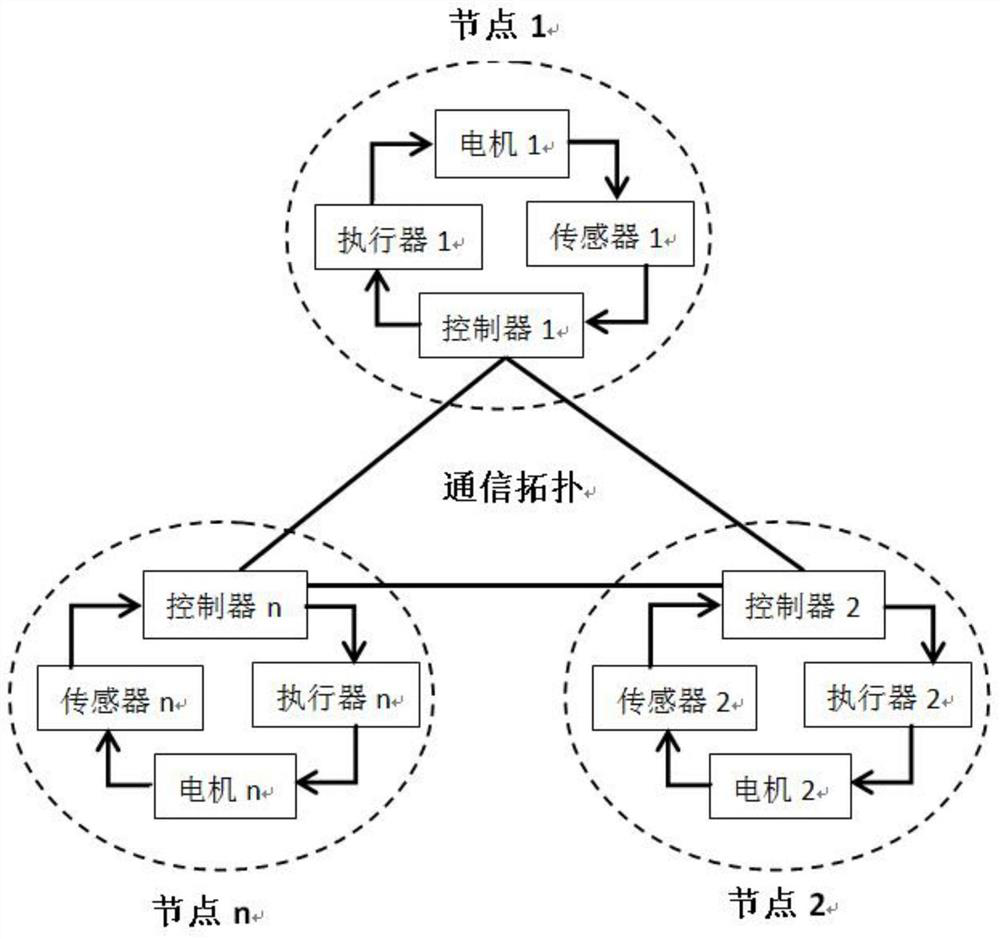

A Distributed Adaptive Coordinated Control Method for Multi-Permanent Magnet Synchronous Motor

A permanent magnet synchronous motor, coordinated control technology, applied in motor control, multiple motor speed/torque control, AC motor control and other directions, can solve the control structure and control algorithm limitations, control method limitations, poor system anti-interference ability and other problems, to achieve the effect of enhancing robustness and anti-interference ability and reducing complexity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0045] A simulation case is given below to verify the effectiveness and correctness of the control method proposed by the present invention.

