Self-healing ceramic matrix composite and low-temperature rapid preparation method thereof

A composite material and ceramic-based technology, which is applied in the field of rapid preparation of ceramic-based composite materials and mud-assisted precursor dipping cracking method at low temperature, which can solve the problems of long composite material preparation period, formation of cracks and pores in the matrix, and great influence on the fiber system and other problems to achieve the effect of shortening the preparation cycle, reducing erosion and reducing costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

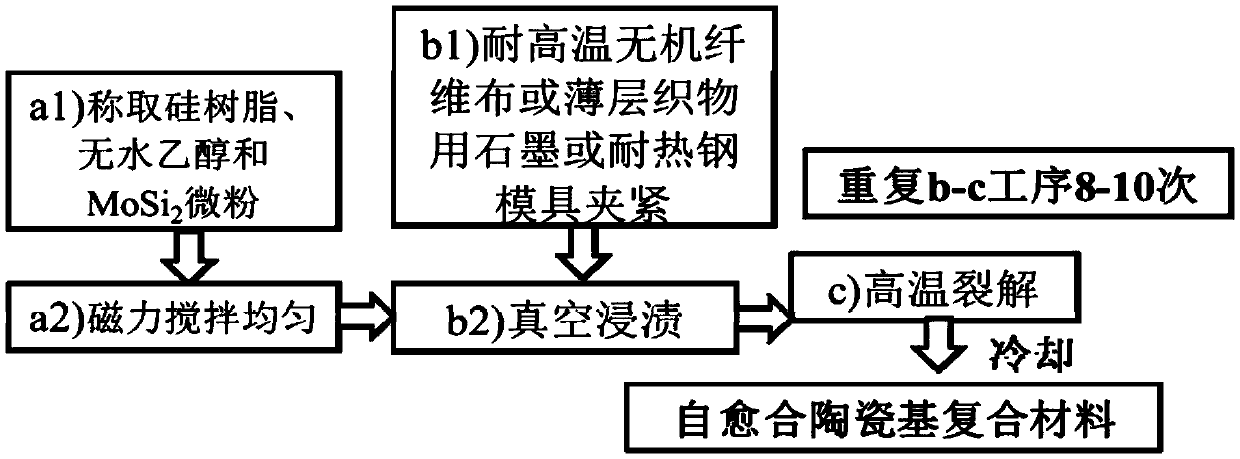

[0036] a C f / SiOC-MoSi 2 Matrix composite materials, the preparation method of which is as follows figure 1 As shown, the following steps are included: (1) 8 layers of T300 carbon fiber cloth with a thickness of 0.28 mm are laid flat, and then stitched. The fiber used for stitching is commercially available common T300 carbon fiber. The distance between two sutures is 5mm; (2) Weigh silicone resin, MoSi 2 Micropowder and absolute alcohol, including silicone resin, absolute alcohol and MoSi 2 The weighing ratio of the micropowder is 1:1:5 by mass, and the MoSi 2 Put the micropowder and silicone resin into absolute ethanol, and stir for 4 hours by magnetic force to form a silicone resin solution doped with MoSi 2 Suspension of micropowder; (3) Clamp the T300 carbon fiber cloth obtained in step (1) with a graphite mold, place it in a vacuum container, vacuum inhale the suspension obtained in step (2), and soak for 8h; (4) Place the T300 carbon fibers impregnated in step (3...

Embodiment 2

[0041] A SiC f / SiOC-MoSi 2 Composite materials, methods for their preparation, such as figure 1 As shown, the following steps are included: (1) 8 layers of second-generation SiC fiber cloth produced by the National University of Defense Technology with a thickness of 0.23 mm are laid flat, and then stitched. The fiber used for stitching is the second-generation SiC fiber. In order to obtain a higher Excellent mechanical properties, the distance between every two sutures is designed to be 10mm; (2) Weigh silicone resin, MoSi 2 Micropowder and absolute alcohol, including silicone resin, absolute alcohol and MoSi 2 The weighing ratio of the micropowder is 1:2:1 by mass, and the MoSi 2 Put the micropowder and silicone resin into absolute ethanol, and stir it by magnetic force for 8 hours to form a silicone resin solution doped with MoSi 2 Suspension of micropowder; (3) Clamp the SiC fiber cloth obtained in step (1) with a heat-resistant steel mold, place it in a vacuum conta...

