High-strength wear-resistant flame-retardant polypropylene and preparation method thereof

A flame-retardant polypropylene and high-strength technology, applied in the field of polypropylene, can solve the problems of low wear resistance and low strength of flame-retardant polypropylene, achieve good heat resistance, promote crystallization, and increase strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

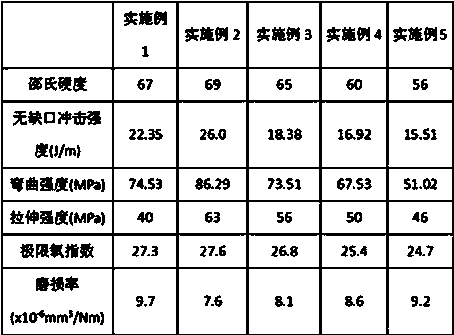

Examples

Embodiment 1

[0028] A high-strength wear-resistant and flame-retardant polypropylene, consisting of 49 parts of polypropylene matrix, 18.2 parts of modified glass fiber with a length of 2mm, 7.8 parts of modified hollow glass microspheres, 1 part of cubic boron nitride, and 7.41 parts of nano-alumina , 12.35 parts of nitrogen-phosphorus flame retardant with a particle size of 3-15 μm, 1.24 parts of white carbon black, 1 part of phosphite antioxidant and 2 parts of dimethyl silicone oil; among them, the modified glass fiber is modified by KH550 Modified glass microspheres are mixed with rare earth modifier and hollow glass microspheres at a weight ratio of 3:100.

[0029] The method for preparing high-strength wear-resistant and flame-retardant polypropylene comprises the following steps: step 1, take 20ml of KH550, and then dissolve it in 980ml of ethanol to make a volume concentration of 2% KH550 / ethanol solution, then weigh 300g of glass fibers, soaked in KH550 / ethanol solution for 12 ho...

Embodiment 2

[0036] A high-strength wear-resistant and flame-retardant polypropylene, consisting of 46 parts of polypropylene matrix, 14.7 parts of modified glass fiber with a length of 2mm, 6.3 parts of modified hollow glass microspheres, 4 parts of cubic boron nitride, and 7.41 parts of nano-alumina , 12.35 parts of nitrogen-phosphorus flame retardant with a particle size of 3-15 μm, 1.24 parts of white carbon black, 3 parts of phosphite antioxidant and 5 parts of dimethyl silicone oil; among them, the modified glass fiber is modified by KH550 Modified glass microspheres are mixed with rare earth modifier and hollow glass microspheres at a weight ratio of 3:100.

[0037] For the preparation method of high-strength wear-resistant and flame-retardant polypropylene, refer to the preparation steps of Example 1.

Embodiment 3

[0039] A high-strength wear-resistant and flame-retardant polypropylene, consisting of 55 parts of polypropylene matrix, 14 parts of modified glass fiber with a length of 2mm, 6 parts of modified hollow glass microspheres, 2 parts of cubic boron nitride, and 6.35 parts of nano-alumina , 10.59 parts of nitrogen-phosphorus flame retardant with a particle size of 3-15 μm, 1.06 parts of white carbon black, 1 part of phosphite antioxidant and 4 parts of dimethyl silicone oil; among them, the modified glass fiber is modified by KH550 Modified glass microspheres are mixed with rare earth modifier and hollow glass microspheres at a weight ratio of 3:100.

[0040] The preparation method of high-strength wear-resistant and flame-retardant polypropylene, the specific steps are: step 1, take 20ml of KH550, then dissolve it in 980ml of ethanol to make a KH550 / ethanol solution with a volume concentration of 2%, and then weigh 300g of glass fibers, soaked in KH550 / ethanol solution for 12 hou...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com