Application of smxp-58 strain in reducing cellulose content of tobacco stem

A technology of SMXP-58 and cellulose content, applied in the fields of application, tobacco, and processed tobacco, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0021] In order to use the SMXP-58 strain to degrade cellulose in tobacco stems, it is first necessary to prepare the strain into an easy-to-use bacterial agent, and the specific preparation process is as follows.

[0022] (1) Activated strains: put the SMXP-58 strain on the LB plate, and activate it in a biochemical climate chamber at 37°C for 1 day;

[0023] (2) Preparation of seed liquid: Scrape the bacteria cultured in step (1) in the ultra-clean workbench, inoculate in a 18×180 test tube containing 5 mL of liquid LB medium, and place on a shaker at 30°C and 150 rpm Overnight culture;

[0024] (3) Expansion culture: Transfer the seed solution in step (2) to a sterile 250mL Erlenmeyer flask containing 100mL liquid LB medium at the ratio of 1 mL bacterial suspension / 100 ml LB medium (1% volume ratio) medium, 30°C, 150 rpm, cultured to OD 600 = about 2.0;

[0025] (4) Preparation of bacterial agent: Centrifuge the bacterial solution in step (3) at 3600 rpm for 10 minutes, ...

Embodiment 2

[0027] When utilizing the bacterial agent prepared in the embodiment 1 to process the tobacco stem, the concrete steps are:

[0028] Take the cut stems for testing on the silk production line, the parameters of the cut stem samples are: the average thickness is 0.16 mm, the average length is 3.5 mm, and then evenly divided into multiple parts, each 100 g;

[0029] Spray the microbial agent prepared in Example 1 evenly on the surface of the cut stems with a sprayer, and then adjust the moisture content of the cut stems to 25%.

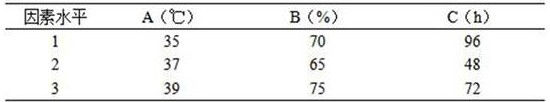

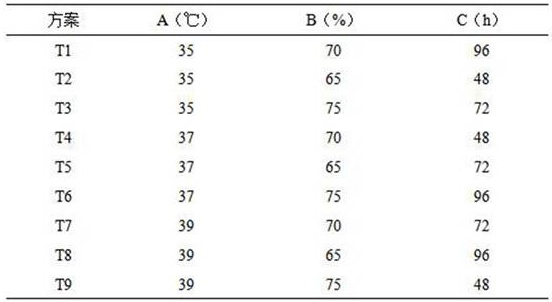

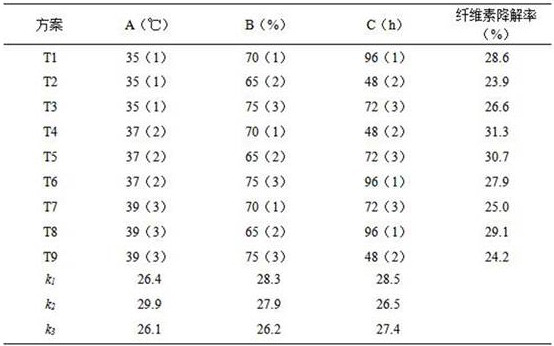

[0030] In order to obtain the optimal action conditions of the bacterial preparation, the temperature, humidity, and time of the bacterial preparation were used as influencing factors respectively, and a 3-factor 3-level orthogonal experimental design was carried out (horizontal factor table (L9(3) 3 )), the specific design is shown in Table 1:

[0031] Table 1 Orthogonal test factor level L 9 (3 3 )

[0032]

[0033] Note: A is the action temper...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com