Titanium alloy sheet electric auxiliary segmentation progressive forming device and method

A kind of incremental forming, electric-assisted technology, applied in metal processing, forming tools, metal processing equipment and other directions, can solve the problems of low material utilization, serious oxidation of parts, long forming cycle, etc., to achieve fast heating speed, high processing efficiency, The effect of improving the formability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

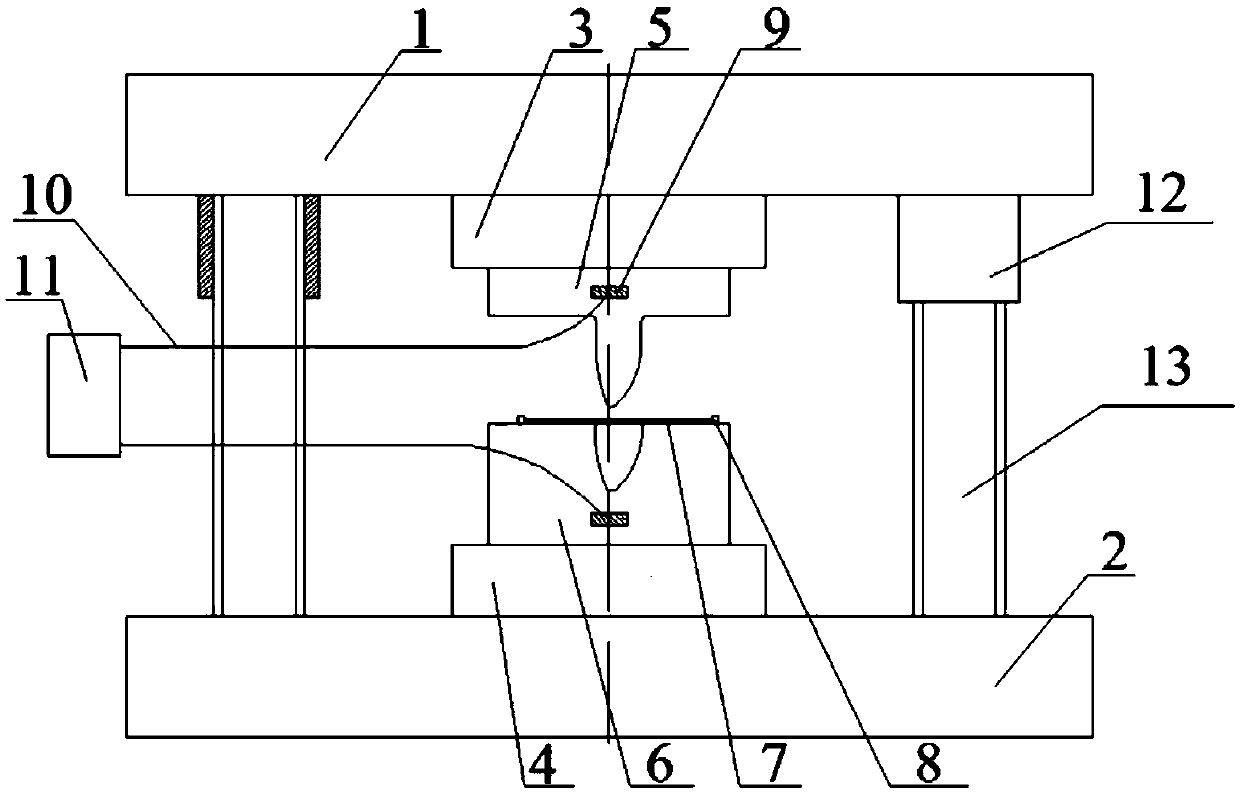

