Electrochemical ceramic membrane oxygen producing machine and oxygen producing equipment thereof

An oxygen-generating equipment and ceramic membrane technology, applied in the field of electrochemical ceramic membrane oxygen-generating machines and oxygen-generating equipment, can solve the problems of short service life, small oxygen-generating capacity, and many moving parts, etc., and save the use cost and structure. Simple and reliable, technically optimal results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] The technical solutions in the embodiments of the present invention are clearly and completely described below in conjunction with the accompanying drawings in the embodiments of the present invention. Obviously, the described embodiments are part of the embodiments of the present invention, but not all of them. Based on the embodiments of the present invention, all other embodiments obtained by those skilled in the art without making creative efforts belong to the protection scope of the present invention.

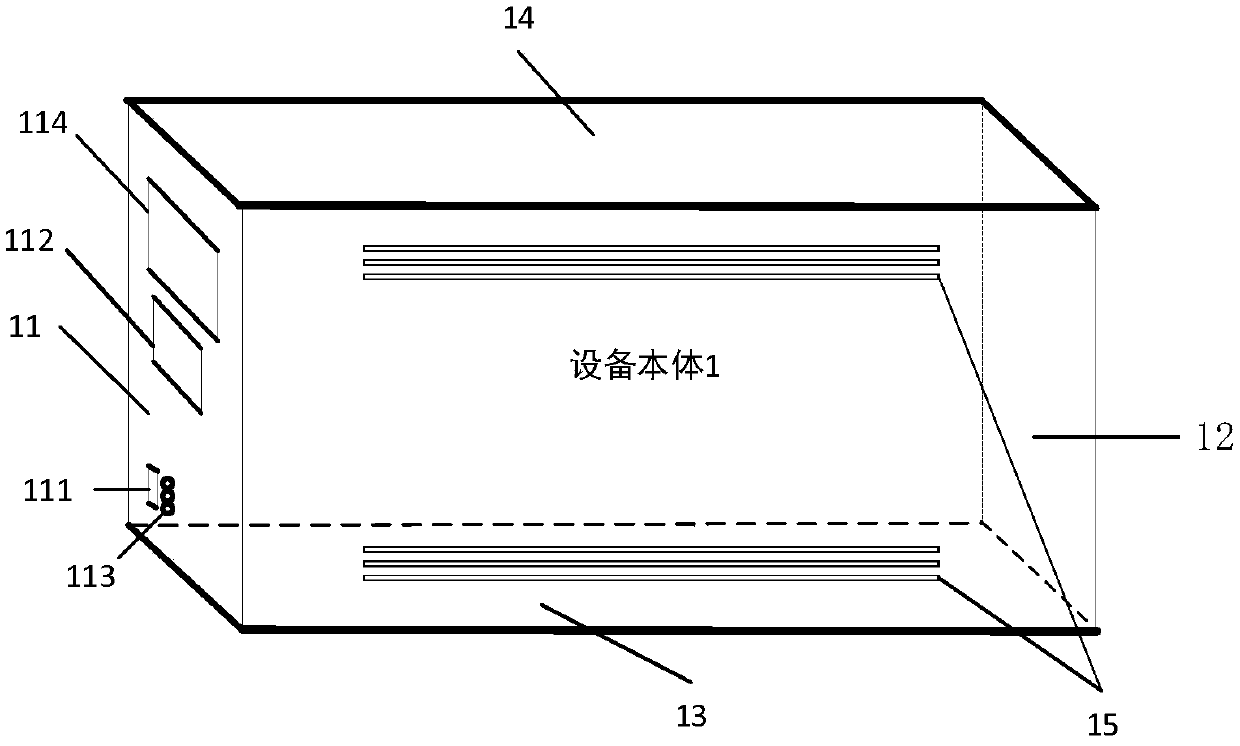

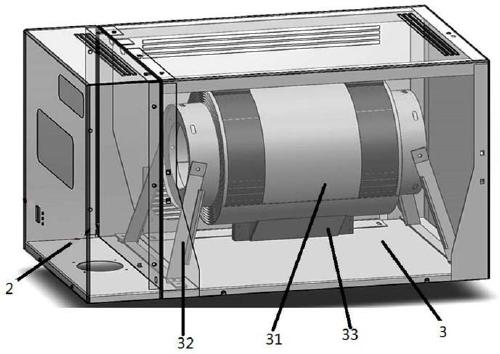

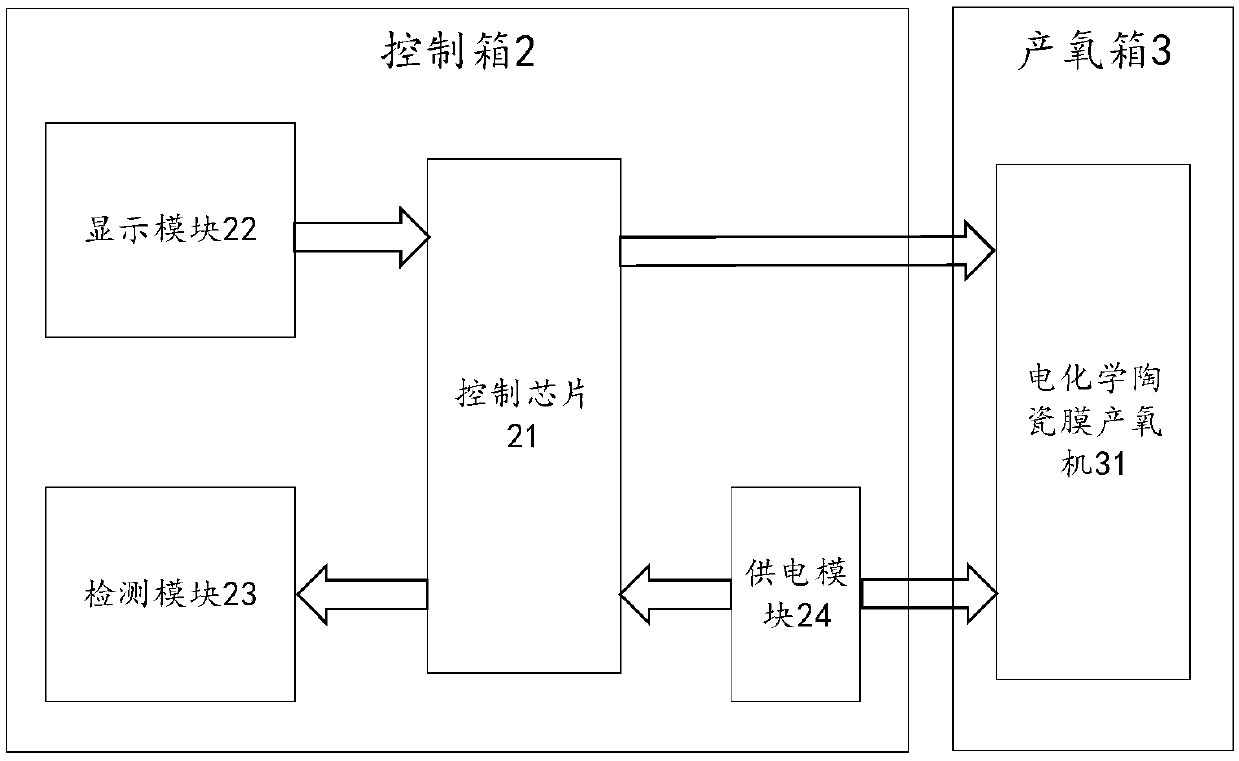

[0029] Such as figure 1 As shown, the embodiment of the present application provides an oxygen generator, which includes a device body 1, the device body 1 consists of a front panel 11, a rear panel 12, two parallel side panels (not shown), a bottom plate 13 and a cover plate 14 parallel to the bottom plate 13 surround a cuboid. On the front panel 11, a running switch 111, a control panel 112, an indicator light 113 and a display screen 114 are set, wherein the ru...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com