Multifunctional paint suitable for battery box and preparation method and application of multifunctional paint

A multi-functional, battery box technology, applied in conductive coatings, anti-corrosion coatings, fire-resistant coatings, etc., can solve the problems of inability to improve the heat dissipation performance of battery boxes, poor anti-corrosion and fire prevention effects, and unknown alkali resistance, etc., and achieve excellent adhesion , heat dissipation effect is obvious, the effect of excellent comprehensive performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

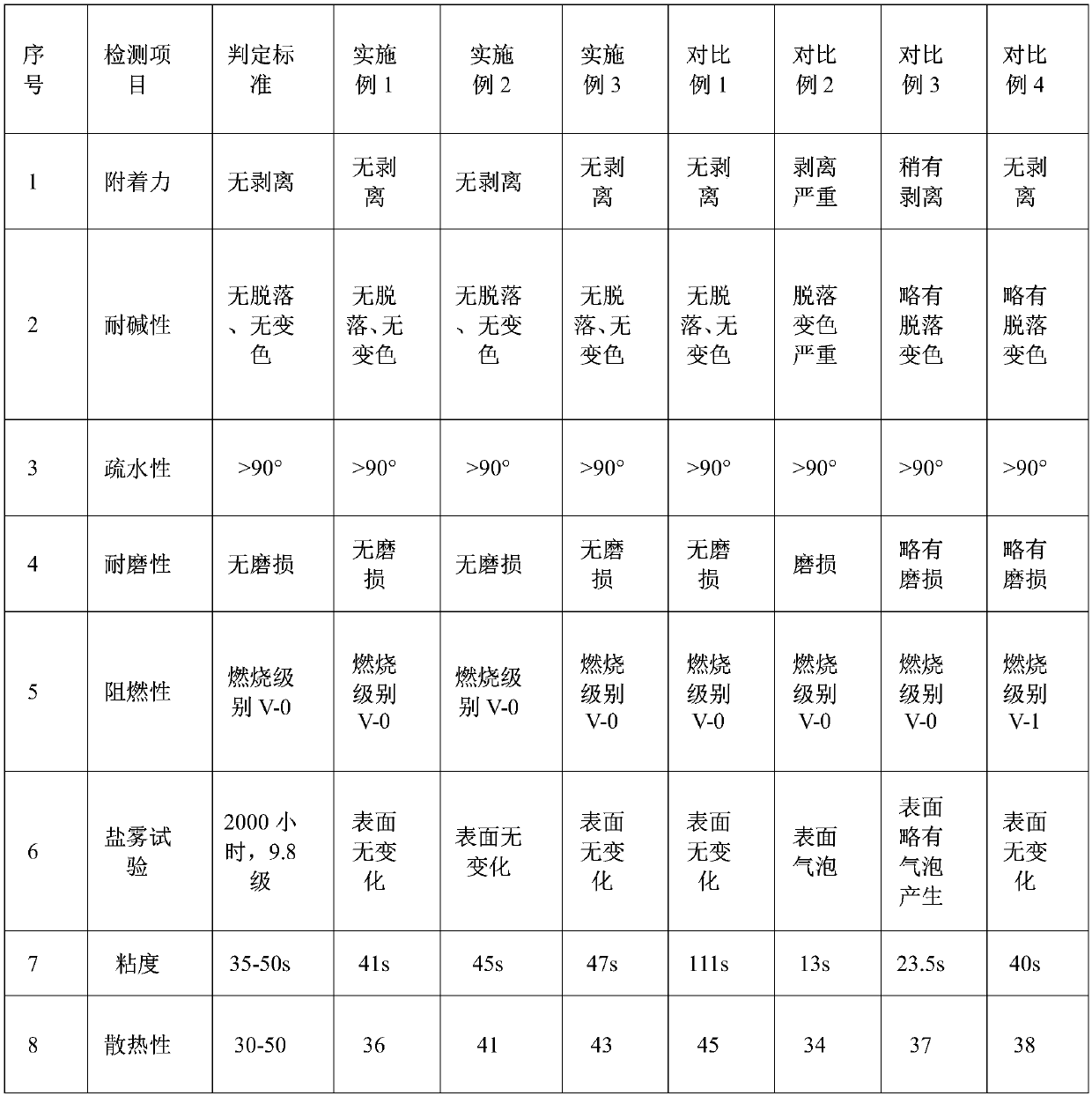

Examples

Embodiment 1

[0037] The present embodiment provides a kind of multifunctional coating that is applicable to battery box, and its raw material comprises: graphene aqueous solution 45% (the mass content of graphene is 10%), water-based resin 30% (wherein polyurethane RU -71-035 and acrylic resin AC-106 mixed at a mass ratio of 6:4), polyvinylpyrrolidone PVP: 0.9%, polydimethylsiloxane Ls-3110: 0.5%, dimethylethanolamine DEMA: 0.6%, Polyacrylate thickener DN-2222: 0.8%, modified polycarbodiimide crosslinking agent XR-5580: 1.0%, polydimethylsiloxane wear agent DC-51: 5%, silicone resistance Combustion agent DC-8008: 15%, oily defoamer T-501: 0.15%, the balance is water.

[0038] Mix the graphene aqueous solution, water-based resin and part of the water into the mixer, control the speed at 2000 rpm, and stir for 30 minutes; then add polyvinylpyrrolidone PVP, polydimethylsiloxane Ls-3110, Dimethylethanolamine DEMA, polyacrylate thickener DN-2222, modified polycarbodiimide crosslinker XR-5580, ...

Embodiment 2

