Pipeline corrosion measuring instrument signal calibration device

A calibration device and technology of corrosion degree, applied in the field of signal calibration, can solve the problems of signal distortion, frequency hopping, uncontrollable working environment of pipeline corrosion detector, etc., and achieve the effect of improving switching speed and load capacity.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

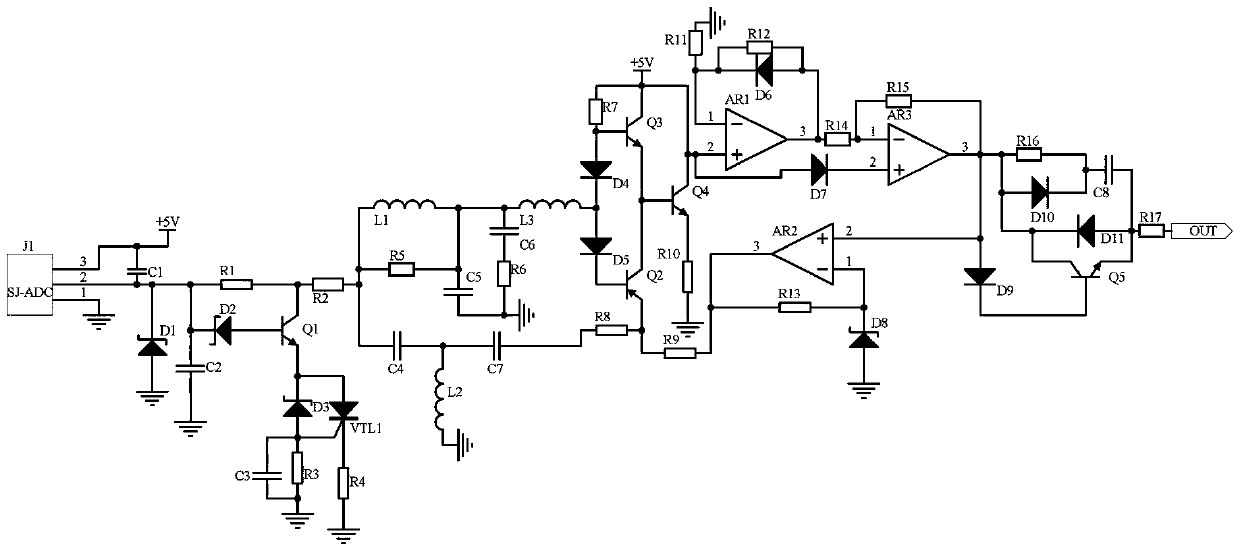

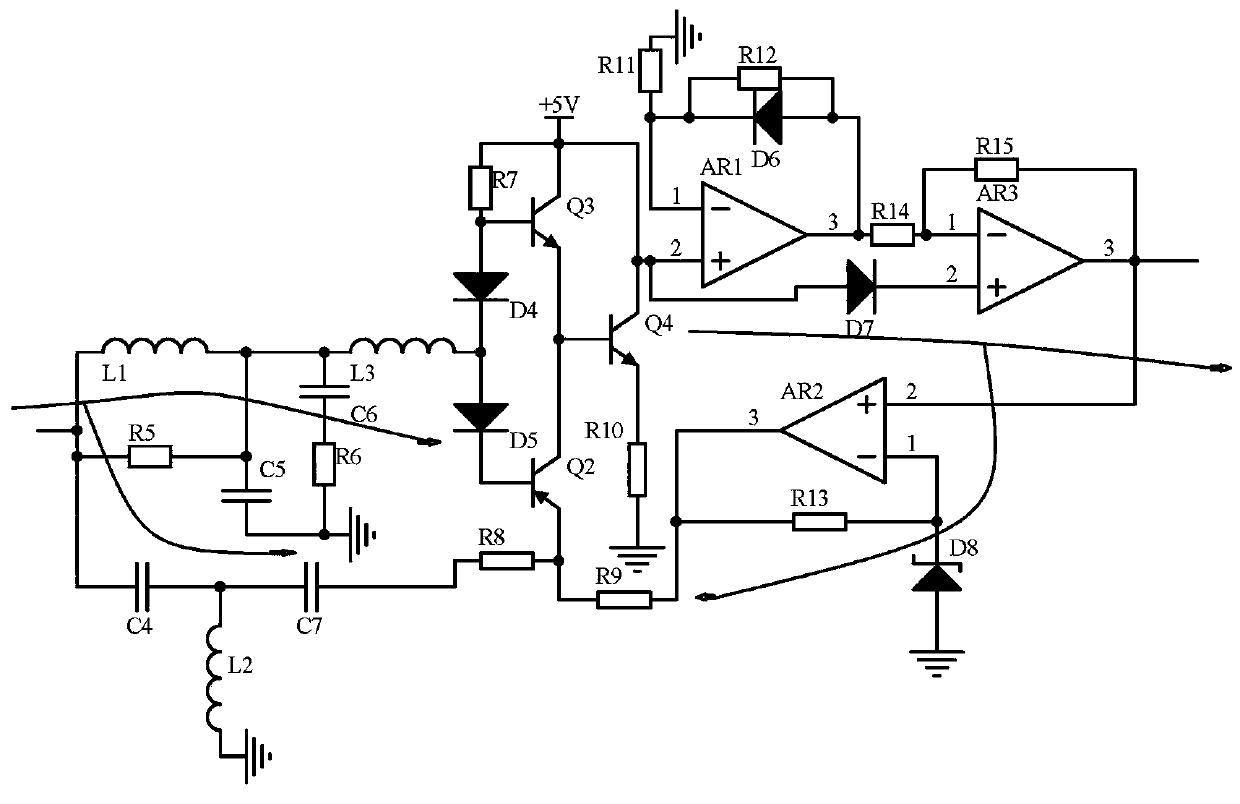

[0014] Embodiment 1, a signal calibration device for a pipeline corrosion degree measuring instrument, including a frequency acquisition circuit, a frequency division feedback circuit and a buffer output circuit, the frequency acquisition circuit collects the frequency of an analog signal when the pipeline corrosion degree measuring instrument is working, and the analog signal is the pipeline The corrosion degree measuring instrument controls the signal received by the terminal, and uses the triode Q1, diode D3 and triac VTL1 to filter out abnormal signals. The frequency division feedback circuit uses the inductor L1, capacitor C4, and capacitor C5 to form a frequency division circuit to collect frequency The output signal of the circuit is frequency-divided, and then the push-pull circuit composed of transistor Q3, transistor Q2, transistor Q4, diode D4, and diode D5 is used to process the signal, which not only improves the load capacity of the circuit, but also improves the s...

Embodiment 2

[0016] Embodiment 2, on the basis of Embodiment 1, the buffer output circuit uses the RCD buffer circuit to buffer the signal, which can make the signal smoothly compensate the analog signal when the pipeline corrosion degree measuring instrument is working, so that the signal will not be abnormal, and the resistance One end of R16 is connected to the output end of operational amplifier AR3, the anode of diode D10 and the cathode of diode D11, and the collector of transistor Q5. The other end of resistor R16 is connected to the cathode of diode D10 and one end of capacitor C8. The other end of capacitor C8 is connected to The anode of the diode D11, one end of the resistor R17 and the emitter of the transistor Q5, the base of the transistor Q5 are connected to the cathode of the diode D9, and the other end of the resistor R17 is connected to the signal output port.

[0017]Implementation three, on the basis of embodiment one, the frequency acquisition circuit selects the freque...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com