Preparation method and application of ultra-thin multi-metal nanosheet piling assembly material

A multi-metal, nano-sheet technology, applied in the field of electrocatalysis, can solve the problems of inconvenient material recovery and reuse, and decreased material stability.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0031] Add 100mg of cetyltrimethylammonium chloride, 100mg of polyvinylpyrrolidone, 8mg of palladium acetylacetonate, 10mg of platinum acetylacetonate, and 3-13mg of trichloride into a 25mL polytetrafluoroethylene reactor liner. Ruthenium, 1.35-8.1mg of ferric chloride, 50mg of tungsten hexacarbonyl and 12mL of absolute ethanol. Stir at room temperature at a speed of 600rpm for 30min, put it in an oven, heat up from 30°C to 180°C (heating rate: 5°C / min), and keep at 180°C for 30-90min, then naturally cool to room temperature, and finally wash with ethanol several times And save it in ethanol for later use, and obtain the ultrathin PdPtRu trimetallic nanosheet stack assembly material.

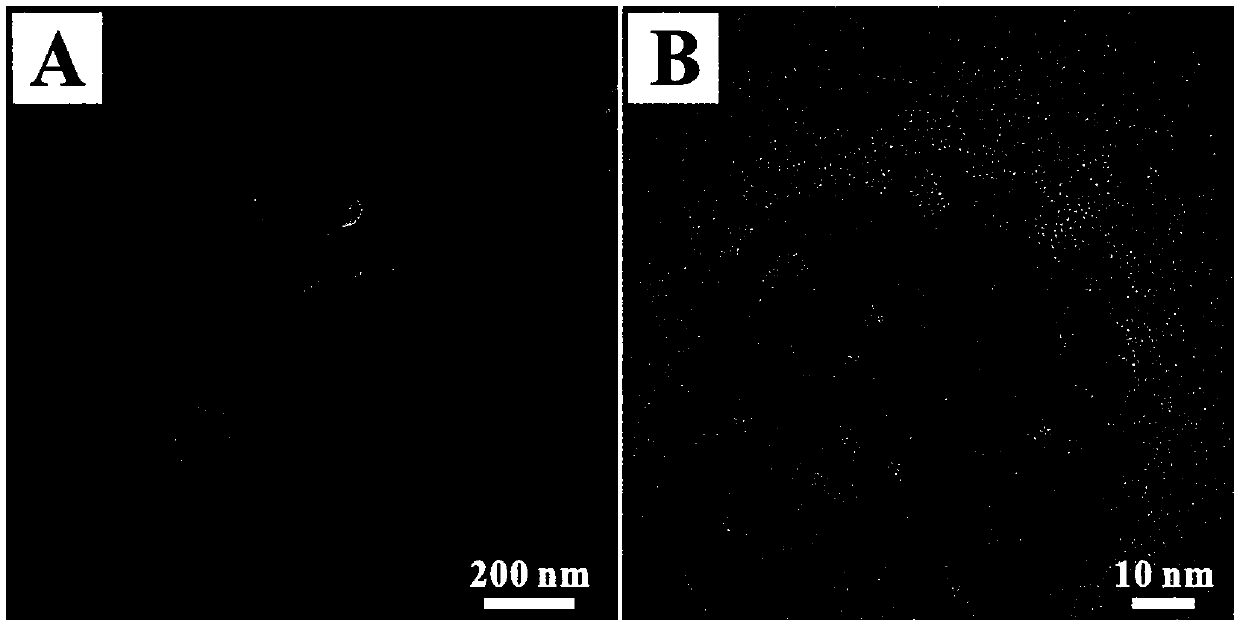

