Down jacket cleaning agent and preparation technology thereof

A cleaning agent and down jacket technology, applied in the field of down jacket cleaning agent and its preparation, can solve the problems of down softness, elasticity and luster, brittleness, aging, etc., achieve excellent wettability, improve transparency, and reduce stickiness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

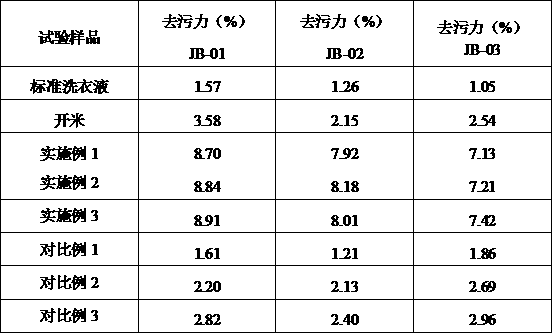

Examples

Embodiment 1

[0021] A down jacket cleaning agent, comprising the following raw materials in mass percentage: 6% of alkyl glucoside, 15% of isomeric tridecyl polyoxyethylene ether, 5% of potassium coconut oleate soap, 10% of isomeric nonylphenol polyoxyethylene ether %, 5% lauryl polyoxyethylene ether, 0.1% chelating titanate coupling agent, 0.1% sodium citrate, 1% triethylene glycol monobutyl ether, and the rest is deionized water.

[0022] The alkyl glycoside is any one of the alkyl glycosides with 12 carbon atoms in the alkyl group and 14 carbon atoms in the alkyl group.

[0023] A preparation method of down jacket cleaning agent, comprising the following steps:

[0024] S1. According to the cleaning agent formula, configure the raw materials of relevant weight;

[0025] S2. In the reaction kettle, add triethylene glycol monobutyl ether, isotridecyl alcohol polyoxyethylene, isomeric nonylphenol polyoxyethylene ether, lauryl alcohol polyoxyethylene ether, mix and stir for 2 minutes, and ...

Embodiment 2

[0029] A down jacket cleaning agent, comprising the following raw materials in mass percentage: 12% of alkyl glycoside, 20% of isomeric tridecyl polyoxyethylene ether, 10% of potassium coconut oleate soap, 15% of isomeric nonylphenol polyoxyethylene ether %, 10% lauryl polyoxyethylene ether, 0.5% chelating titanate coupling agent, 5% sodium citrate, 5% triethylene glycol monobutyl ether, and the rest is deionized water.

[0030] The alkyl glycoside is any one of the alkyl glycosides with 12 carbon atoms in the alkyl group and 14 carbon atoms in the alkyl group.

[0031] A preparation method of down jacket cleaning agent, comprising the following steps:

[0032] S1. According to the cleaning agent formula, configure the raw materials of relevant weight;

[0033] S2. In the reaction kettle, add triethylene glycol monobutyl ether, isotridecyl alcohol polyoxyethylene, isomeric nonylphenol polyoxyethylene ether, lauryl alcohol polyoxyethylene ether, mix and stir for 5 minutes, and...

Embodiment 3

[0037] A down jacket cleaning agent, comprising the following raw materials in mass percentage: 8% of alkyl glucoside, 7% of isomeric tridecyl polyoxyethylene ether, 7% of potassium coconut oleate soap, 8% of isomeric nonylphenol polyoxyethylene ether %, 6% lauryl polyoxyethylene ether, 0.3% chelating titanate coupling agent, 2% sodium citrate, 2% triethylene glycol monobutyl ether, and the rest is deionized water.

[0038] The alkyl glycoside is any one of the alkyl glycosides with 12 carbon atoms in the alkyl group and 14 carbon atoms in the alkyl group.

[0039] A preparation method of down jacket cleaning agent, comprising the following steps:

[0040] S1. According to the cleaning agent formula, configure the raw materials of relevant weight;

[0041] S2. In the reaction kettle, add triethylene glycol monobutyl ether, isotridecyl alcohol polyoxyethylene, isomeric nonylphenol polyoxyethylene ether, lauryl alcohol polyoxyethylene ether, mix and stir for 4 minutes, and fina...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com