Method for detaching ring teeth of Peruvian squid sucker

A Peruvian squid and sucker technology, which is applied in the field of seafood processing, can solve the problems of high degree of bite between the sucker and ring teeth, difficulty in detachment, and lack of effective utilization methods, so as to achieve low cost of degearing, increase the degearing rate, and ensure quality effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

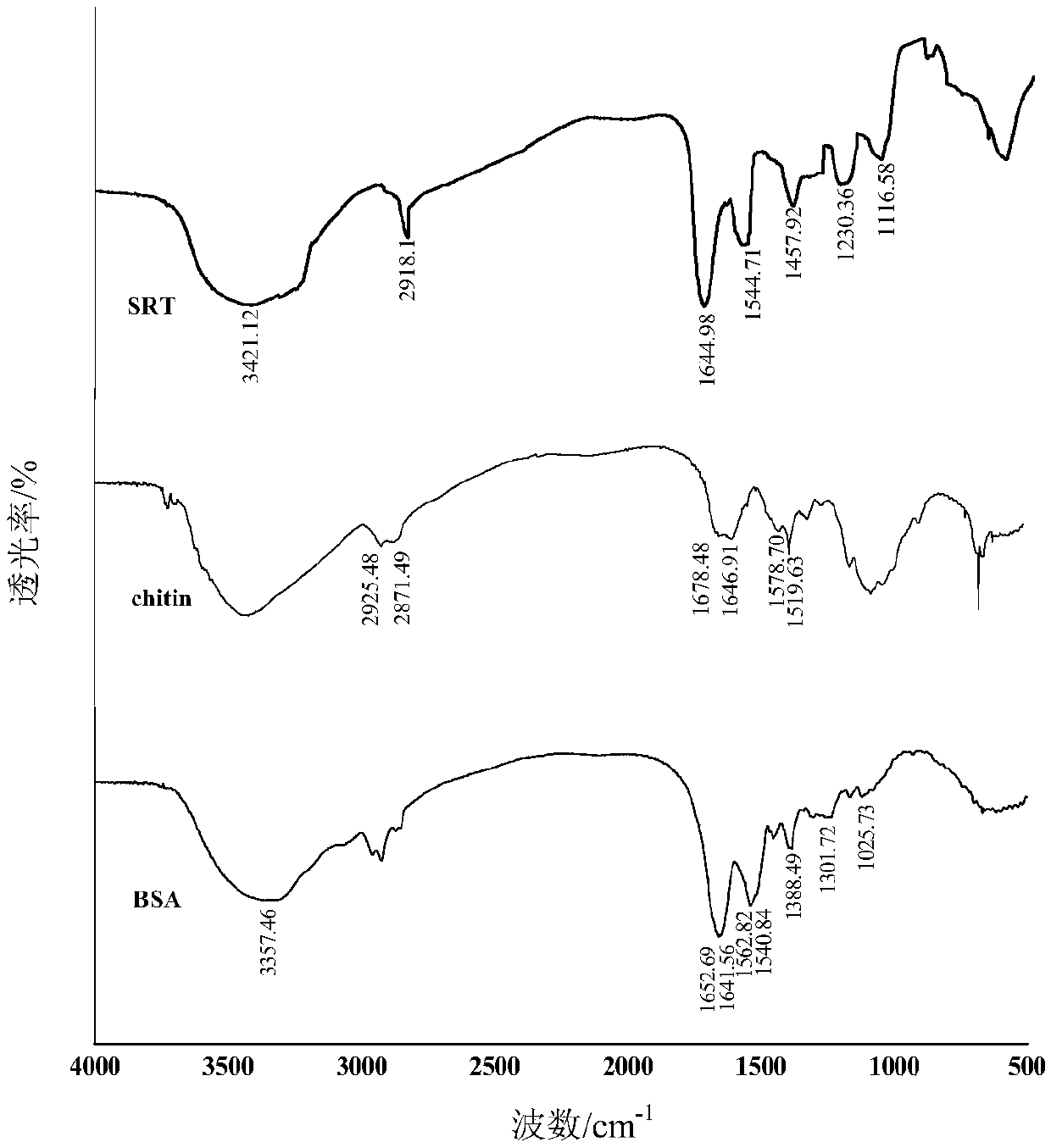

[0025] Example 1: Research on sucker ring teeth of Peruvian squid

[0026] Raw materials: Frozen Peruvian squid silk, purchased from Zhoushan Haili Oceanic Fishery Co., Ltd.

[0027] Reagents: standard bovine serum albumin, Sigma Company of the United States; chitin, Shanghai Sangong Bioengineering Co., Ltd.; other hydrochloric acid and sodium hydroxide reagents were of analytical grade, Sinopharm Chemical Reagent Co., Ltd.

[0028] Instruments and equipment: Nicolet 6700 infrared spectrometer, Thermo Nicolet Company of the United States; HH-4 electric heating constant temperature water bath, Changzhou Guohua Electric Co., Ltd.; LGJ-10 freeze dryer, Beijing Songyuan Huaxing Technology Development Co., Ltd.; GZX-9240MBE electric heating Blast drying oven, Shanghai Boxun Industrial Co., Ltd.; Phenom desktop scanning microscope, Funa Scientific Instruments Shanghai Co., Ltd.; DFT-250 high-speed universal pulverizer, Shanghai Chuding Analytical Instrument Co., Ltd.; 200F 3 differe...

