Low-solid-content drilling fluid used for hydrocarbon bearing shaly sands and preparation method of low-solid-content drilling fluid

A argillaceous sandstone, low solid phase technology, applied in the field of low solid phase drilling fluid and its preparation, can solve the problems of poor quality shale that cannot be precipitated, rapid increase in drilling fluid density, difficult solid phase control, etc., and achieves anti-drill cuttings pollution The effect of strong capacity, small reservoir damage and low filtration loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

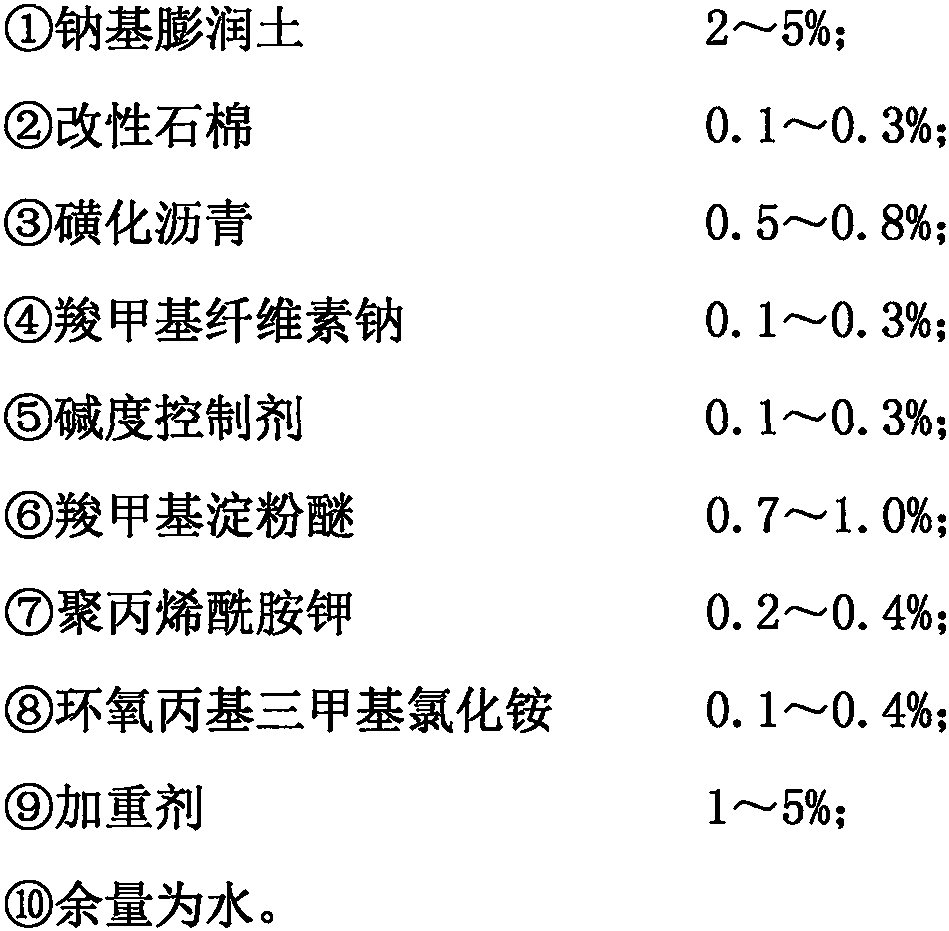

Method used

Image

Examples

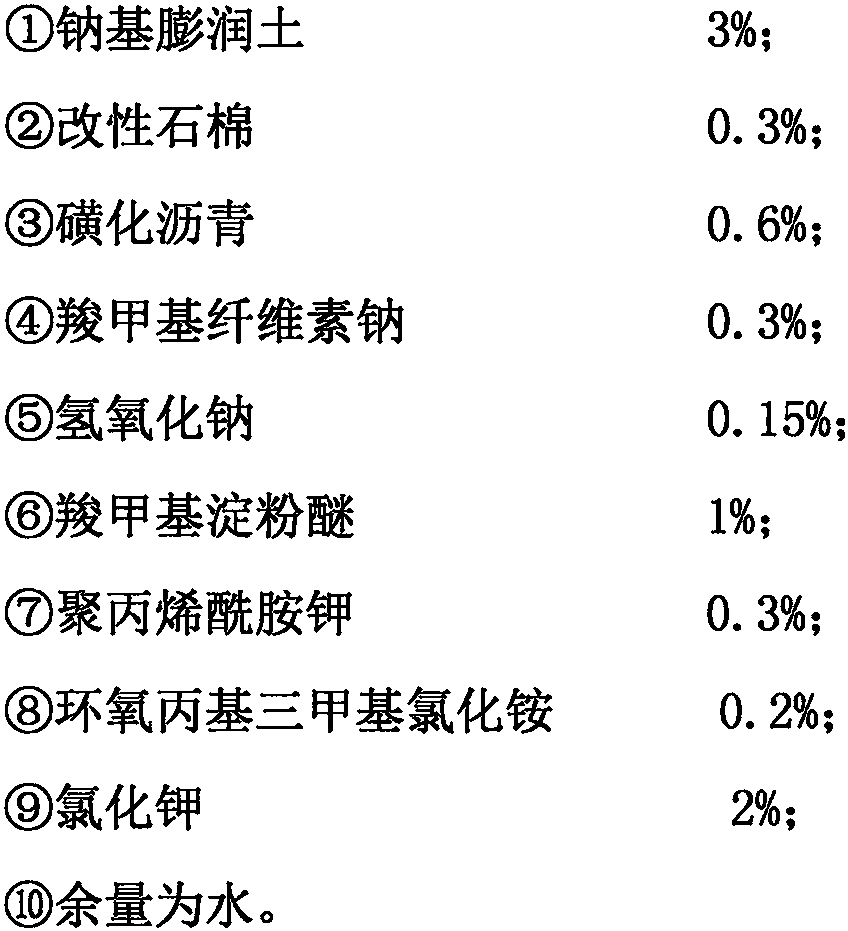

Embodiment

[0017]

[0018] This drilling fluid is carried out by the compound of above-mentioned ratio under normal temperature and pressure according to following procedure:

[0019] (1) Use soda ash to remove Ca in the mixing water 2+ (per removal of 1mg / l of Ca 2+ , need to use soda ash 4.29g / m 3 );