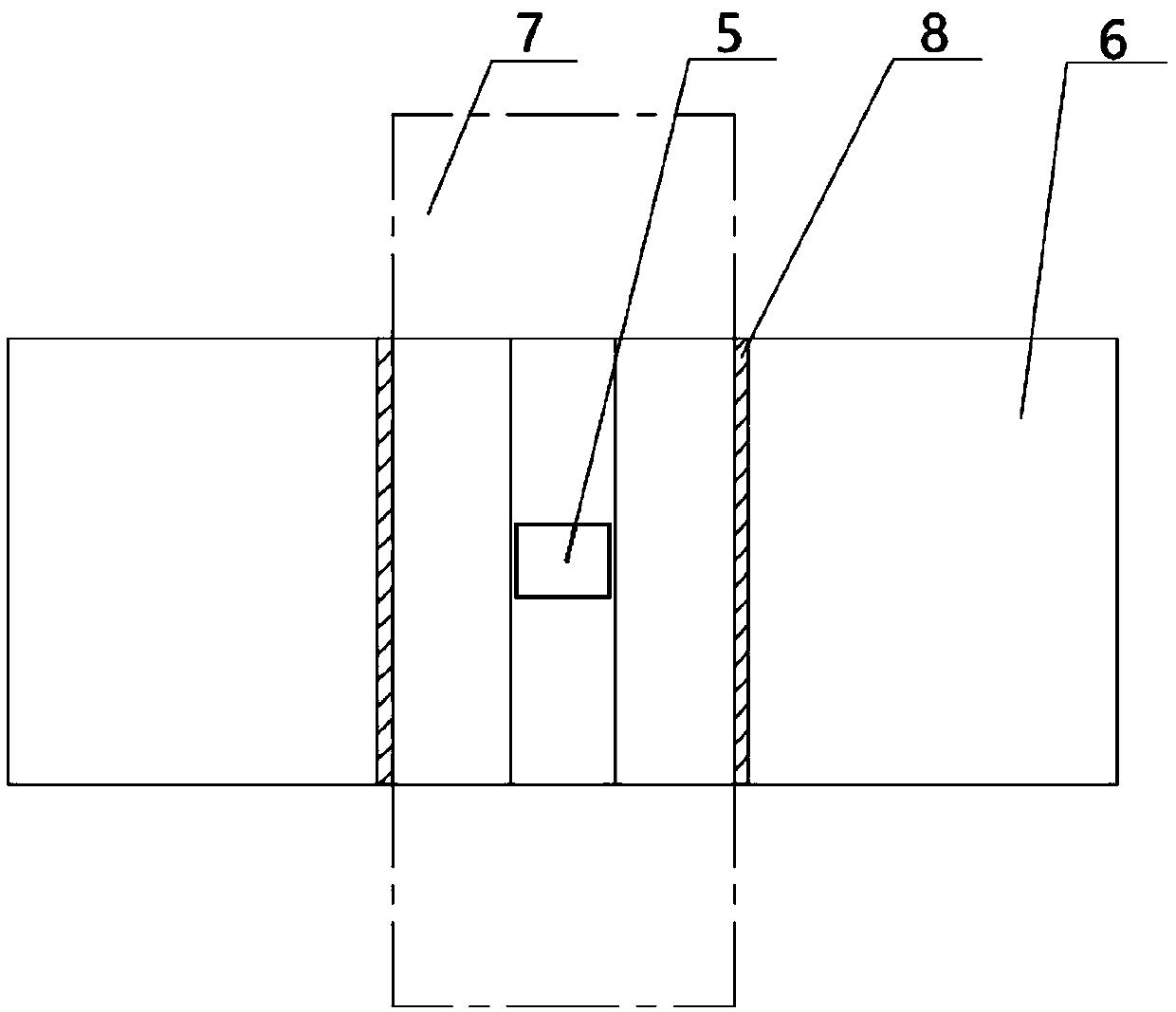

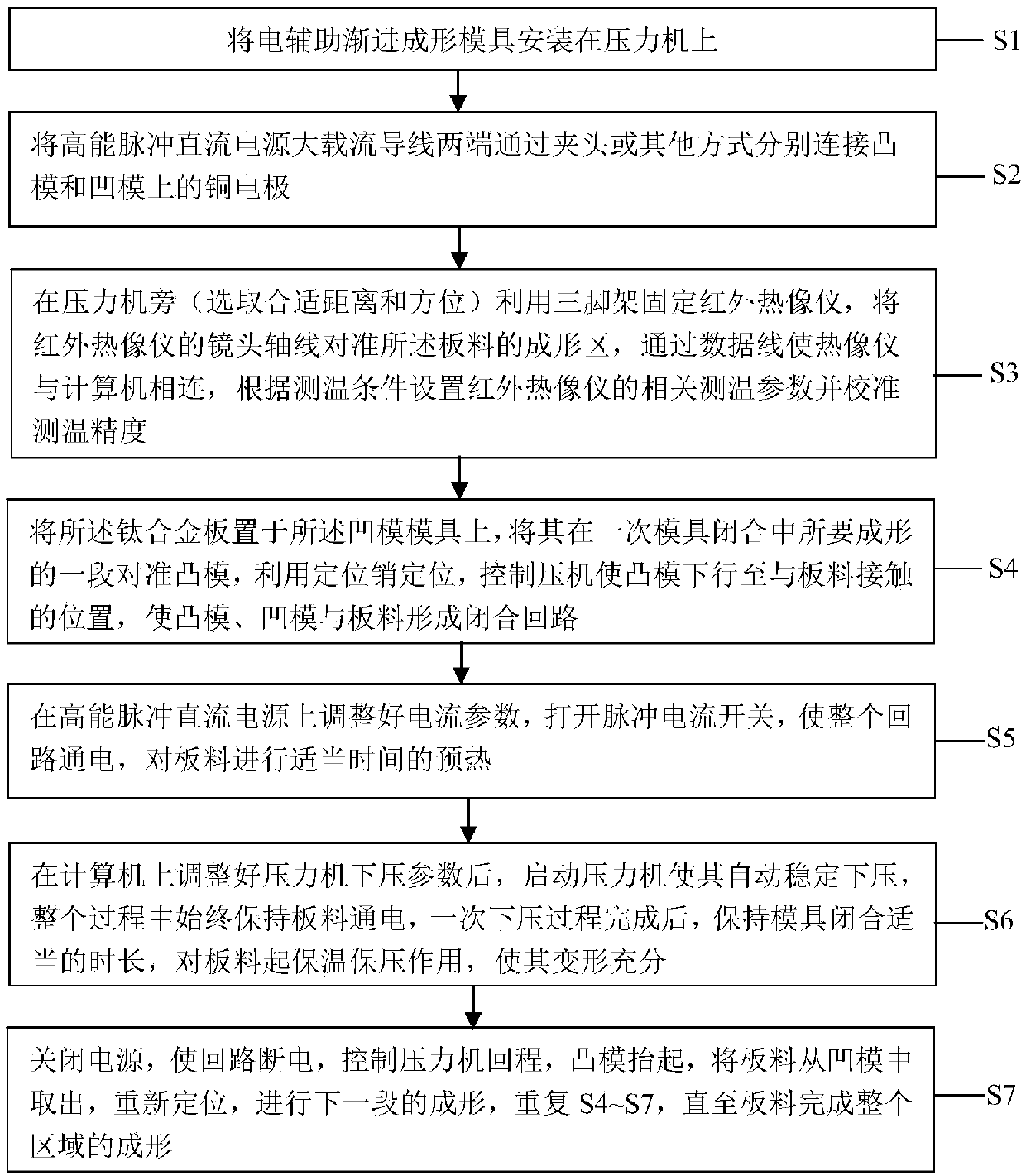

[0032] Such as figure 1 , 2 As shown, it is an electric-assisted segmental progressive forming device for titanium alloy thin plates. In this embodiment, the processed mold and corresponding titanium alloy thin plates are used to conduct experiments to verify the electrical-assisted segmental progressive forming of large titanium alloy sheets in actual production. The forming process, the forming device includes: upper mold base 1, lower mold base 2, upper insulating backing plate 3, lower insulating backing plate 4, punch 5, die 6, titanium alloy sheet 7, sheet positioning pin 8, copper An electrode 9, a large current-carrying wire 10, a high-energy DC pulse power supply 11, a guide sleeve 12 and a guide post 13.

[0033] Wherein, the upper mold module and the lower mold module are connected through the guide pillar 13, and the titanium alloy sheet 7 is formed when the mold is closed, and the temperature measuring device measures the temperature of the sheet and the contact ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com