Preparation method of Fe2B intermetallic compound wear-resistant coating

A technology of intermetallic compound and wear-resistant coating, which is applied in the field of surface coating and its preparation, can solve the problems of cumbersome process, high energy consumption, and easy formation of teardrop-shaped surface features, so as to avoid energy accumulation and coating composition Uniform, clear heat effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

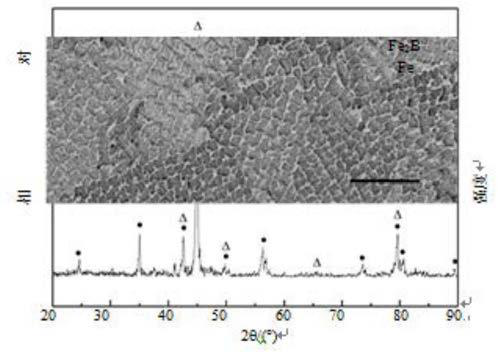

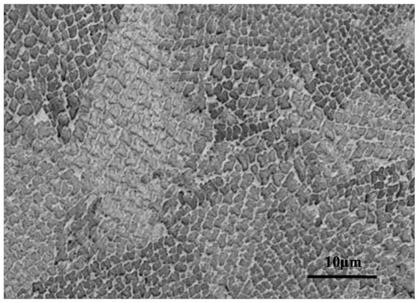

[0020] The mixed powder of Fe-B alloy: 45% by mass and Fe: 55% by mass is used as the raw material of the coating, and the powder particle size is 48-80 μm. Synchronous powder feeding laser cladding is used to prepare three-layer cladding coatings: (1) The surface of the substrate to be cladding is polished and smooth, and the oil and rust on the surface are removed, and stored in a dry state; (2) The fiber laser is used for cladding and melting. Argon gas is used for protection during the cladding process. The specific process parameters of the cladding: the laser power of the first layer is set to 120W, starting from the second layer, the laser power of each layer is set to 94% of the previous layer, and the scanning rate is 4mm / s, the laser spot diameter is 0.1mm, the offset is 0.16mm, the defocus is 5mm, and the shielding gas flow rate is 6L / min. The final coating structure is Fe 2 B and Fe, the coating has a good metallurgical bond with the substrate. After micro Vickers...

Embodiment 2

[0022] The mixed powder of Fe-B alloy: 60% by mass and Fe: 40% by mass is used as the raw material of the coating, and the powder particle size is 48-80 μm. The 4-layer cladding coating is prepared by synchronous powder feeding laser cladding: (1) The surface of the substrate to be cladding is polished and smooth, and the oil and rust on the surface are removed, and stored in dry; (2) The fiber laser is used for cladding and melting. Argon gas is used for protection during the cladding process. The specific process parameters of the cladding: the laser power of the first layer is set to 150W, starting from the second layer, the laser power of each layer is set to 92% of the previous layer, and the laser scanning rate 5mm / s, the laser spot diameter is 0.1mm, the offset is 0.16mm, the defocus is 5mm, and the shielding gas flow rate is 6L / min. The final coating structure is Fe 2 B and Fe, the coating has a good metallurgical bond with the substrate. After micro Vickers hardness t...

Embodiment 3

[0024] The mixed powder of Fe-B alloy: 75% by mass and Fe: 25% by mass is used as the raw material of the coating, and the powder particle size is 48-80 μm. Synchronous powder feeding laser cladding is used to prepare 5-layer cladding coatings: (1) The surface of the substrate to be cladding is polished and smooth, and the oil and rust on the surface are removed, and stored in a dry state; (2) The fiber laser is used for cladding and melting Argon gas is used for protection during the cladding process. The specific process parameters of the cladding: the laser power of the first layer is set to 180W, starting from the second layer, the laser power of each layer is set to 90% of the previous layer, and the laser scanning rate 6mm / s, laser spot diameter is 0.1mm, offset is 0.16mm, defocus is 5mm, and shielding gas flow rate is 6L / min. The final coating structure is Fe 2 B and Fe, the coating has a good metallurgical bond with the substrate. . After micro Vickers hardness test a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| wear rate | aaaaa | aaaaa |

| wear rate | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com