Embodiment 3

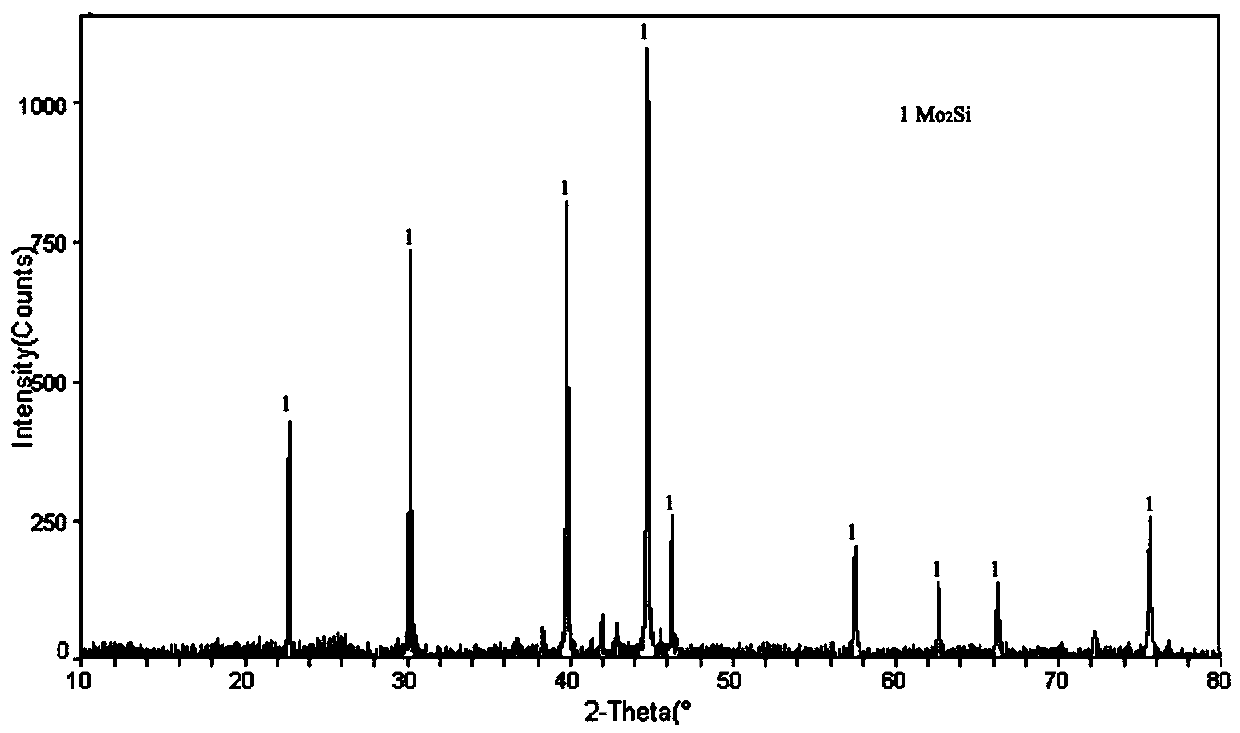

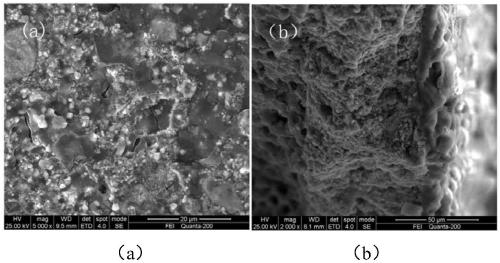

[0047] To the obtained C of embodiment 1 f / SiOC-MoSi 2 The base composite material was subjected to oxidation treatment at 1200° C., and the oxidation time was 2 hours. The preparation method of the composite material was the same as that in Example 1. image 3 It is the surface and section SEM diagram of the self-healing ceramic matrix composite material obtained in Example 1 of the present invention, wherein (a) is the surface SEM; (b) is the section SEM; Figure 4 It is the SEM image of the surface and section of the self-healing ceramic matrix composite material obtained in Example 1 of the present invention after being oxidized at 1200 ° C for 2 hours, wherein (a) is the surface SEM; (b) is the section SEM, from figure 2 (a) and (b) with image 3 Comparing (a) and (b), it can be seen that MoSi 2 It is oxidized at a temperature of 1200°C to form a fluid glass phase, which realizes the sealing of surface cracks and matrix cracks. The porosity of the material decreases fr...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com