Bottle recycling cleaning line for small bottles of canned fissure spring water

An assembly line and fissure technology, applied in the direction of cleaning hollow objects, cleaning methods and utensils, lighting and heating equipment, etc., can solve the problems of high labor intensity of operators, secondary pollution of the bottle body, and increased cleaning burden, etc. Low labor intensity and high cleaning efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

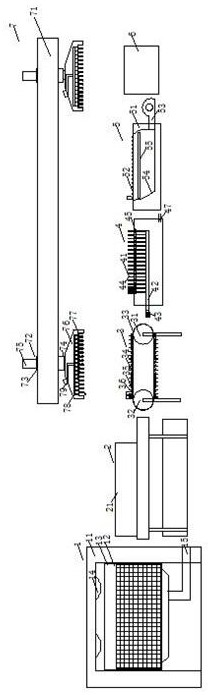

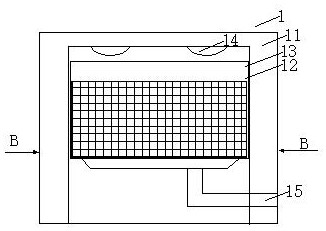

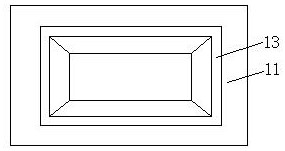

[0032] In order to enable those of ordinary skill in the art to better understand the technical solution of the present invention, the following in conjunction with the attached Figure 1-11 The technical scheme of the present invention is described further with embodiment.

[0033] In order to solve the problems of low cleaning efficiency and high labor intensity in the bottle recovery and cleaning process of filling deep spring water in small bottles in the prior art, the present invention designs a bottle recovery and cleaning assembly line for filling cracked deep spring water in small bottles, including bottle body cleaning Equipment 1, transmission platform 2, plug-in equipment 3, internal cleaning equipment 4, internal drying equipment 5, ultraviolet disinfection box 6 and clamping transportation equipment 7, the clamping transportation equipment 7 is set in the plug-in equipment 3, internal cleaning The space above the equipment 4, the internal drying equipment 5 and t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com