Flotation method for reducing tin content of pyrite

A technology of pyrite and flotation, which is applied in flotation, solid separation, grain processing, etc., can solve the problem of high tin content in sulfur concentrate, and achieve the effects of low tin content, non-toxic and low price

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

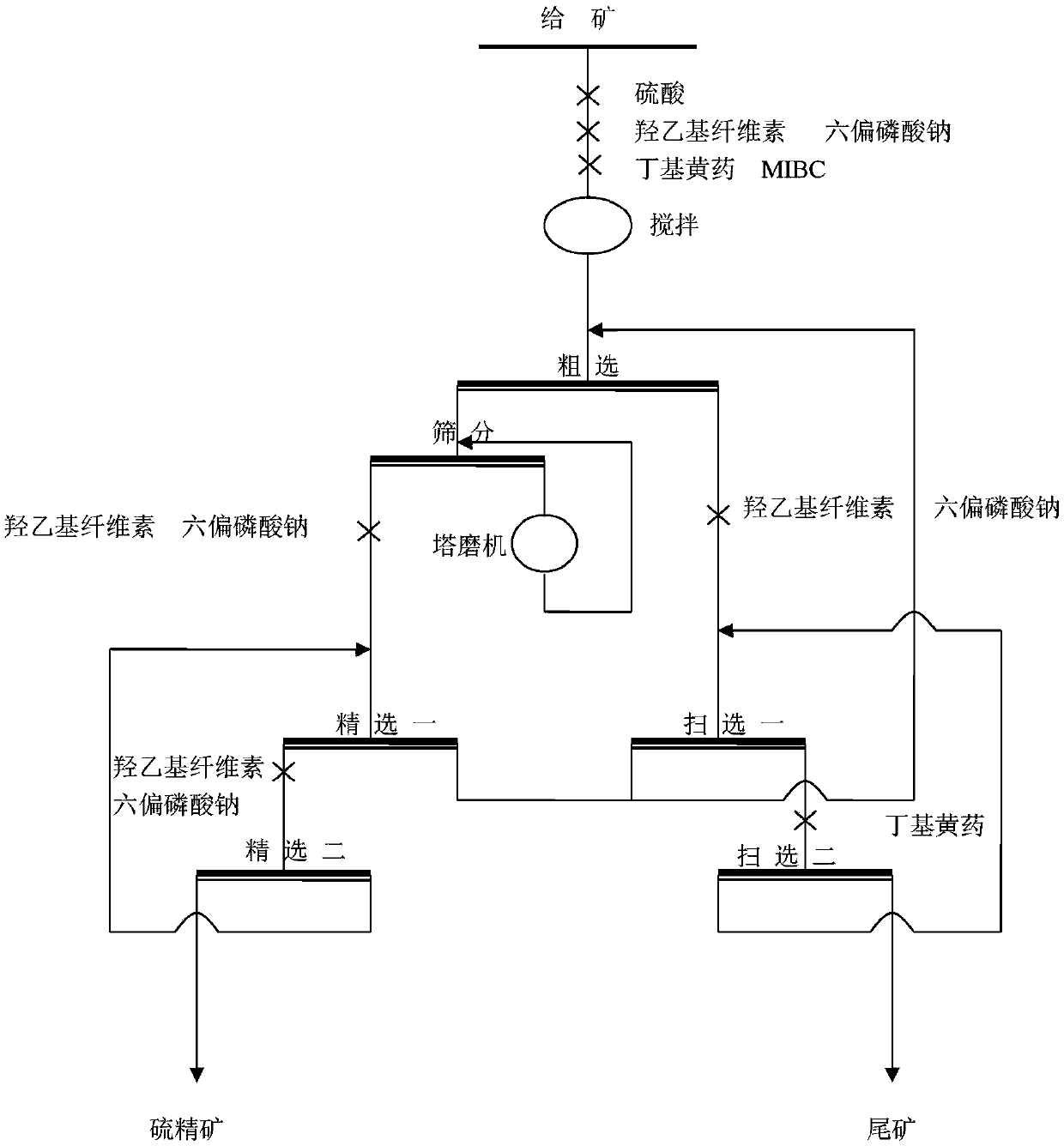

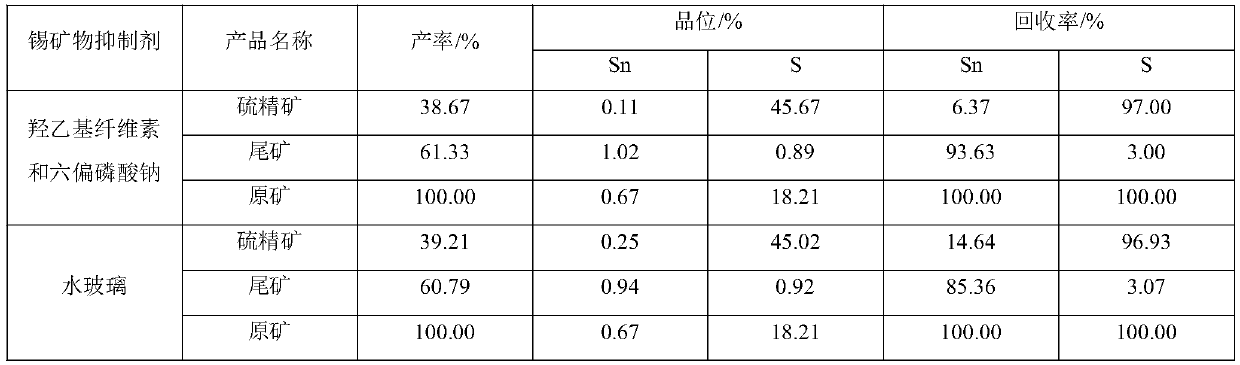

[0032] A certain lead-zinc flotation tailings contains sulfur and tin, and the ore contains 0.67% tin and 18.21% sulfur. figure 1 Shown technological process, concrete technological parameter is as follows:

[0033] Adjustment of tin-containing pyrite ore slurry: in the mixing equipment, the mass ratio of liquid to solid is 1.5:1 to stir and adjust the slurry, add sulfuric acid, the dosage is 1000g / t, the pH value is kept at 5-6, the collector butyl xanthate is 120g / t and Foaming agent methyl isobutyl carbinol 20g / t, then add cassiterite inhibitor hydroxyethyl cellulose and sodium hexametaphosphate mixed agent 500g / t. The mixing time is 10 minutes.

[0034] Flotation separation of sulfide ores and tin minerals: the technological process is one roughing and two sweeping. The obtained coarse ore concentrate is ground again, and after two rounds of beneficiation, the tin-containing low-sulfur concentrate is obtained.

[0035] The coarse concentrate products in the roughing ope...

Embodiment 2

[0045] The raw ore contains 1.21% tin and 12.43% sulfur. figure 1 Shown technological process, concrete technological parameter is as follows:

[0046] Adjustment of tin-containing pyrite ore slurry: in the mixing equipment, the mass ratio of liquid to solid is 1.5:1 to stir and adjust the slurry, add sulfuric acid, the dosage is 800g / t, the pH value is kept at 6, the collector butyl xanthate is 120g / t and foaming Methyl isobutyl carbinol 20g / t, then add cassiterite inhibitor hydroxyethyl cellulose and sodium hexametaphosphate mixed agent 400g / t. The mixing time is 10 minutes.

[0047] Flotation separation of sulfide ores and tin minerals: the technological process is one roughing and two sweeping. The obtained coarse ore concentrate is ground again, and after two rounds of beneficiation, the tin-containing low-sulfur concentrate is obtained.

[0048] The coarse concentrate products in the roughing operation are graded and then ground. The grinding equipment adopts a tower ...

Embodiment 3

[0059] The raw ore contains 2.78% tin and 21.45% sulfur. figure 1 Shown technological process, concrete technological parameter is as follows:

[0060] Adjustment of tin-containing pyrite ore slurry: in the mixing equipment, the mass ratio of liquid to solid is 1.5:1 to stir and adjust the slurry, add sulfuric acid, the dosage is 1000g / t, the pH value is kept at 5.5, the collector butyl xanthate is 150g / t and foaming Add 30g / t of methyl isobutyl carbinol, and then add cassiterite inhibitor hydroxyethyl cellulose and sodium hexametaphosphate mixed agent 500g / t. The mixing time is 10 minutes.

[0061] Flotation separation of sulfide ores and tin minerals: the technological process is one roughing and two sweeping. The obtained coarse ore concentrate is ground again, and after two rounds of beneficiation, the tin-containing low-sulfur concentrate is obtained.

[0062] The coarse concentrate products in the roughing operation are graded and then ground. The grinding equipment a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com