Metallurgy air separation oxygen supply pipe network system and operation method thereof

An operation method and technology of oxygen supply pipes, which are applied in the pipeline system, gas/liquid distribution and storage, mechanical equipment, etc., can solve the problem of high energy consumption and release loss of oxygen compression, the buffer potential of spherical tanks has not been fully utilized, Buffer capacity, oxygen release and other issues, achieve the effect of reducing the investment of spherical tanks, increasing the release range and buffer capacity, and realizing the pressure reduction of the pipe network

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

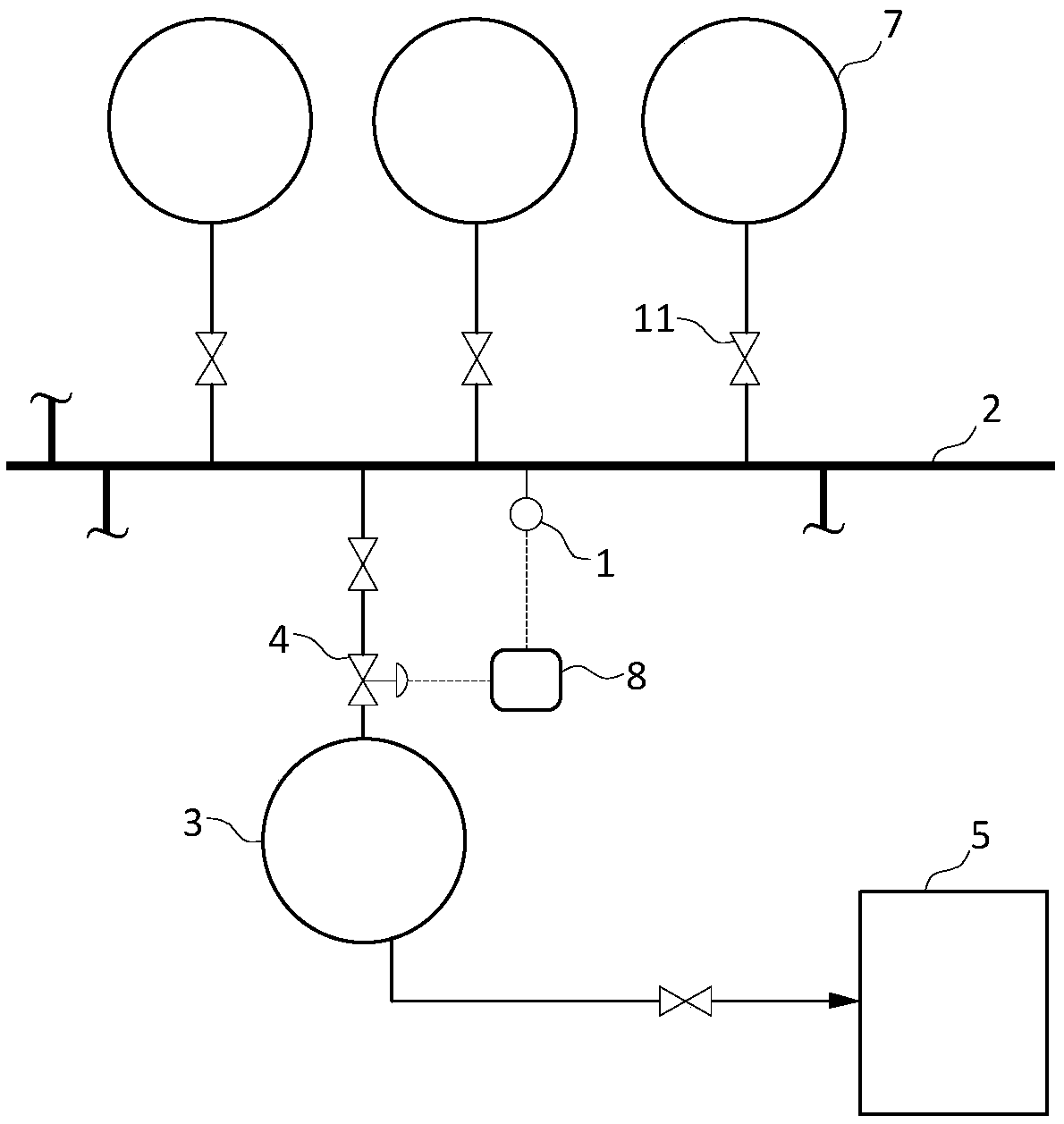

[0033] Such as figure 2 Shown is a partial flow chart of the oxygen supply pipeline network system in Embodiment 1. The first step of implementation is: select one or more spherical tanks in the oxygen supply network system as the first spherical tank 3, and then build a spherical tank control system according to the requirements of the operation method provided by the present invention. Such as figure 2 As shown, the specific construction method is: add a special valve-4 between the first spherical tank 3 and the high-pressure pipe network 2, and at the same time add an air supply pipeline between the first spherical tank 3 and the low-pressure user 5, and install a valve in the high-pressure pipe network. A pressure sensor 1 is set on the network 2, a signal connection line is set between the sensor and the controller 8, and a signal connection line is set between the controller 8 and the valve one 4, thereby forming a spherical tank control system. When there are multip...

