Method for storing natural gas hydrate

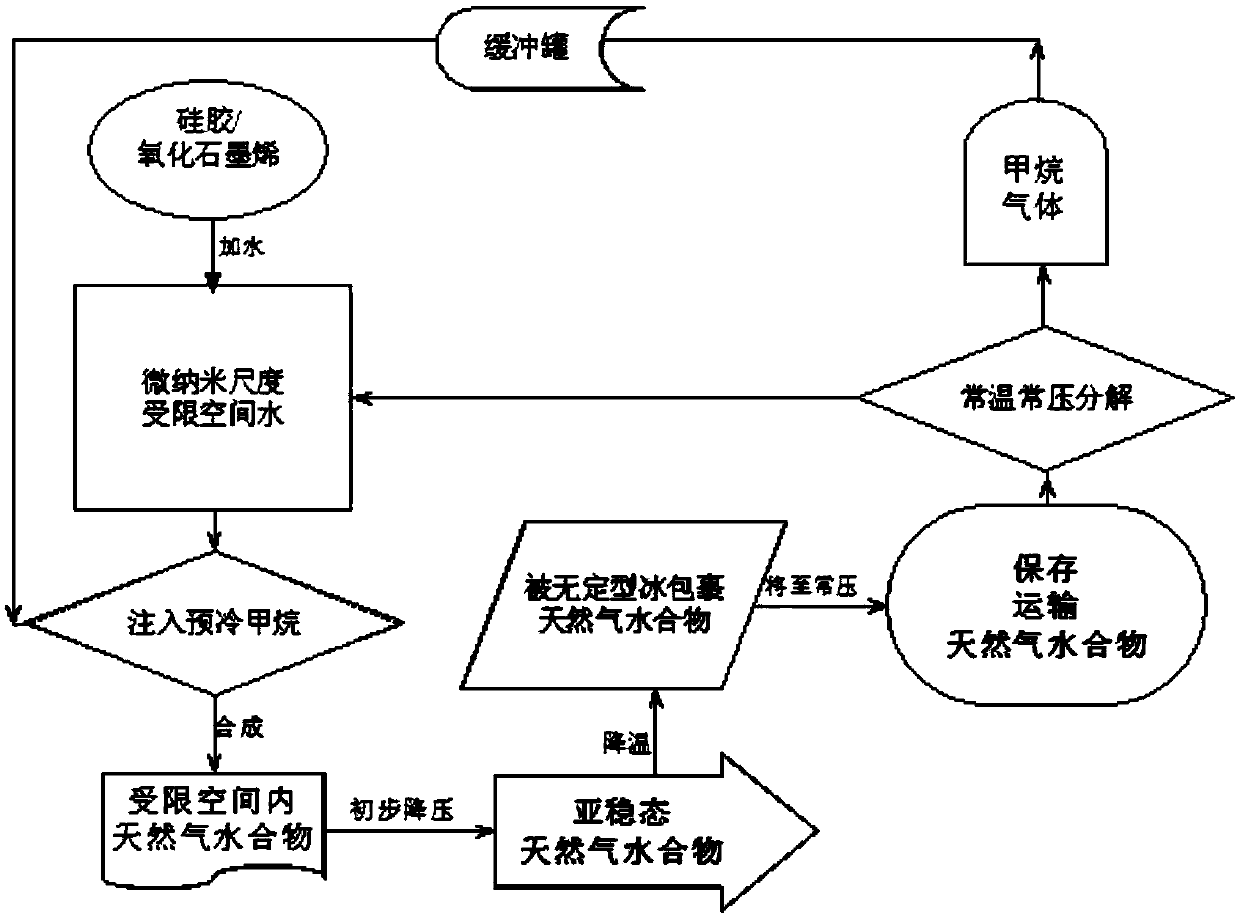

A natural gas and hydrate technology, applied in gas fuel, petroleum industry, fuel and other directions, can solve the problems of poor density recovery, slow hydrate formation rate, and high gas storage capacity, achieve good density, reduce storage and transportation costs, increase safety effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0037] Using columnar chromatography silica gel with a pore size of about 20nm and a particle size of about 0.1-0.3mm, distilled water and methane gas as experimental materials, the above-mentioned steps are used to synthesize, store and decompose methane hydrate samples for natural gas hydrate storage and transportation tests experiment.

[0038] To synthesize aqueous columnar chromatography silica gel, mix the same amount of water as the pore volume of columnar chromatography silica gel with columnar chromatography silica gel, fully mix and stir. Seal and stand for 5 days to ensure that the distilled water is absorbed by the pores of the column chromatography silica gel. Aqueous column chromatography silica gel is put into the reaction kettle. Remove the air in the reactor and pipeline by vacuuming. The temperature of the reactor is lowered below the equilibrium point of the hydrate phase, and has a supercooling degree above 5K, and at the same time, the gas in the buffer ...

Embodiment 2

[0043] With a thickness of 0.55-1.2nm, a diameter of 0.5-3μm, and a specific surface area of 200-480m 2 .g –1 , pore volume 1.3cm 3 .g –1 The three-dimensional porous graphene oxide, distilled water and methane gas are used as experimental materials, and the method steps of the invention are used to carry out the synthesis, preservation and decomposition of methane gas to test the natural gas hydrate storage and transportation of methane hydrate samples.

[0044] The three-dimensional porous graphene oxide structure contains a large number of oxygen-containing functional groups such as hydroxyl, carboxyl and epoxy groups, making graphene oxide very easy to absorb water. The dry three-dimensional porous graphene oxide is loose and porous powder, which is sponge-like and dissolves after adding water. Quickly and completely, almost immediately restore the original sol properties.

[0045] Synthesis of Aqueous Three-dimensional Porous Graphene Oxide. Mix the same amount of w...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Aperture | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com