Photovoltaic cable and its preparation process

A photovoltaic cable and preparation process technology, used in cable/conductor manufacturing, insulating cables, insulating conductors/cables, etc., can solve the problem of affecting the use of photovoltaic systems, and it will exist between the insulating layer and the sheath layer if it is not completely dried , When used in places with high temperature and long production cycle, it can achieve good corrosion resistance, reduce adverse effects and long service life.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

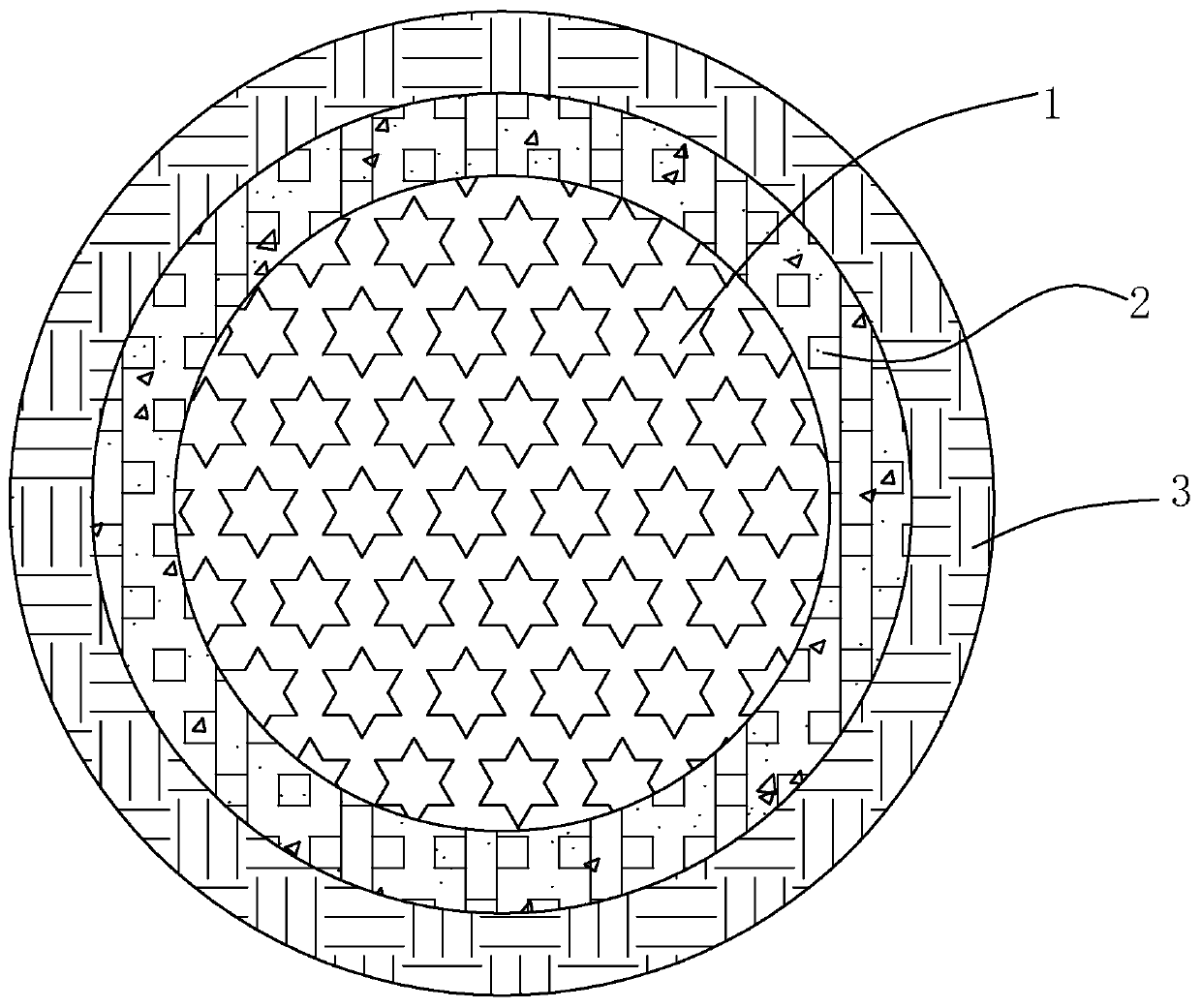

[0052] refer to figure 1 , is a photovoltaic cable disclosed in the present invention, including tinned copper soft wire 1, and an insulating layer 2 and a sheath layer 3 that are sequentially coated on the peripheral wall of the galvanized copper soft wire from the inside and outside and integrally formed. The insulating layer 2 is composed of low-smoke, halogen-free, flame-retardant polyolefin insulating material, and the sheath layer 3 is composed of low-smoke, halogen-free, flame-retardant polyolefin sheathing material.