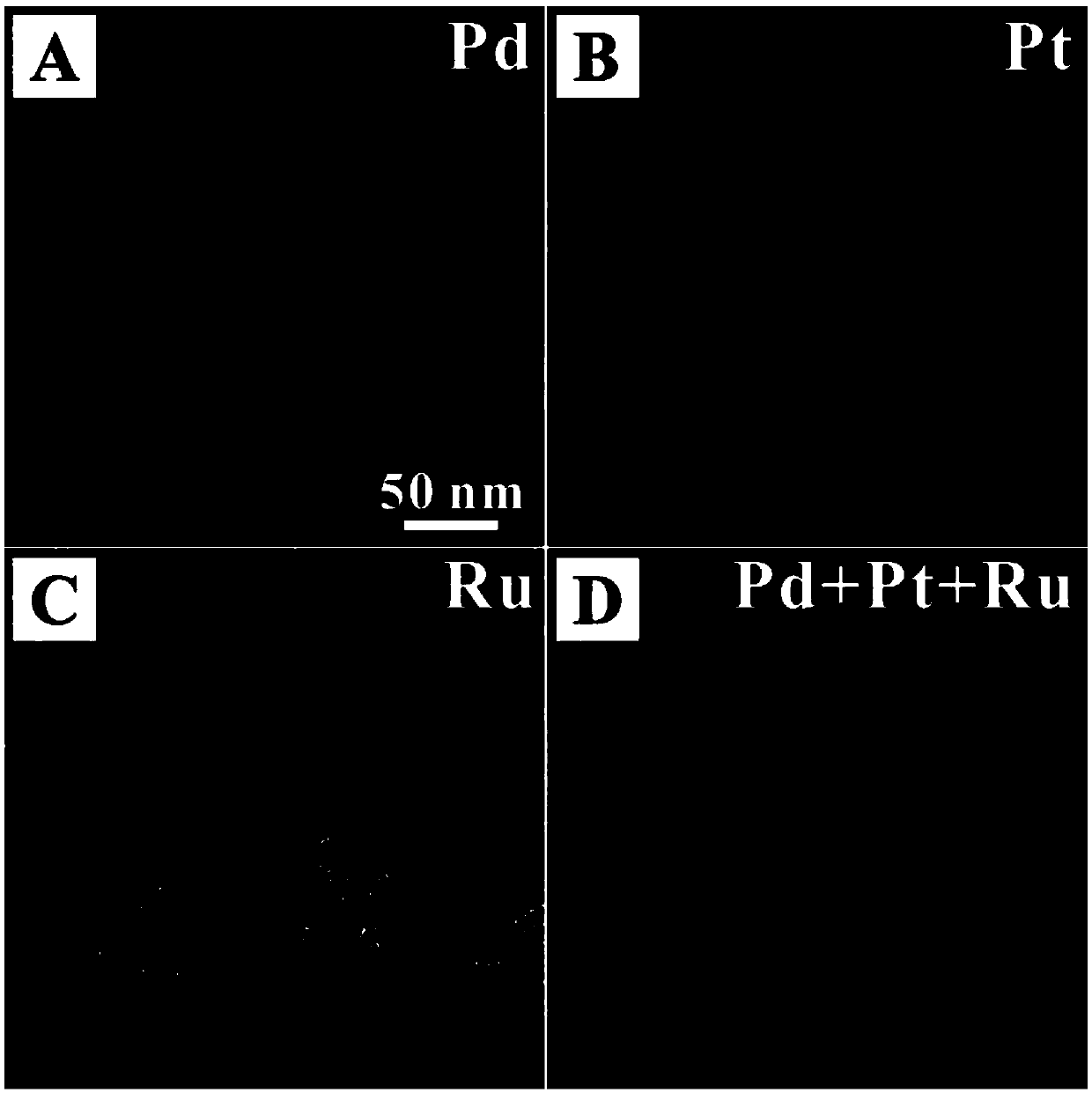

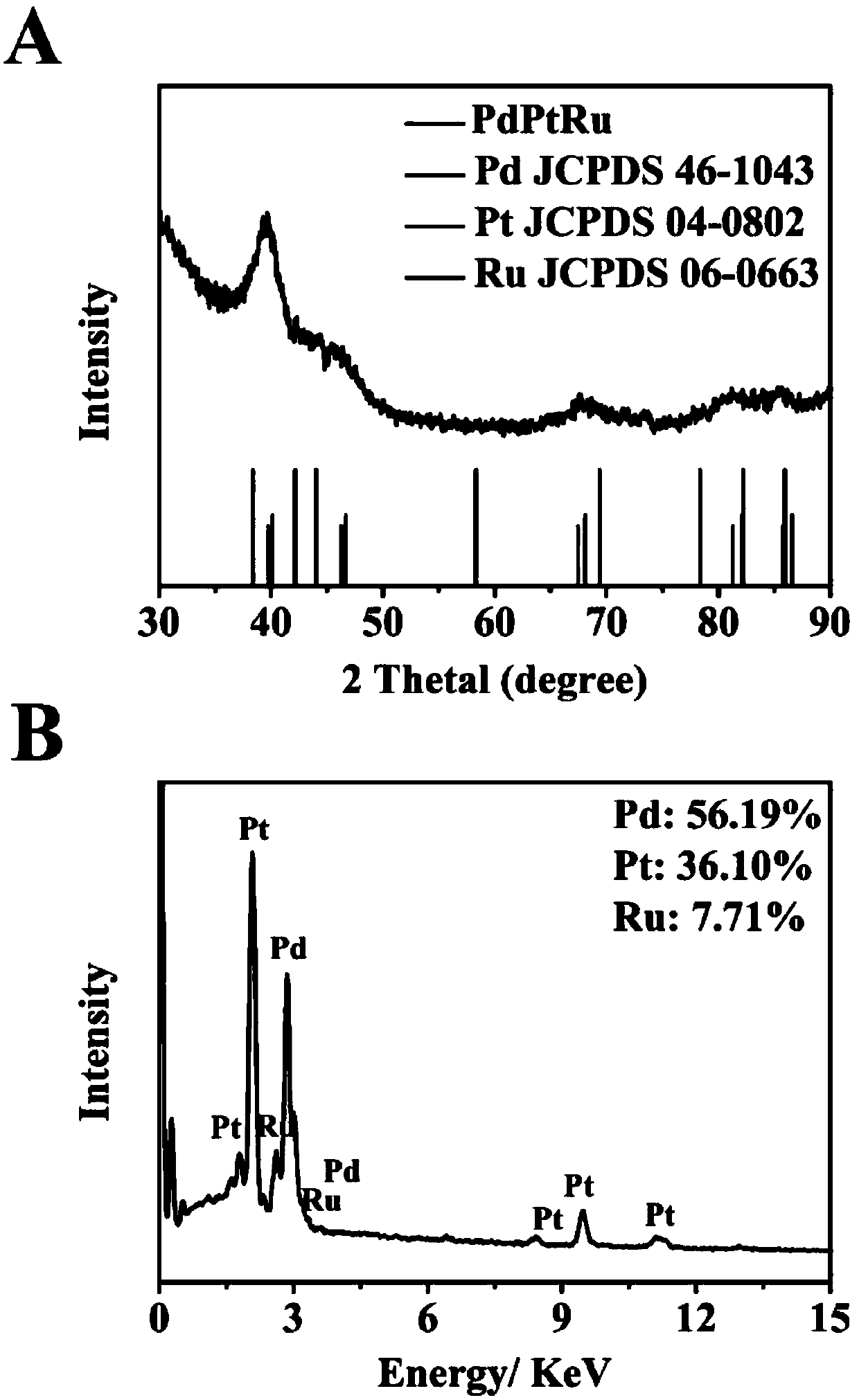

[0032] The ultra-thin PdPtRu three-metal nanosheet stack assembly material was systematically studied on its morphology, composition, and microstructure by modern nanometer testing and analysis techniques such as TEM, HRTEM, and SEM-EDS. TEM, HRTEM ( figure 1 A, B) Characterized as a two-dimen...

Embodiment 2

[0034] In a 25mL polytetrafluoroethylene reactor liner, add 100mg of cetyltrimethylammonium chloride, 100mg of polyvinylpyrrolidone, 8mg of palladium acetylacetonate, 10mg of platinum acetylacetonate, and 8mg of anhydrous chloride Nickel, 1.35-8.1mg of ferric chloride, 50mg of tungsten hexacarbonyl and 12mL of absolute ethanol. Stir at room temperature at a speed of 600rpm for 30min, put it in an oven, heat up from 30°C to 180°C (heating rate: 5°C / min), and keep at 180°C for 30-90min, then naturally cool to room temperature, and finally wash with ethanol several times And save it in ethanol for later use, and obtain the ultrathin PdPtRh trimetallic nanosheet stack assembly material.

[0035] TEM characterization as Figure 4 A, B, Trimetallic PdPtNi nanocrystals with two-dimensional hexagonal ring assembly structure.

Embodiment 3

[0037]In a 25mL polytetrafluoroethylene reactor liner, add 100mg of cetyltrimethylammonium chloride, 100mg of polyvinylpyrrolidone, 8mg of palladium acetylacetonate, 10mg of platinum acetylacetonate, and 13mg of rhodium trichloride , 1.35-8.1mg of ferric chloride, 50mg of tungsten hexacarbonyl and 12mL of absolute ethanol. Stir at room temperature at a speed of 600rpm for 30min, put it in an oven, heat up from 30°C to 180°C (heating rate: 5°C / min), and keep at 180°C for 30-90min, then naturally cool to room temperature, and finally wash with ethanol several times And save it in ethanol for later use, and obtain the ultrathin PdPtRh trimetallic nanosheet stack assembly material.

[0038] TEM characterization as Figure 5 A, B, Trimetallic PdPtRh nanocrystals are hexagonal sheet-assembled structures.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com