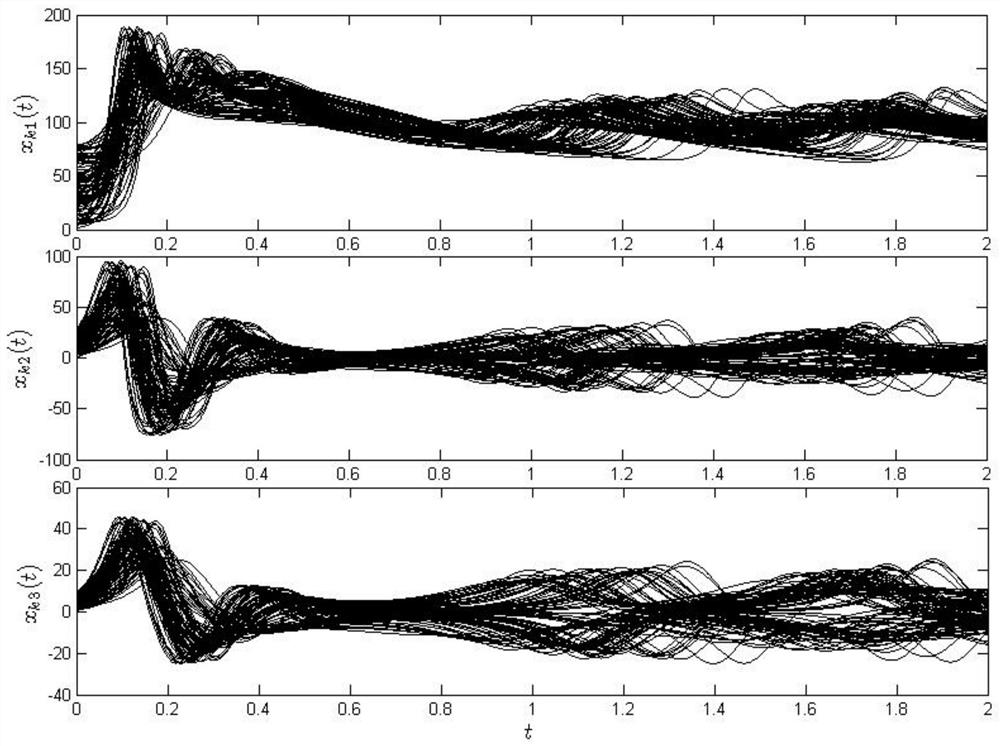

[0046] When γ=100, σ=10, and no control is applied, the dynamic model of n permanent magnet synchronous motors controlled exhibit chaotic dynamic behavior. When the number of permanent magnet synchronous motors is n=100, the simulation results without any control are as follows Figure 1-2 shown.

[0047]The results show that when no control is applied, the state variables of all permanent magnet synchronous motors exhibit a disorganized state. Therefore, in order to achieve coordinated operation of all PMSMs, a suitable controller needs to be designed.

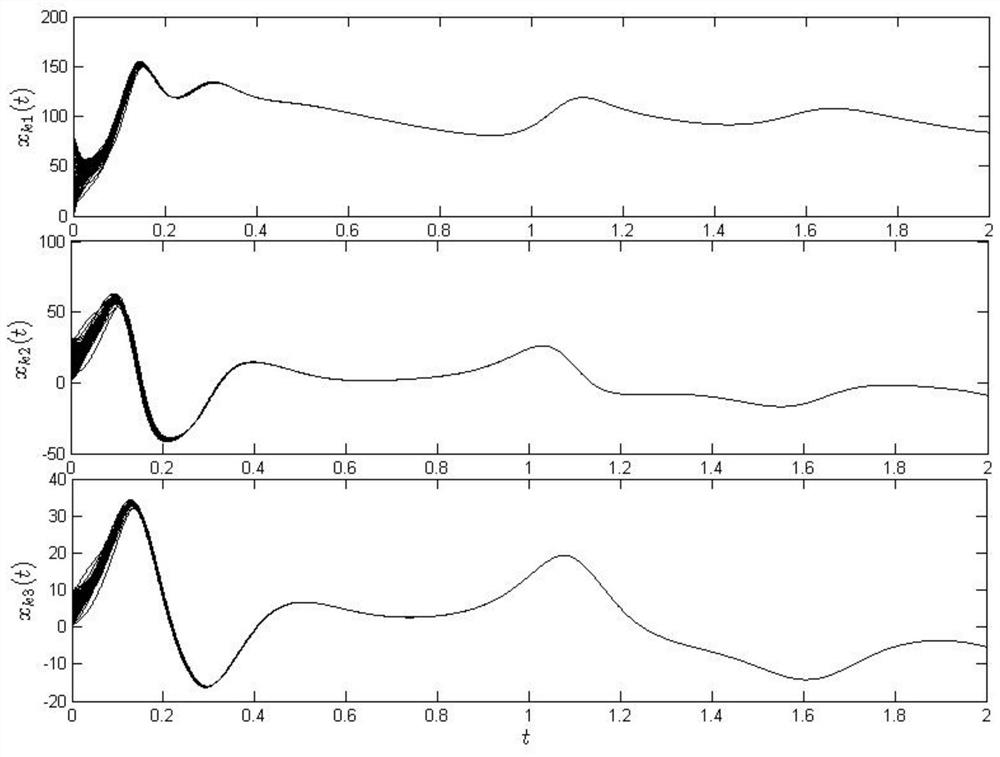

[0048] Randomly choose a small-world network with n=100 nodes. controller and adaptive law The parameter selection of is: coupling strength c=1, inner coupling matrix Γ=diag(1,1,1), and the initial value of the state variable is in the interval (0,80), (0,30) and (0,10) Ran...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com