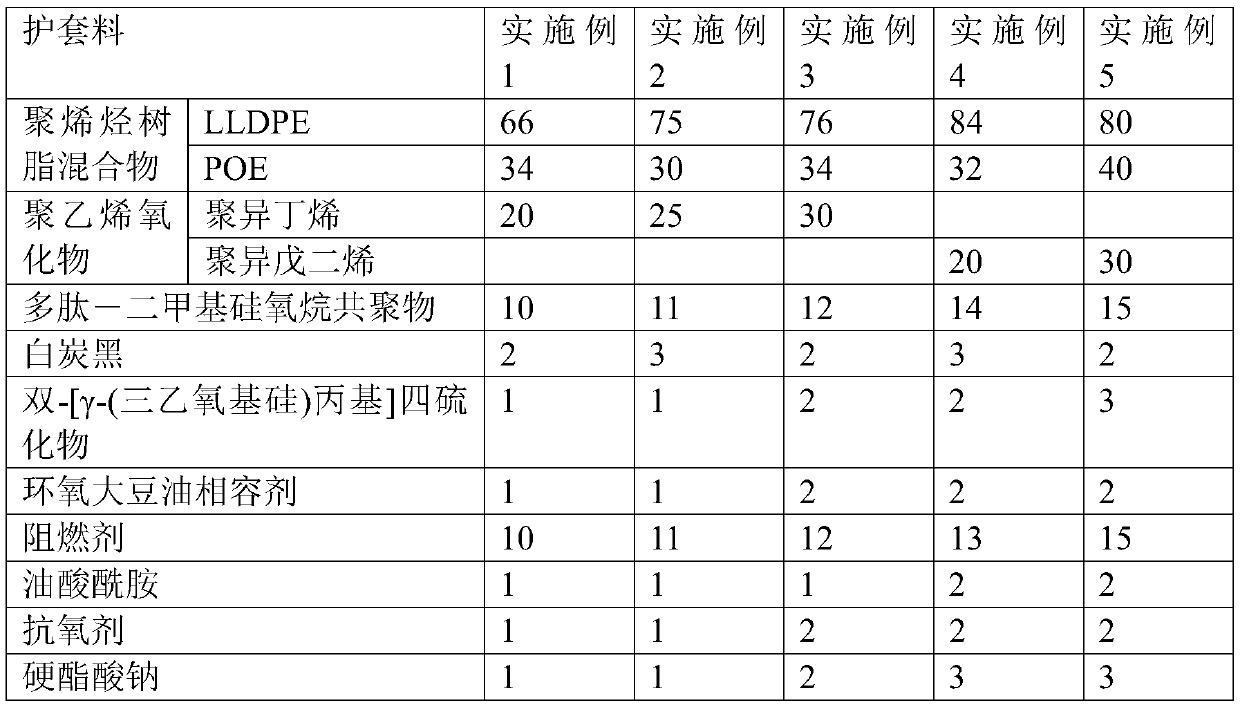

[0053] The specific low-smoke halogen-free flame-retardant polyolefin sheathing material includes the following components by weight: LLDPE 66kg, POE 34kg, polyisobutylene 20kg, polypeptide-dimethylsiloxane copolymer 10kg, white carbon black 2kg, bis-[γ -(triethoxysilyl)propyl]tetrasulfide 1kg, epoxy soybean oil compatibilizer 1kg, flame retardant 10kg, oleic acid amide 1kg, 2,6-di-tert-butyl-4-aminophenol 0.5kg , Tris(2,4-di-tert-butylphenyl)phosphite 0...

Embodiment 6

[0064] The preparation process of the photovoltaic cable comprises the following preparation steps:

[0065] Step 1: Prepare tinned copper soft wire 1, low-smoke, halogen-free, flame-retardant polyolefin insulation material and low-smoke, halogen-free, flame-retardant polyolefin sheath material;

[0066] Step 2: Tension the tinned copper soft wire 1 through the tension frame and convey it forward at a constant speed, and the conveying speed is 180m / min;

[0067] Step 3: Use a vacuum twin-screw extruder for extrusion operation. The vacuum twin-screw extruder includes two extrusion screws and a vacuum co-extrusion die. Add low-smoke, halogen-free and flame-retardant The polyolefin insulation material is melt-extruded, and the low-smoke, halogen-free and flame-retardant polyolefin sheath material is added to the hopper of another extrusion screw, and the insulating layer 2 is extruded first, and then when the insulating layer 2 is in a molten state, the second The extrusion scre...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com