Embodiment 2

[0051] A method for detaching the sucker ring teeth of Peruvian squid, comprising the following steps:

[0052] (1) Pretreatment: thaw the frozen squid, wash and drain, and set aside.

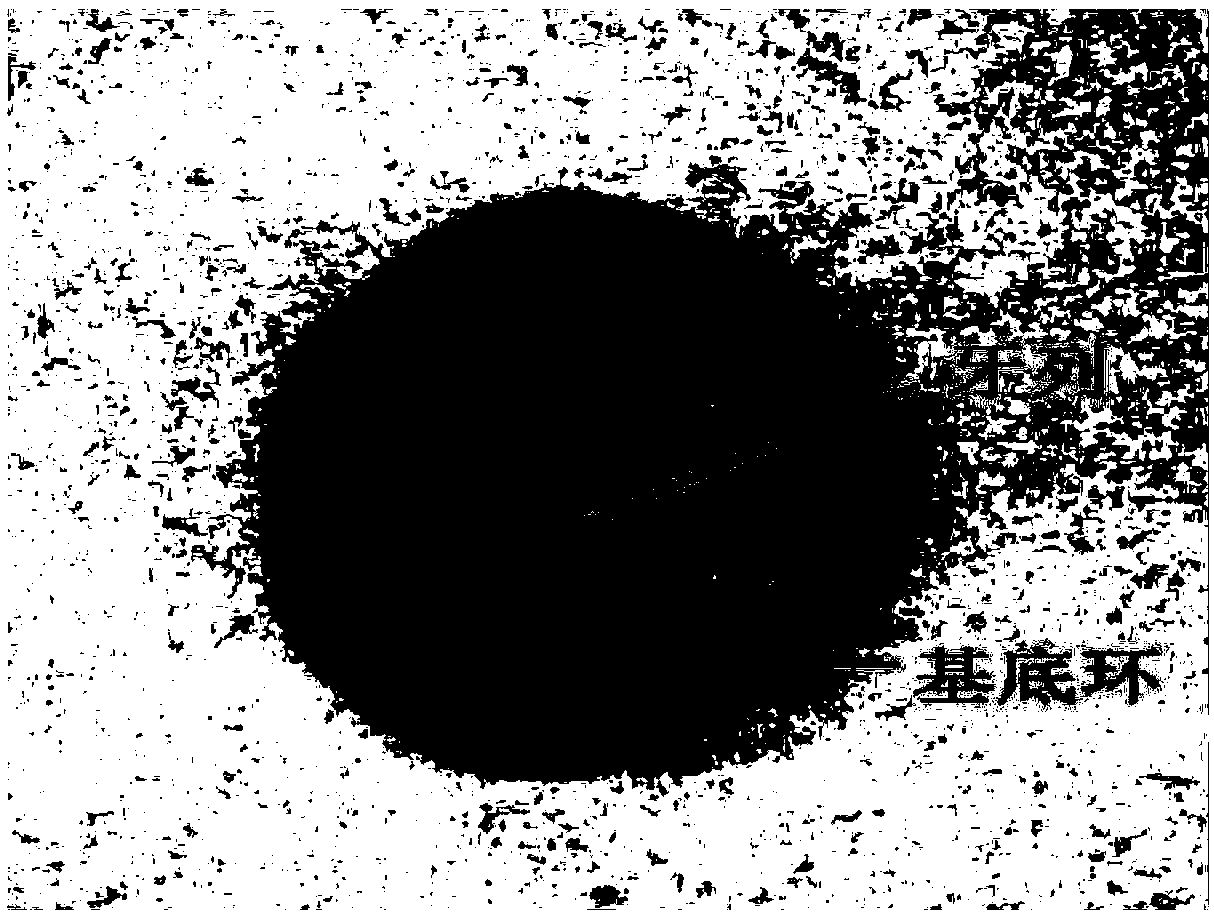

[0053] (2) Pre-separation: place the pretreated squid whiskers on a heating plate, then place an extrusion plate on the squid whiskers, heat at 60°C for 4 seconds, and squeeze the squid whiskers with the squeeze plate during the heating process. It can be seen from Example 1 that the main component of ring teeth is protein, and protein has the problem of heat denaturation, so in this example, the heating temperature is set at 60°C and the heating time is set at 4s. After the ring tooth is heated, it softens and has a certain adhesion with the extrusion plate, so that the extrusion plate can have a certain stretching effect between the ring tooth and the suction cup while extruding the ring tooth, so as to realize the suction cup and the sucker. Separation of ring teeth.

[0054] (3) Rapid coo...

Embodiment 3

[0057] A method for detaching the sucker ring teeth of Peruvian squid, comprising the following steps:

[0058] (1) Pretreatment: thaw the frozen squid, wash and drain, and set aside.

[0059] (2) Pre-separation: place the pretreated squid whiskers on a heating plate, then place an extrusion plate on the squid whiskers, heat at 80°C for 3 seconds, and squeeze the squid whiskers with the squeeze plate during the heating process. It can be seen from Example 1 that the main component of ring teeth is protein, and protein has the problem of heat denaturation, so in this example, the heating temperature is set at 80°C and the heating time is set at 2s. After the ring tooth is heated, it softens and has a certain adhesion with the extrusion plate, so that the extrusion plate can have a certain stretching effect between the ring tooth and the suction cup while extruding the ring tooth, so as to realize the suction cup and the sucker. Separation of ring teeth.

[0060] (3) Rapid coo...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Concentration | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com