Method for rapidly degrading polylactic acid

A rapid degradation, polylactic acid technology, applied in the direction of plastic recycling, recycling technology, etc., can solve the problems of non-degradable or slow-degradable general-purpose plastics, long-term removal or degradation, uncontrollable degradation speed, etc., to achieve accelerated degradation, Ease of implementation and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

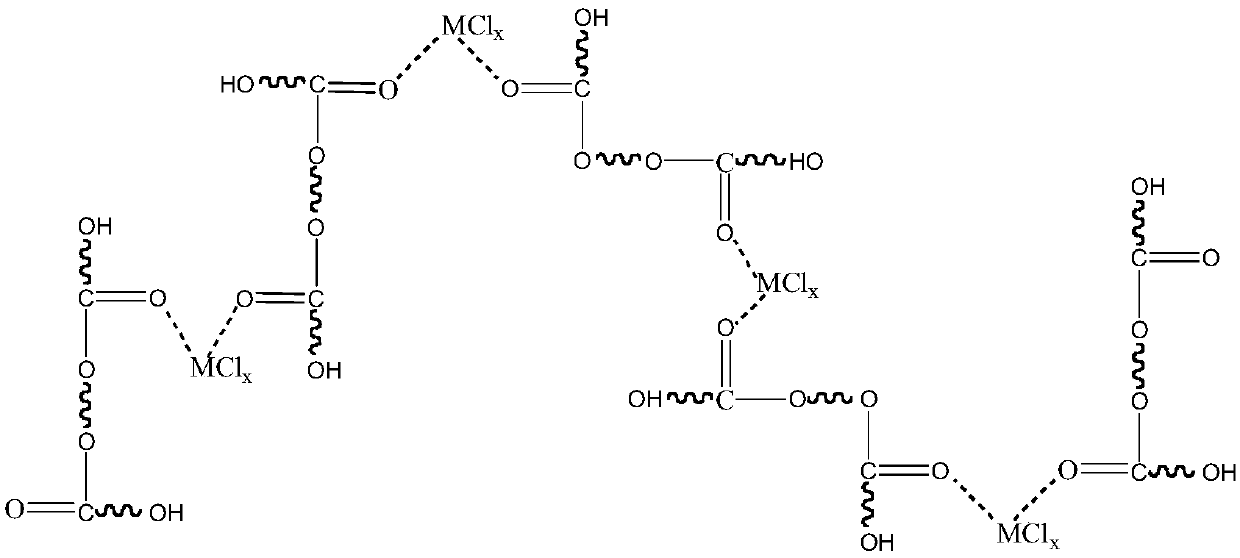

Method used

Image

Examples

Embodiment 1

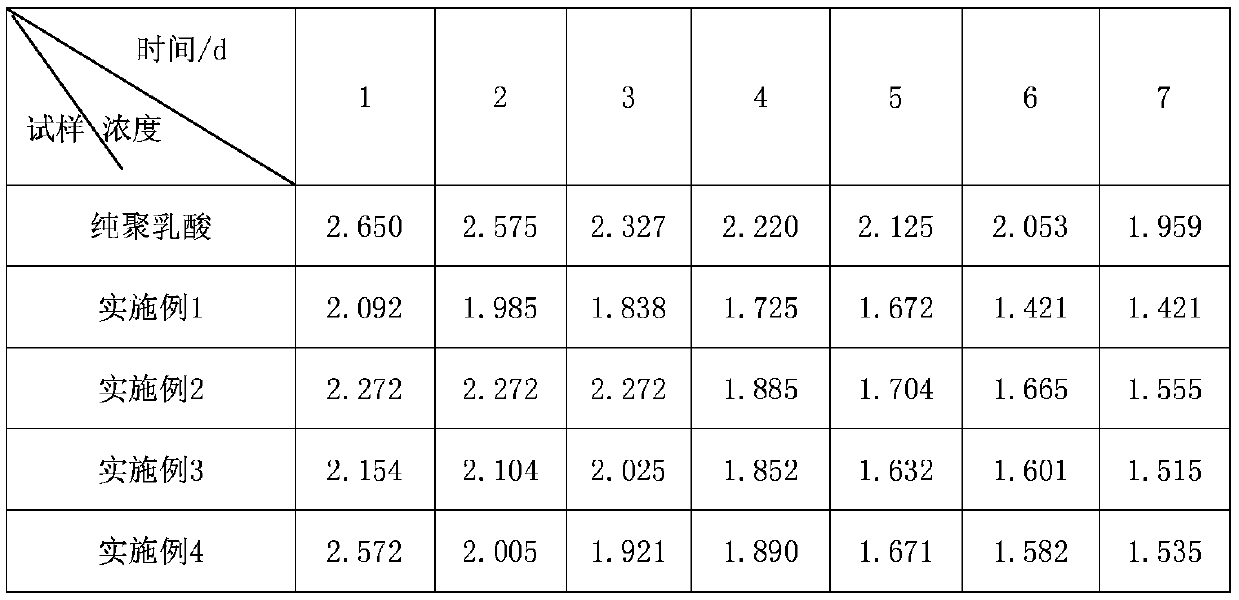

[0018] Embodiment 1: The preparation of rapidly degrading polylactic acid, get a certain amount of polylactic acid (L-polylactic acid pellets, melt index is 5.6g / 10min, 190 ℃) and ferric chloride, dry 12h in the vacuum oven of 60 ℃ Finally, weigh 100g of dry polylactic acid and pre-mix 3g of ferric chloride; then add the mixture into the material chamber of the internal mixer, and set the temperature as: 185°C in the first zone, 185°C in the second zone, 190°C in the third zone, and the rotor Rotational speed: 80 rpm, after 10 minutes of reaction, the material is discharged, and crushed in a powerful crusher to obtain a polylactic acid modified material.

Embodiment 2

[0019] Embodiment 2: the preparation of rapidly degrading polylactic acid, get a certain amount of polylactic acid (L-polylactic acid pellets, melt index is 5.6g / 10min, 190 ℃) and zinc chloride, dry 12h in the vacuum oven of 60 ℃ Then take 100g of dry polylactic acid and pre-mix 2g of zinc chloride (2 parts). Then add the mixture into the material chamber of the internal mixer, set the temperature as: 185°C in the first zone, 185°C in the second zone, and 190°C in the third zone, the rotor speed: 80 rpm, and leave after 2 minutes of reaction. Crushing in the machine to obtain polylactic acid modified materials.

Embodiment 3

[0020] Embodiment 3: the preparation of rapidly degrading polylactic acid, get a certain amount of polylactic acid (L-polylactic acid pellets, melt index is 5.6g / 10min, 190 DEG C) and calcium chloride, dry 12h in the vacuum oven of 60 DEG C Then weigh 100g of dry polylactic acid and premix 3g (3 parts) of calcium chloride. Then the mixture was added to the material chamber of the internal mixer, the temperature was set as: 185°C in the first zone, 185°C in the second zone, 190°C in the third zone, the rotor speed: 80 rpm, and the material was discharged after 7 minutes of reaction. Crushing in a powerful crusher to obtain polylactic acid modified materials.

PUM

| Property | Measurement | Unit |

|---|---|---|

| melt flow index | aaaaa | aaaaa |

| melt flow index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com