Preparation process for graphene composite carbon-based high-temperature film

A graphene composite and preparation process technology, applied in graphene, sustainable manufacturing/processing, nano-carbon and other directions, can solve problems such as difficult dispersion and easy flocculation, achieve simple production method, solve aggregation overheating, and market promotion and application effects obvious effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

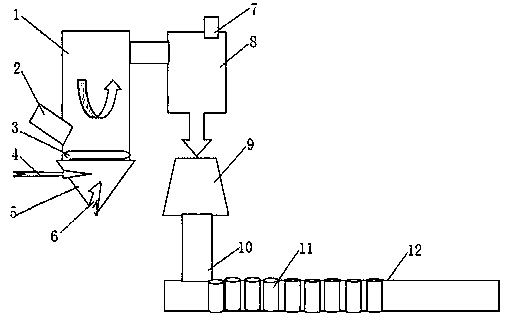

Image

Examples

Embodiment 1

[0051]A preparation process for a graphene composite carbon-based high-temperature film, comprising the following steps:

[0052] (1) Making flake graphite powder

[0053] Select flake graphite with a purity of 99% and a particle size of 1-2 mm, and ball mill it to a particle size of 20 μm in a dry environment at room temperature to obtain fine-grained graphite flake powder;

[0054] (2) Select a graphene dispersant, the selected material is a graphene oxide dispersion liquid with a purity of 99wt%, a sheet diameter of 3μm, and a concentration of 10mg / ml;

[0055] (3) Choose a specific gravity between 0.96-0.97 and a viscosity of 100±8mm 2 / s of methyl silicone oil;

[0056] (4) Add the above-mentioned graphene dispersant to the fine-grained flake graphite powder obtained in (1) at a mass ratio of 0.8% and methyl silicone oil at a mass ratio of 0.2%, and stir for 60 minutes at normal temperature and pressure , stirring speed is 400r / min, obtains the incompletely mixed graph...

Embodiment 2

[0093] A preparation process for a graphene composite carbon-based high-temperature film, comprising the following steps:

[0094] (1) Making flake graphite powder

[0095] Select flake graphite with a purity of about 99% and a particle size of 1 mm, and ball mill it to a particle size of 30 μm in a dry environment at room temperature to obtain fine-grained graphite flake powder;

[0096] (2) Select a graphene dispersant, the selected material is a graphene oxide dispersion liquid with a purity of 99wt%, a sheet diameter of 5μm, and a concentration of 10mg / ml;

[0097] (3) Choose a specific gravity of 0.96 and a viscosity of 100±8mm 2 / s of methyl silicone oil;

[0098] (4) Add the above-mentioned graphene dispersant to the fine-grained flake graphite powder obtained in (1) at a mass ratio of 0.5% and methyl silicone oil at a mass ratio of 0.5%, and stir for 60 minutes at normal temperature and pressure , the stirring speed is 300r / min, and the graphene-carbon matrix compos...

Embodiment 3

[0105] The preparation technology of graphene composite carbon-based high-temperature film comprises the following steps:

[0106] (1) Making flake graphite powder

[0107] Select flake graphite with a purity of about 99% and a particle size of 2 mm, and ball mill it to a particle size of 40 μm in a dry environment at room temperature to obtain fine-grained graphite flake powder;

[0108] (2) Select the graphene dispersant, the selected material is graphene oxide dispersion liquid, the purity is 99wt%, wherein the purity is 99wt%, the sheet diameter is 5μm, and the concentration is 10mg / ml;

[0109] (3) Choose a specific gravity between 0.96-0.97 and a viscosity of 100±8mm 2 / s of methyl silicone oil;

[0110] (4) Add the above-mentioned graphene dispersant to the fine-grained flake graphite powder obtained in (1) at a mass ratio of 0.5% and methyl silicone oil at a mass ratio of 0.5%, and stir for 60 minutes at normal temperature and pressure , the stirring speed is 500r / m...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com