Method for producing dry spinning acrylic 1.33dtex short fiber

A production method and technology of dry acrylic fibers, which are applied in the fields of chemical characteristics of fibers, complete sets of equipment for producing artificial threads, textiles and papermaking, etc., can solve the problems of not mass-producing 1.33dtex staple fibers and inability to produce them, and achieve sustainable development. , The effect of smooth production and stable product quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

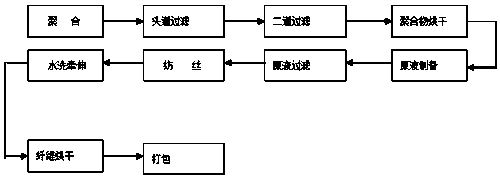

[0026] Refer to attached figure 1 The specific preparation steps are polymerization, primary filtration, secondary filtration, polymer drying, stock solution preparation, stock solution filtration, spinning, washing and drawing, fiber drying, and packaging;

[0027] In the polymerization step of this embodiment, the polymer obtained by polymerizing three monomers of acrylonitrile, methyl acrylate and sodium styrene sulfonate is used as the spinning stock solution, wherein the mass ratio of acrylonitrile, methyl acrylate and sodium styrene sulfonate is 93.5:6:0.8; solution polymerization is adopted, and the solvent used is a composite solvent prepared from dimethylformamide and sodium thiocyanate at a mass ratio of 88:12; the polymerization temperature is 68°C;

[0028] In this embodiment, the temperature of the spinning tunnel is controlled during spinning, washing and drawing: the air chamber temperature is 330°C, the temperature of the vertebral body is 205°C, the temperatur...

Embodiment 2

[0030] Refer to attached figure 1 The specific preparation steps are polymerization, primary filtration, secondary filtration, polymer drying, stock solution preparation, stock solution filtration, spinning, washing and drawing, fiber drying, and packaging;

[0031] In the polymerization step of this embodiment, the polymer obtained by polymerizing three monomers of acrylonitrile, methyl acrylate and sodium styrene sulfonate is used as the spinning stock solution, wherein the mass ratio of acrylonitrile, methyl acrylate and sodium styrene sulfonate is 93:7:0.7; solution polymerization is adopted, and the solvent used is a composite solvent prepared by dimethylformamide and sodium thiocyanate at a mass ratio of 86:14; the polymerization temperature is 65°C;

[0032] In this embodiment, the temperature of the spinning tunnel is controlled during spinning, washing and drawing: the air chamber temperature is 328°C, the temperature of the vertebral body is 204°C, the temperature at...

Embodiment 3

[0034] Refer to attached figure 1 The specific preparation steps are polymerization, primary filtration, secondary filtration, polymer drying, stock solution preparation, stock solution filtration, spinning, washing and drawing, fiber drying, and packaging;

[0035] In the polymerization step of this embodiment, the polymer obtained by polymerizing three monomers of acrylonitrile, methyl acrylate and sodium styrene sulfonate is used as the spinning stock solution, wherein the mass ratio of acrylonitrile, methyl acrylate and sodium styrene sulfonate is 94:5:1; solution polymerization is adopted, and the solvent used is a composite solvent prepared with dimethylformamide and sodium thiocyanate at a mass ratio of 92:8; the polymerization temperature is 70°C;

[0036]In this embodiment, the temperature of the spinning tunnel is controlled during spinning, washing and drafting: the temperature of the air chamber is 332°C, the temperature of the vertebral body is 206°C, the temperat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com