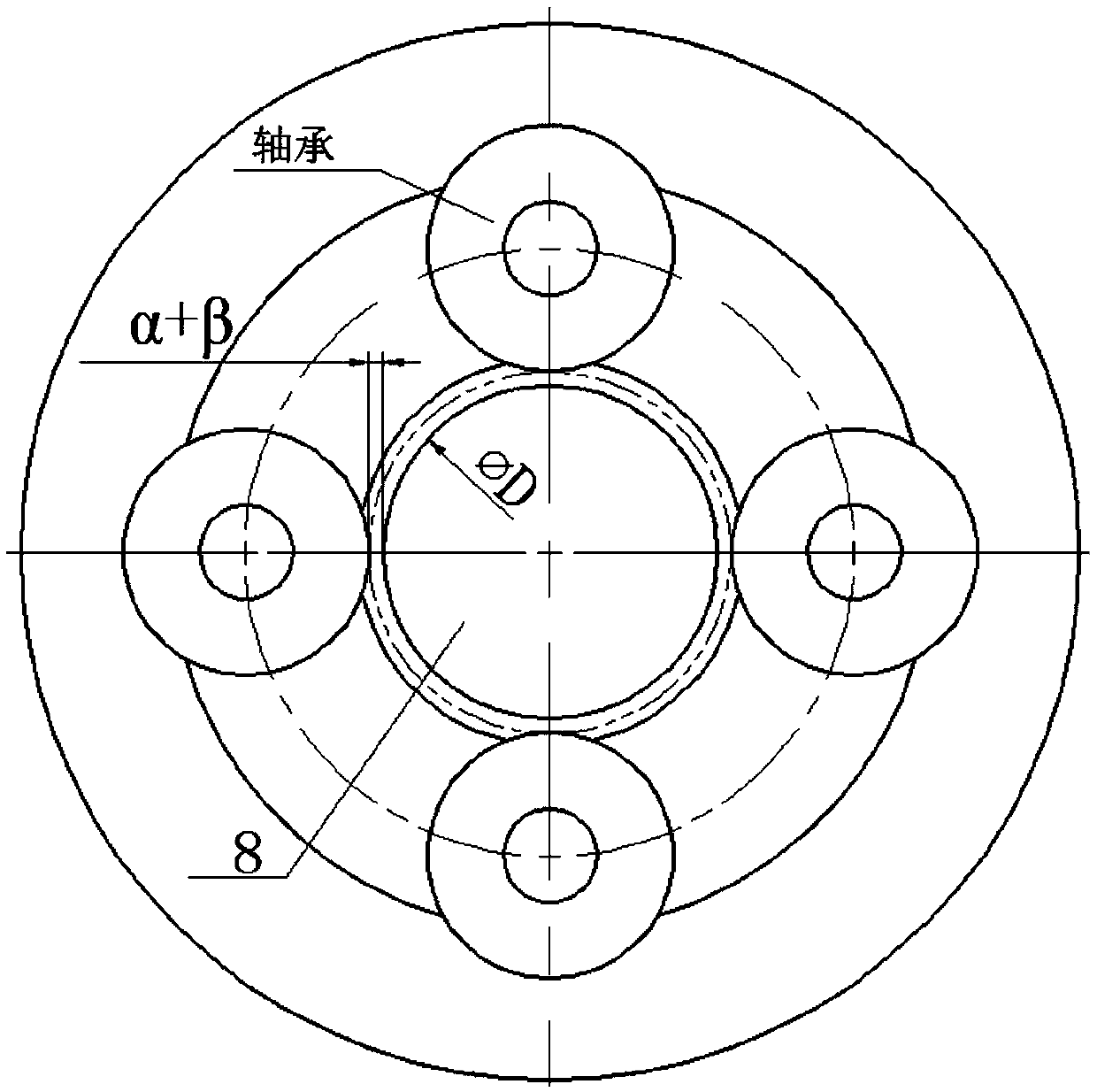

[0024] Specifically, such as figure 1 As shown, the main fixed body is a main fixed round shaft sleeve, and its front end is a water-cooled disc 1. The shock-absorbing bearing support mechanism mainly includes a spring shock absorber 2, a sliding rail slider 3, a limit device 12, a spring compression bolt 14 and a support bearing. The fixed round shaft sleeve 4 is machined with positioning dimensions and threaded holes for installing the front shock-absorbing bearing support mechanism and the double-layer sealing structure, and 4-6 rigid support bearings 11 are distributed along the circumference of the fixed round shaft sleeve 4. The double-layer sealing mechanism mainly includes an i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com