Embodiment 2

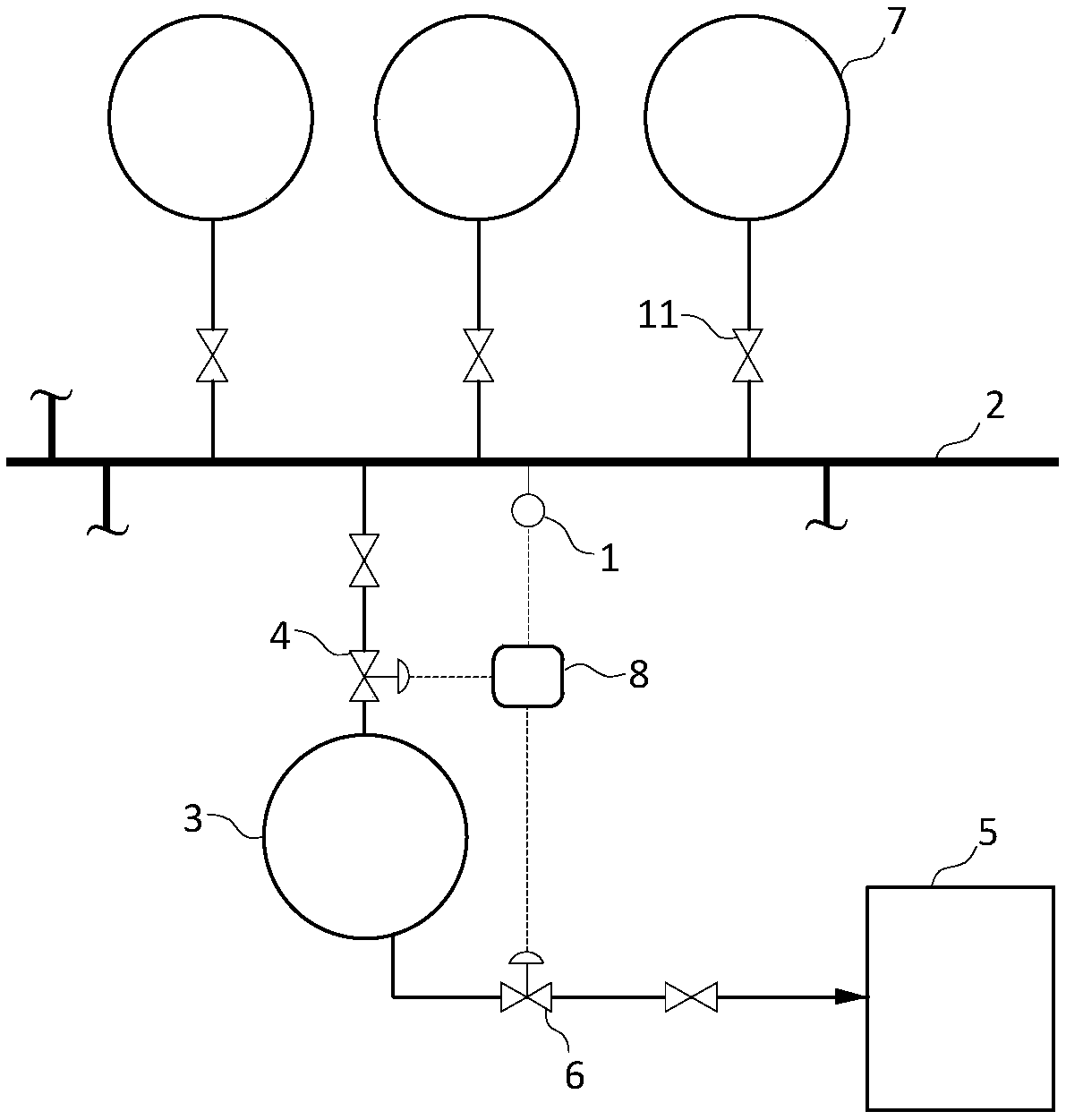

[0036] Such as image 3 Shown is a partial flow chart of the oxygen supply pipe network system in Embodiment 2 of the present invention. The first step of implementation is to select one or more spherical tanks in the oxygen supply network system as the first spherical tank, and then construct a spherical tank control system according to the requirements of the operation method provided by the present invention. Such as image 3 As shown, the specific construction method is as follows: a special valve 4 is added between the first spherical tank 3 and the high-pressure pipe network 2, and an air supply pipeline is added between the first spherical tank 3 and the low-pressure user 5, and the air supply Valve two 6 is set on the pipeline; pressure sensor 1 is set on the high-pressure pipe network 2, and a signal connection line is set between the sensor and the controller 8, between the controller 8 and the valve one 4, and between the controller 8 and the valve two 6 Signal co...

example 1

[0041] The total output of an air separation plant in a steel company in my country is 150,000Nm 3 / h, there are 5 sets of 1000m in the oxygen supply pipe network system 3 Oxygen spherical tanks, all of which are connected to the high-pressure pipe network. According to the production data of 30 days of normal production, the maximum pressure of the high-pressure pipe network is 2.54MPa, the minimum pressure is 1.82MPa, and the average pressure is 2.32MPa. The oxygen pressure of the blast furnace is 0.5MPa, and the average oxygen release rate is 2.43%. According to the calculation, the release range of the spherical tank is 0.72MPa, and the total buffer capacity of all spherical tanks is 36000m 3 , The buffer capacity is about the total output of the air separation unit for 15 minutes.

[0042] According to air separation output, pressure fluctuation, spherical tank volume and blast furnace oxygen consumption, etc., 3 tanks were transformed into the first spherical tank, and...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com