Injection system used gravity to realize automatic adjustment of oil field injection well and using method

An automatic adjustment and injection system technology, applied in earthwork drilling, wellbore/well components, production fluid, etc., can solve problems such as large value difference, high initial investment and maintenance cost, and inaccurate data

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

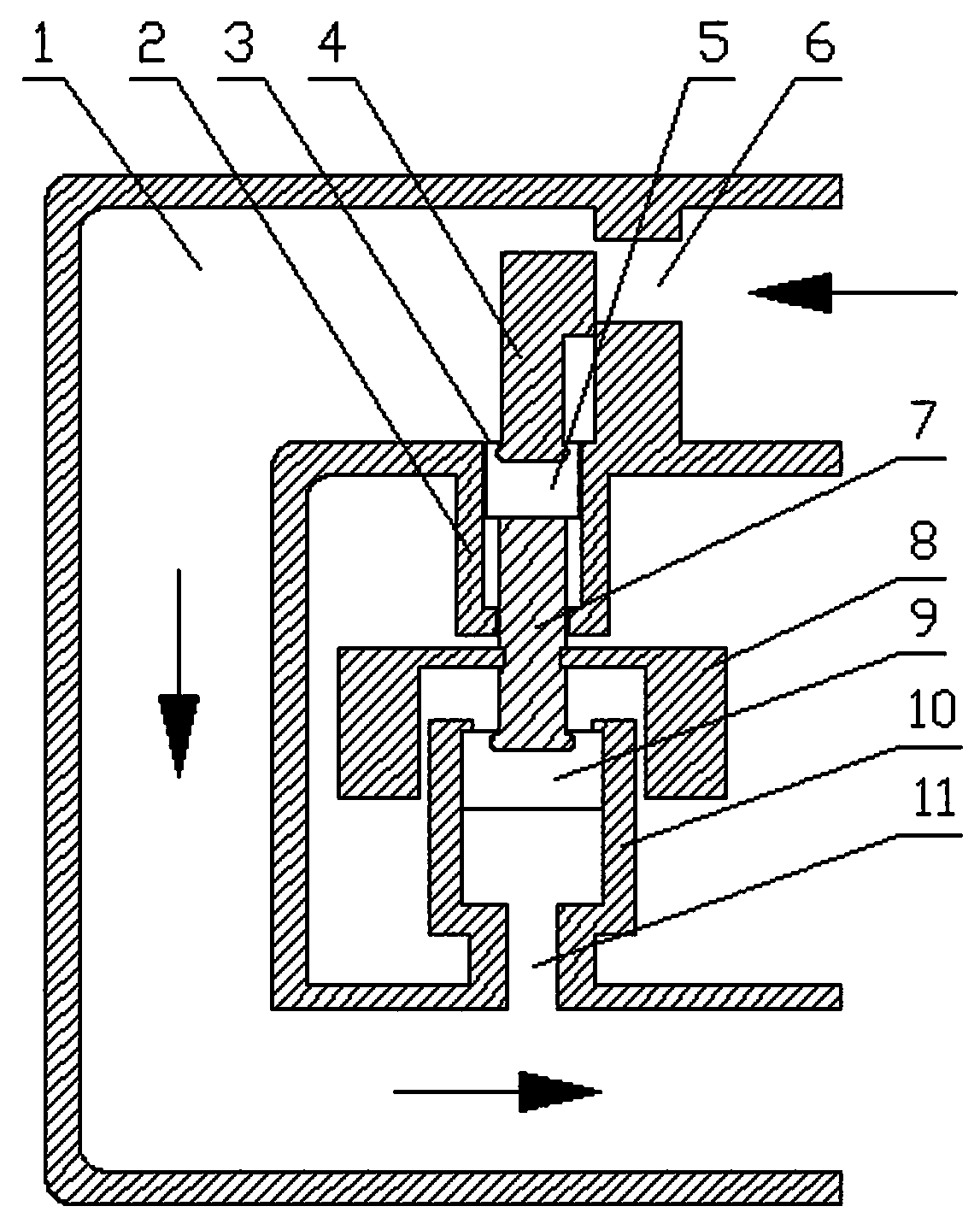

[0027] refer to figure 1 , the pipeline pressure (injection pressure) behind the oil pressure valve (i.e. flow control valve) is induced in two hydraulic cylinders at the same time, and the pressure generated in the two hydraulic cylinders acts on two different cross-sectional areas (S 1 , S 2 , S 1 2 ) size of the piston, the forces generated are PS 1 、PS 2 , since the pressure in the cylinder is the same, it is obvious that PS 1 2 , according to the above features, the two pistons and the control part 4 of the oil pressure valve have linkage to form a whole, then the whole will be moved due to uneven force, because the whole and the control part 4 of the oil pressure valve have linkage It will drive the opening and closing of the valve port 6 to change, and then the flow rate will change, and the change in the flow rate will in turn affect the injection pressure; when the gravity effect of the gravity loading part 8 is not loaded, due to the PS 1 always less than PS 2 ...

