7d porous hollow fiber and its preparation method and application

A hollow and fiber technology, applied in the field of polyester staple fibers, can solve the problems of fiber performance that cannot meet the needs of the industry, poor crimp rate, etc., and achieves the effect of improving the clustering, increasing the crimping potential energy, and uniform thickness.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0033] The present invention provides a kind of preparation method of 7D porous hollow fiber, and this preparation method comprises the following steps:

[0034] Step S01. Melting and extruding the spinning raw material to obtain a melt with a viscosity of 0.70dl / g-0.78dl / g;

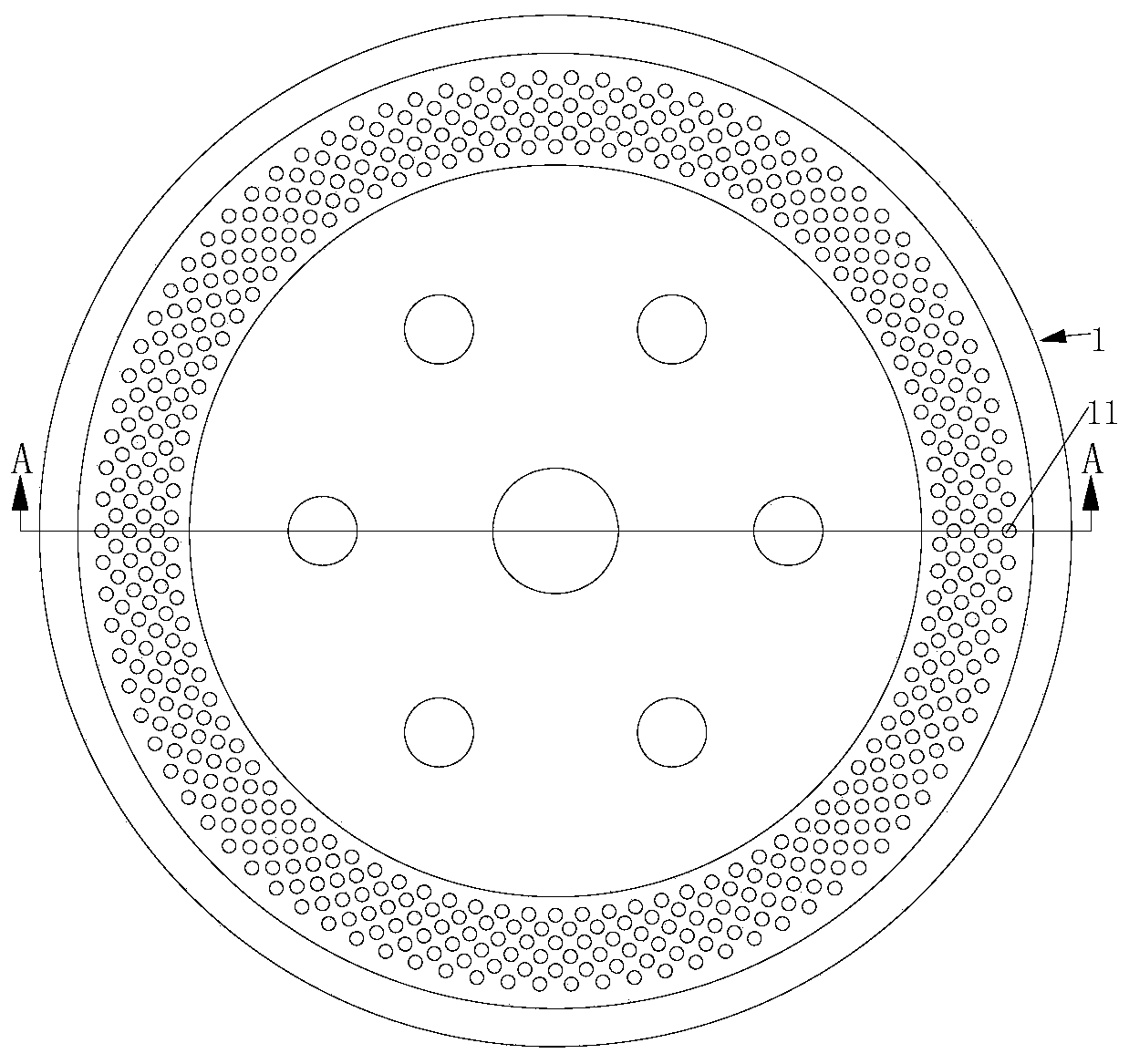

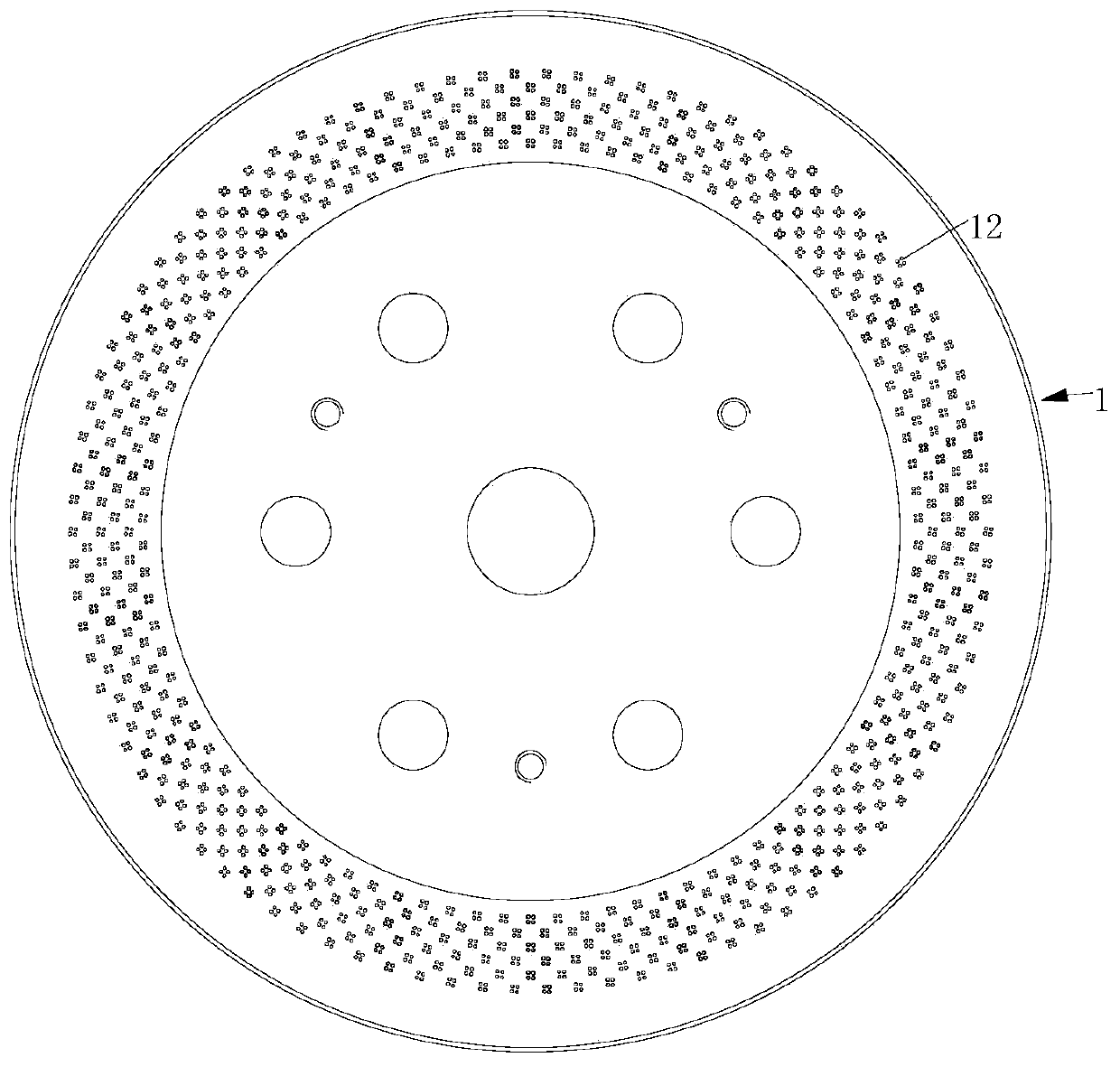

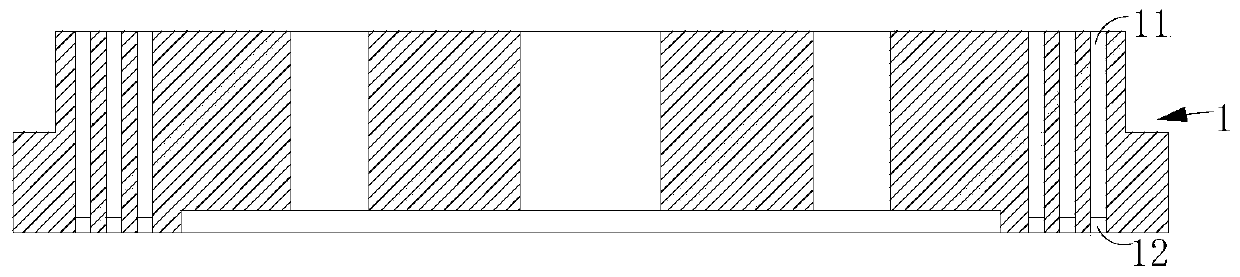

[0035] Step S02. The melt is sprayed from the spinneret hole of the 4-hole hollow spinneret to obtain the primary fiber, and the primary fiber is cooled by the circular air blowing cooling method, and the height of the cooling point during cooling is 6.5cm ~7.5cm, water mist with a particle size of ≤100μm is passed into the cooling air pipe during cooling of the surrounding air, the temperature of the surrounding air is 22°C-24°C, and the temperature of the fiber on the windward side is lower than that on the leeward side by 3°C-4 ℃, the relative humidity of the surrounding air is 90±10%, and the wind speed is (7.0~8.0)m / s;

[0036]Step S03. Winding, bundling, water-bath drawing and steam drawing the as...

Embodiment 1~26

[0057] In order to save space, the parameters involved in the preparation methods of Examples 1 to 26 are listed in Table 1. The specific preparation process is prepared according to the instructions in the manual. The raw material is recycled polyester bottle flakes, and the viscosity of the melt is 0.70dl / g~0.78dl / g.

[0058] Table 1 Examples 1-26 preparation process parameters (water mist particle size ≤ 100 μm)

[0059]

PUM

| Property | Measurement | Unit |

|---|---|---|

| number of curls | aaaaa | aaaaa |

| Curvature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com