Early strength agent for cementation of oil wells in low-temperature mining area and preparation method thereof

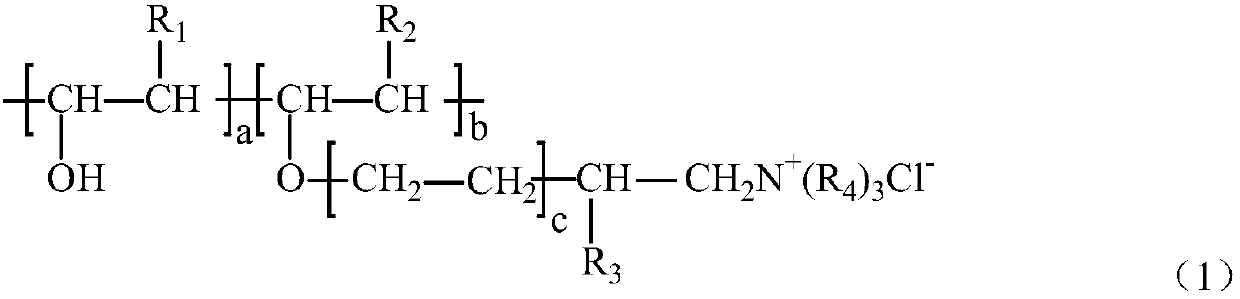

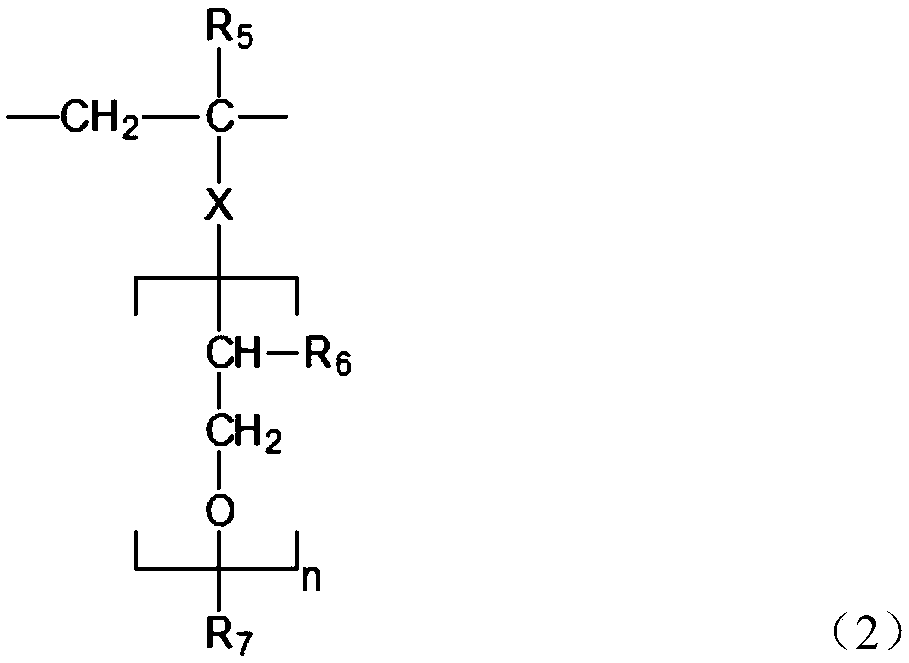

A technology of oil well cementing and early strength agent, which is applied in the direction of chemical instruments and methods, drilling compositions, etc., can solve the problems of casing corrosion, cement slurry loss of fluidity, false setting, etc., and reduce the crystallization nucleation potential barrier, promote the hydration reaction rate of cement, and improve the effect of early strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0035] Take by weighing 38.25g of calcium chloride and 50.15g of water to configure calcium chloride aqueous solution, weigh 43.74g of potassium silicate and 44.26g of water to configure potassium silicate solution, weigh 13.28g of anionic dispersant, 11.53g of cationic dispersant and 158.2g of water is used to configure the aqueous solution of the composite dispersant. The composite dispersant solution was introduced into a three-necked flask, the temperature was set at 15°C, and the dispersant solution was stirred evenly. Under the condition of keeping stirring, the calcium chloride aqueous solution and the potassium silicate aqueous solution are added dropwise at the same time, and the dropping rate is adjusted so that the dropping time is controlled at about 1 hour. Continue stirring for 1 h after the dropwise addition, and then slowly cool down to room temperature to obtain the early strengthening agent HA-1.

Embodiment 2

[0037] Weigh 54.85g of calcium nitrate and 55.29g of water to configure calcium nitrate aqueous solution, weigh 53.74g of water glass and 44.26g of water to configure water glass solution, weigh 10.28g of anionic dispersant, 13.53g of cationic dispersant and 141.5g of water to configure Composite dispersant aqueous solution. The composite dispersant solution was introduced into a three-necked flask, the temperature was set at 15°C, and the dispersant solution was stirred evenly. Under the condition of keeping stirring, the calcium chloride aqueous solution and the potassium silicate aqueous solution are added dropwise at the same time, and the dropping rate is adjusted so that the dropping time is controlled at about 2 hours. Continue to stir for 4 hours after the dropwise addition, and then slowly cool down to room temperature to obtain the early strengthening agent HA-2.

Embodiment 3

[0039] Weigh 44.85g of calcium formate and 53.57g of water to configure calcium formate aqueous solution, weigh 48.36g of potassium metasilicate and 43.78g of water to configure potassium metasilicate solution, weigh 17.65g of anionic dispersant, 14.19g of cationic dispersant and 133.5g of water is used to configure the aqueous solution of the composite dispersant. The composite dispersant solution was introduced into a three-necked flask, the temperature was set at 15°C, and the dispersant solution was stirred evenly. Under the condition of keeping stirring, the calcium chloride aqueous solution and the potassium silicate aqueous solution are added dropwise at the same time, and the dropping rate is adjusted so that the dropping time is controlled at about 7 hours. Continue to stir for 3 hours after the dropwise addition, and then slowly cool down to room temperature to obtain the early strengthening agent HA-3.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com