A method for electrodepositing flake zinc in alkaline medium

An alkaline medium, electrodeposition technology, applied in electroforming, electrolysis process, etc., can solve the problems of large diameter-to-thickness ratio, difficult to clean zinc powder, inconvenient for further use, etc., to achieve the effect of improving the quality of precipitation and increasing hardness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

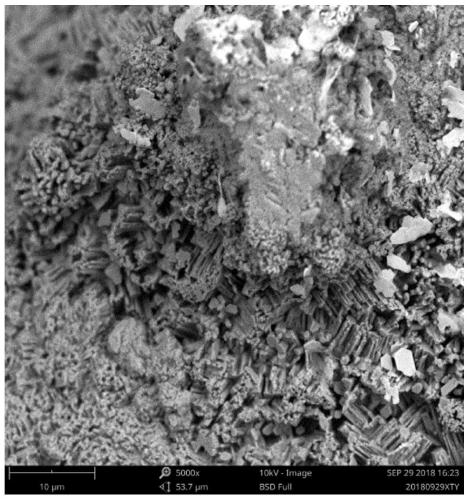

[0027] The current density is 300A / ㎡, the electrolyte temperature is 30°C, the same pole is 10mm, the electrolysis cycle is 2h, the electrolyte contains 25g / LZnO, NaOH 6mol / L, stainless steel is used as anode, titanium sheet is used as cathode, and the stirring speed during electrolysis is 50r / min . Add 0.3g / L gelatin, 0.4g / L ethylenediaminetetraacetic acid disodium salt (EDTA) 0.4g / L, 0.2g / L lead oxide, 0.7g / L dipentaerythritol (DPE) to the solution to obtain flake Metal zinc with a current efficiency of 99.5%. The resulting scanning electron microscope image is figure 1 , which appear as small cubes.

Embodiment 2

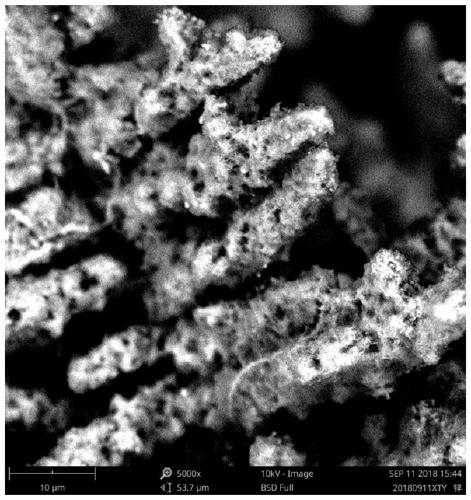

[0031] The current density is 550A / ㎡, the electrolyte temperature is 35°C, the same pole is 10mm, the electrolysis cycle is 2h, the electrolyte contains 30g / L ZnO, NaOH6mol / L, stainless steel is used as anode, titanium sheet is used as cathode, and the stirring speed during electrolysis is 60r / min . Add 0.2g / L of gelatin, 0.5g / L of disodium ethylenediaminetetraacetic acid (EDTA), 0.1g / L of lead carbonate, and 0.4g / L of dipentaerythritol (DPE) into the solution to obtain flake Metal zinc with a current efficiency of 99.2%. The resulting scanning electron microscope image is image 3 , in small lumps.

Embodiment 3

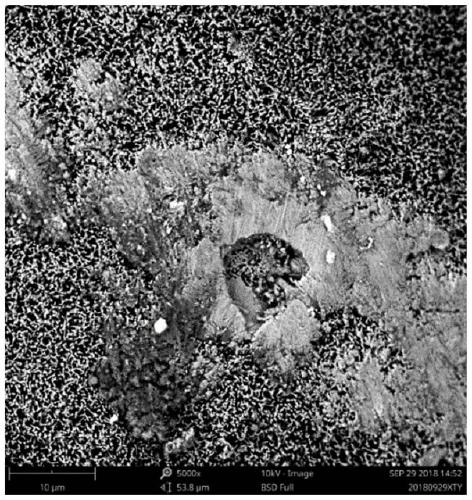

[0035] The current density is 300A / ㎡, the electrolyte temperature is 40°C, the same pole is 10mm, the electrolysis cycle is 2h, the electrolyte contains 20g / L ZnO, NaOH6mol / L, stainless steel is used as anode, titanium sheet is used as cathode, and the stirring speed during electrolysis is 70r / min . Add 0.3g / L gelatin, 0.6g / L ethylenediaminetetraacetic acid disodium salt (EDTA), 0.3g / L lead sulfate, and 0.5g / L dipentaerythritol (DPE) to the solution to obtain flake Metal zinc with a current efficiency of 99.6%. The obtained product picture is as follows Figure 5 , the resulting product is smooth and flat, in the form of flakes.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com