[0020] (2) Get the slurry preparation water, add the above-mentioned ratio of sodium bentonite, modified asbestos, fully stir with a stirrer, leave standstill for 24 hours to form the base slurry;

[0021] (3) Add the weighting agent of the above ratio to make the drilling fluid density meet the requirement;

[0022] (4) Add the sulfonated pitch, sodium carboxymethyl cellulose, carboxymethyl starch ether, potassium polyacrylamide, glycidyltrimethyl ammonium chloride of the above proportioning successively, stir to make it fully dissolve;

[0023] (5) Add alkalinity control agent to adjust pH to 8.5-9.5.

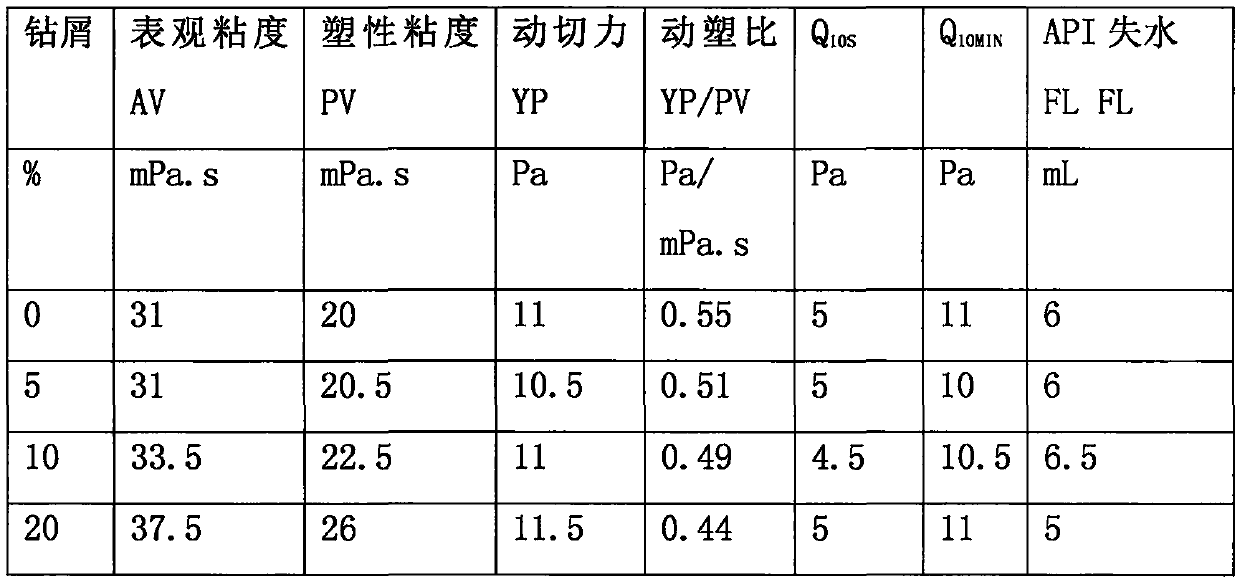

[0024] The drilling fluid prepared according to the above ratio and method ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Plastic viscosity | aaaaa | aaaaa |

| Funnel viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com