Method for achieving environmental protection and high yield of composite modified carbon nanotubes and products

A carbon nanotube, high-yield technology, applied in the direction of carbon nanotubes, nanocarbons, chemical instruments and methods, etc., can solve the problems of ineffective combination of carbon tubes and other materials, reduced conductivity and surface functionality of carbon tubes, and surface activity It is difficult to remove the agent and other problems, so as to achieve good oxidation modification effect, improve safety and environmental protection, and achieve the effect of low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0053] Such as figure 1 As shown, a method for modifying carbon nanotubes to improve the yield in an environment-friendly manner, the specific steps are as follows:

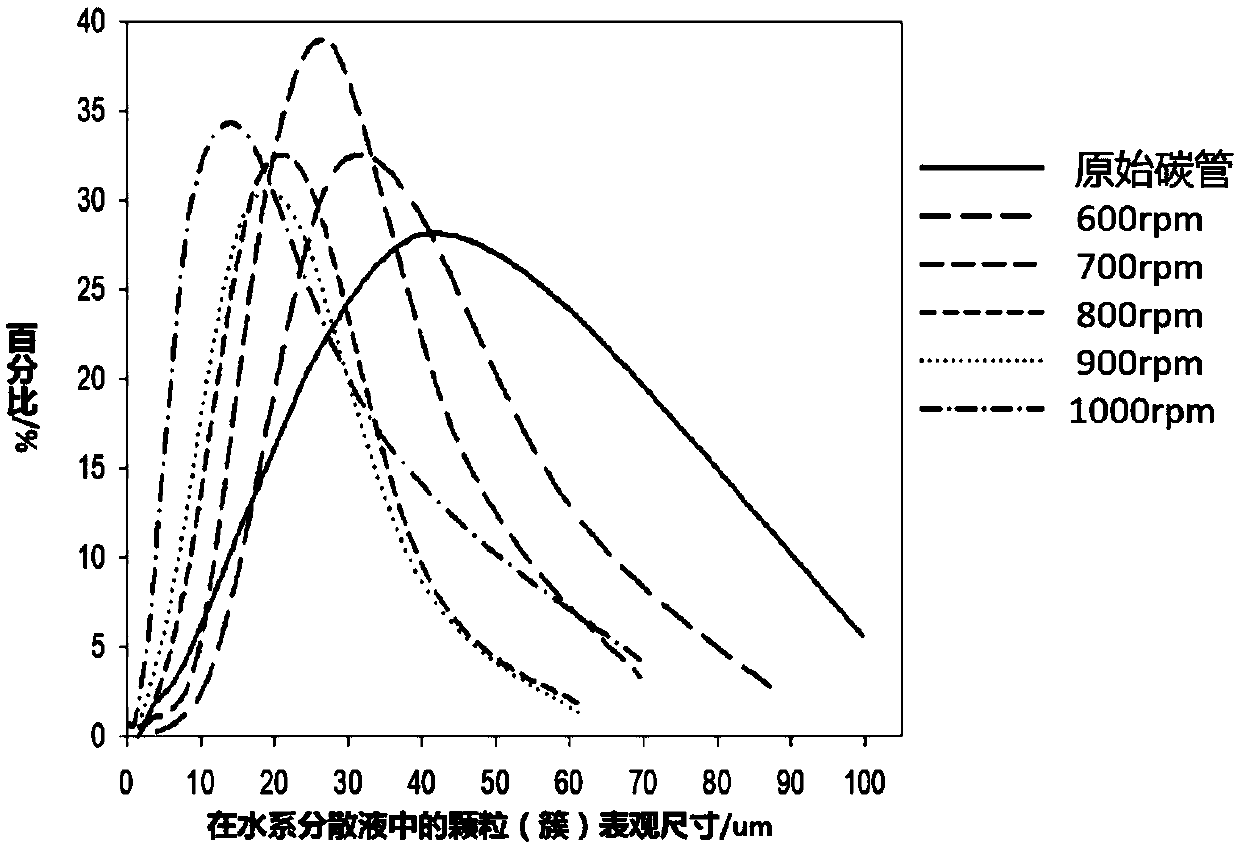

[0054] Step 1 (pre-interruption treatment): Add 150g of alumina balls, 1g of carbon tubes, and 15mL of deionized water to two identical ball milling jars; place the two ball milling jars symmetrically Set at 600rpm / h, and set the time for 3 hours; after ball milling for 3 hours, pour the mixture in the tank onto a sieve with a suitable mesh, rinse with deionized water, and separate the carbon tube and alumina ball; The mixture of tubes and water is placed on a G4 sand core funnel, and the carbon tubes and water are separated using a vacuum filtration device. The carbon tubes obtained in the preceding steps were dried in a drying oven at 50° C. for 24 hours, and the treated carbon tube powder was obtained after grinding.

[0055] Step 2 (airtight container reaction): Weigh 80 mg of ball-milled carbon tubes and p...

Embodiment 2

[0062] A method for modifying carbon nanotubes to improve yield in an environment-friendly way, the specific steps are as follows:

[0063] Step 1 (pre-interruption treatment): place 1g of carbon tubes and 30mL of deionized water in a beaker, place the above beaker in an ultrasonic water tank, and perform ultrasonication for 1 hour with an ultrasonic power of 600W; fix the beaker in the cavity of the cell disruptor , set the ultrasonic power to 500W, and set the time to 12min; after the end, use a G4 sand core funnel to separate the treated carbon tubes from water, and clean them with deionized water; place the carbon tubes obtained in the previous steps in a drying oven at 50°C Drying in medium temperature for 12 hours, grinding and pulverizing to obtain treated carbon tubes.

[0064] Step 2 (airtight container reaction): Weigh 120 mg of the above-mentioned pre-interrupted carbon tube and place it in a 25 mL beaker, slowly add 9 mL of sulfuric acid (7 mL of concentrated sulfu...

Embodiment 3

[0068] A method for modifying carbon nanotubes to improve yield in an environment-friendly way, the specific steps are as follows:

[0069] Step 1 (pre-interruption treatment): Place 500mg of carbon tubes and 20mL of deionized water in a beaker; place the above beaker in an ultrasonic tank, ultrasonicate for 0.5 hours, with an ultrasonic power of 600W; place and fix the beaker on the probe of the emulsification machine bottom, so that the probe can penetrate into the mixture but not touch the bottom of the beaker; set the power of the emulsifier to 1000W, and set the time to 3min; after the experiment, use the G4 sand core funnel to separate the treated carbon tube from the water, and Washing with water; drying the carbon tubes obtained in the above steps in a drying oven at 50° C. for 12 hours, and then grinding and pulverizing to obtain the treated carbon tubes.

[0070] Step 2 (airtight container reaction): Weigh 180 mg of pre-interrupted carbon tubes and place them in a 25...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com