[0040] The present embodiment provides a kind of multifunctional coating that is applicable to battery box, and its raw material comprises: graphene aqueous solution 45% (the mass content of graphene is 10%), water-based resin 30% (wherein polyurethane RU -71-035 and acrylic resin AC-106 mixed at a mass ratio of 4:3), polyvinylpyrrolidone PVP: 0.9%, polydimethylsiloxane Ls-3110: 0.5%, dimethylethanolamine DEMA: 0.6%, Polyacrylate thickener DN-2222: 0.8%, modified polycarbodiimide crosslinking agent XR-5580: 1.0%, polydimethylsiloxane wear agent DC-51: 5%, silicone resistance Combustion agent DC-8008: 15%, oily defoamer T-501: 0.15%, the balance is water.

[0041] Mix the graphene aqueous solution, water-based resin and part of the water into the mixer, control the speed at 2000 rpm, and stir for 30 minutes; then add polyvinylpyrrolidone PVP, polydimethylsiloxane Ls-3110, Dimethylethanolamine DEMA, polyacrylate thickener DN-2222, modified polycarbodiimide crosslinker XR-5580, ...

Embodiment 3

[0043] The present embodiment provides a kind of multifunctional coating that is applicable to battery box, and its raw material comprises: graphene aqueous solution 45% (the mass content of graphene is 10%), water-based resin 30% (wherein polyurethane RU -71-035 and acrylic resin AC-106 mixed at a mass ratio of 12:7), polyvinylpyrrolidone PVP: 0.9%, polydimethylsiloxane Ls-3110: 0.5%, dimethylethanolamine DEMA: 0.6%, Polyacrylate thickener DN-2222: 0.8%, modified polycarbodiimide crosslinking agent XR-5580: 1.0%, polydimethylsiloxane wear agent DC-51: 5%, silicone resistance Combustion agent DC-8008: 15%, oily defoamer T-501: 0.15%, the balance is water.

[0044] Mix the graphene aqueous solution, water-based resin and part of the water into the mixer, control the speed at 2000 rpm, and stir for 30 minutes; then add polyvinylpyrrolidone PVP, polydimethylsiloxane Ls-3110, Dimethylethanolamine DEMA, polyacrylate thickener DN-2222, modified polycarbodiimide crosslinker XR-5580,...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com