Preparation method of large-particle-size indium oxide

An indium oxide, large particle size technology, applied in chemical instruments and methods, inorganic chemistry, gallium/indium/thallium compounds, etc., can solve the problems of small particle size of indium oxide particles, large specific surface area, increased complexity and difficulty, etc. , to achieve the effect of easy enlargement, simplified process flow and easy operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

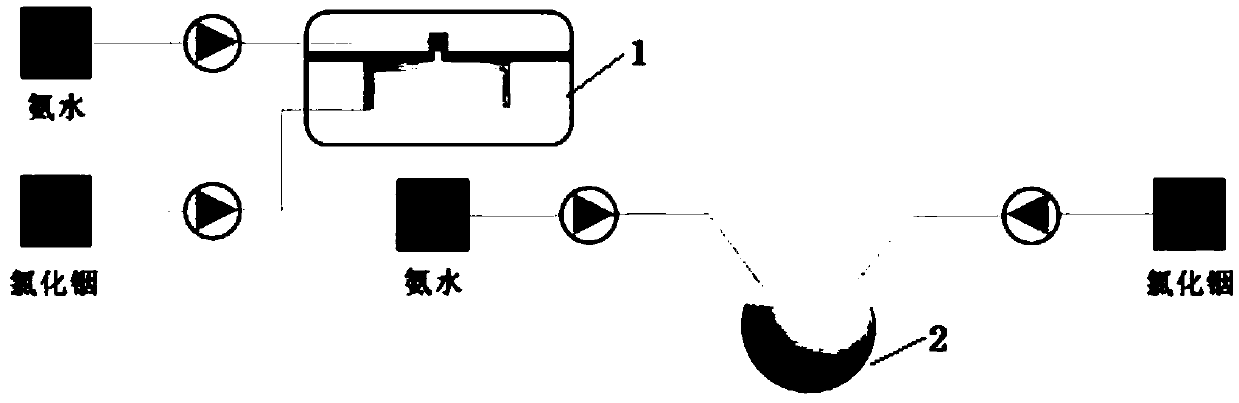

[0023] The invention provides a preparation method of large particle size indium oxide, comprising the following steps:

[0024] (1) The indium chloride solution and the ammonia solution are respectively flowed into the membrane microreactor to carry out a co-precipitation reaction to obtain a seed solution;

[0025] (2) taking out the described seed crystal liquid, adding indium chloride solution and ammonia aqueous solution to the seed crystal liquid under heating conditions in parallel to obtain a reaction solution;

[0026] (3) centrifuging, washing and drying the reaction solution successively to obtain precursor powder;

[0027] (4) calcining the precursor powder to obtain large particle size indium oxide; the particle size of the large particle size indium oxide is ≥30 nm.

[0028] In the present invention, the indium chloride solution and the ammonia solution are respectively flowed into the membrane microreactor to carry out co-precipitation reaction to obtain the se...

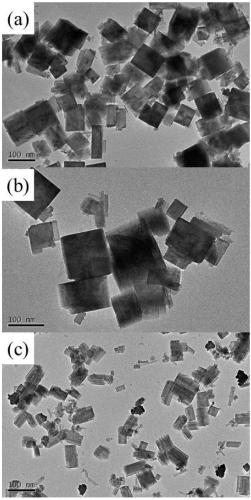

Embodiment 1

[0036] (1) prepare an indium chloride solution with a concentration of 10 g / L, and make it flow into the microreactor at a flow rate of 5 mL / min;

[0037] (2) preparing the ammonia solution with a concentration of 1 mol / L, and making it flow into the microreactor at a flow rate of 5 mL / min, realizing rapid mixing of the two phases by shearing the dispersed phase, and carrying out a co-precipitation reaction;

[0038] (3) take 20mL of reacted slurry and flow into the three-necked flask to continue stirring, wherein the three-necked flask is placed in a water bath of 70°C;

[0039] (4) add 10 g / L of indium chloride solution and 1 mol / L of ammonia aqueous solution dropwise to a total of 80 mL at a flow rate of 1 mL / min;

[0040] (5) centrifugation of the mixed solution in the stirred tank, the obtained solid is washed twice with deionized water and ethanol, respectively, and is dried to obtain the precursor powder;

[0041] (6) The precursor powder is placed in a muffle furnace, a...

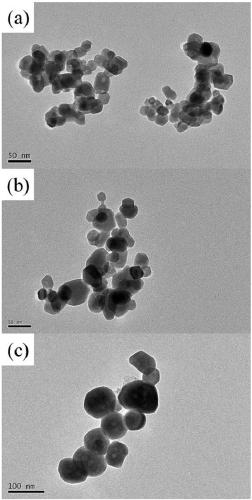

Embodiment 2

[0044] (1) prepare an indium chloride solution with a concentration of 50 g / L, and make it flow into the microreactor at a flow rate of 5 mL / min;

[0045] (2) The ammonia aqueous solution with a concentration of 2 mol / L is prepared, and it flows into the microreactor at a flow rate of 5 mL / min, and the two phases are rapidly mixed by shearing the dispersed phase, and a co-precipitation reaction is carried out;

[0046] (3) take 5mL of reacted slurry and flow into the three-necked flask to continue stirring, wherein the three-necked flask is placed in a water bath of 50°C;

[0047] (4) 100mL of indium chloride solution of 10g / L and ammonia solution of 1mol / L were added dropwise in parallel at a flow rate of 1mL / min;

[0048] (5) centrifugation of the mixed solution in the stirred tank, the obtained solid is washed twice with deionized water and ethanol, respectively, and is dried to obtain the precursor powder;

[0049] (6) The precursor powder is placed in a muffle furnace, a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com