Embodiment 2

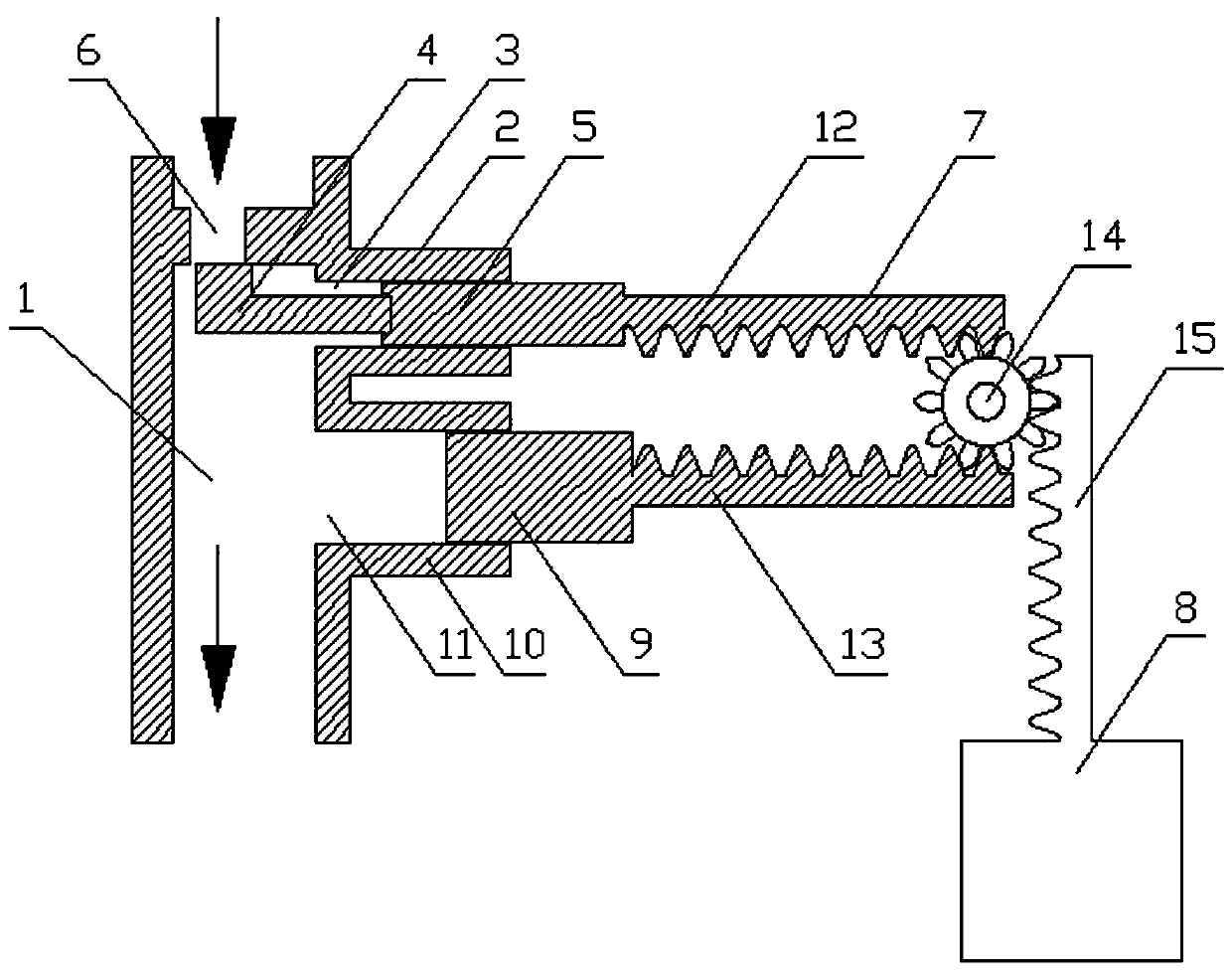

[0030] refer to figure 2 , the cross-sectional areas of the first piston 5 and the second piston 10 are respectively S 1 and S 2 , and S 1 less than S 2 , the meshing radius between the first rack 12 and the second rack 13 and the gear 14 is R 1 , the meshing radius between the third rack 15 and the gear 14 is R 2 , the positions of the third rack 15, the first rack 12 and the second rack 13 on the gear 14 are misaligned, and the forces generated on the first piston 5 and the second piston 10 are respectively PS 1 and PS 2 , and PS 1 less than PS 2 , the counterweight of gravity loading part 8 is G, PS 1 、PS 2 and G are transmitted to the gear 14 through the rack to generate torque on it, when PS 2 R 1 =PS 1 R 1 +GR 2 (Note: When G does not need to be enlarged, R 1 =R 2 , when it is necessary to amplify R 1 2 , simplified to R in the structure diagram 1 =R 2 When the situation), that is, P=GR 2 / (S 2 -S 1 ) R 1 , the overall force is balanced, then P is...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com